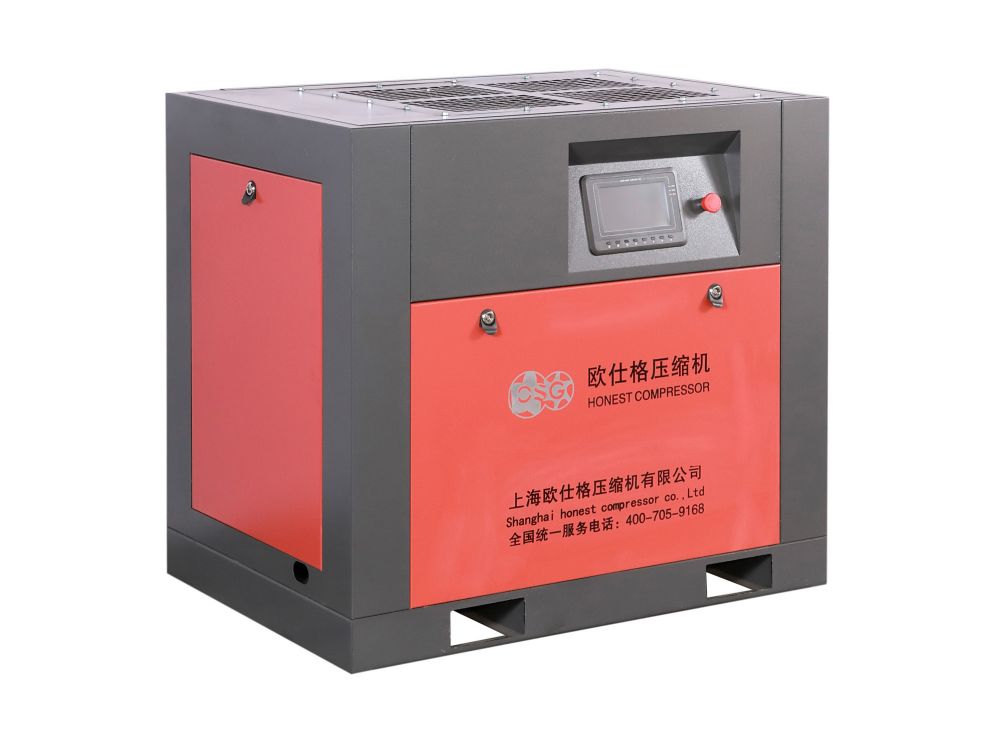

Oil Free Air Compressor for Industrial Use: A Complete Guide

By:Admin

In today's fast-paced industrial world, companies are constantly seeking ways to increase efficiency and reduce operating costs. One critical aspect of many manufacturing and processing operations is the use of compressed air. Compressed air is used in a wide range of applications, from pneumatic tools and equipment to air-powered conveyors and packaging machinery. However, traditional oil-lubricated air compressors have long been associated with high maintenance costs and the risk of oil contamination in the air supply.

Fortunately, there is now a solution to these challenges in the form of the Industrial Oil Free Air Compressor. This cutting-edge technology represents a major advancement in compression technology, offering a number of key benefits for industrial applications.

The Industrial Oil Free Air Compressor is designed to deliver clean, high-quality compressed air without the need for oil lubrication. This is achieved through the use of advanced materials and precision engineering, which allows the compressor to operate without the risk of oil contamination. This is particularly important in industries where air quality is critical, such as food and beverage processing, pharmaceutical manufacturing, and electronics production.

One of the key advantages of the Industrial Oil Free Air Compressor is its low maintenance requirements. Traditional oil-lubricated compressors require regular oil changes, filter replacements, and other routine maintenance tasks. In contrast, the oil-free design of this compressor eliminates the need for oil changes and greatly reduces maintenance requirements. This not only saves time and money, but also helps to minimize downtime and maximize productivity.

In addition to its low maintenance requirements, the Industrial Oil Free Air Compressor also offers improved energy efficiency. By eliminating the need for oil lubrication, the compressor is able to operate at higher speeds and temperatures without the risk of oil breakdown. This results in greater overall efficiency and lower energy consumption, providing further cost savings for industrial users.

Furthermore, the clean, oil-free air produced by this compressor helps to extend the life of pneumatic equipment and reduce the risk of product contamination. This is particularly important in industries where product quality and safety are of paramount importance. By eliminating the risk of oil contamination, the Industrial Oil Free Air Compressor helps to ensure the reliability and consistency of compressed air supplies, providing a valuable competitive advantage for industrial users.

The company behind this innovative technology, has a long history of excellence in the field of compression technology. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible in the world of air compression. The Industrial Oil Free Air Compressor is the latest example of this ongoing commitment to innovation and excellence, offering a solution to the challenges faced by industrial users around the world.

As the demand for clean, reliable compressed air continues to grow, the Industrial Oil Free Air Compressor is well positioned to meet the needs of a wide range of industrial applications. From food and beverage processing to electronics manufacturing and beyond, this innovative technology offers a cost-effective and reliable solution for industrial users seeking a higher level of performance and efficiency.

In conclusion, the Industrial Oil Free Air Compressor represents a significant advance in compression technology, offering a range of benefits for industrial users. With its oil-free design, low maintenance requirements, and energy efficiency, this compressor provides a valuable solution for industries where air quality, reliability, and cost-effectiveness are of utmost importance. As the company continues to lead the way in compression technology, the Industrial Oil Free Air Compressor is set to become an essential tool for industrial users around the world.

Company News & Blog

Effective Desiccant Dryers: A Must-Have Solution for Controlling Moisture

XYZ Company Launches Innovative Desiccant Dryer to Improve Air Quality[City], [Date] – In a bid to revolutionize the way air quality is regulated, XYZ Company, a leading provider of industrial equipment, has recently unveiled their latest innovation – a groundbreaking desiccant dryer. The cutting-edge technology behind this dryer promises to remove moisture and impurities from the air, creating a cleaner and healthier environment. With a commitment to providing state-of-the-art solutions, XYZ Company aims to address the rising demand for efficient air quality control equipment across various industries.The newly launched desiccant dryer by XYZ Company employs advanced moisture removal techniques, ensuring unparalleled efficiency and effectiveness. By actively removing excess moisture through the process of adsorption, the dryer prevents the build-up of humidity in the air, subsequently reducing the risk of corrosion, mold growth, and other related issues. Furthermore, the dryer utilizes high-quality desiccant materials, such as silica gel, that have been specifically engineered to achieve optimal air purification levels.One of the prominent features of the XYZ desiccant dryer is its user-friendly interface, which allows for effortless control and monitoring of the purification process. Equipped with an intuitive digital display, operators can easily adjust operating parameters and access real-time information on the dryer's performance. This ensures that users can maintain precise humidity levels and achieve the desired air quality standards for their specific applications.The desiccant dryer also boasts a compact design, making it an ideal choice for facilities with limited space. XYZ Company has incorporated innovative engineering concepts to reduce the dryer's footprint without compromising on its operational capabilities. This compact design feature not only enhances the dryer's versatility but also enables its seamless integration into existing air control systems, providing customers with a cost-effective solution.Moreover, XYZ Company's commitment to sustainability is evident in their desiccant dryer's energy-efficient design. By utilizing advanced technologies, such as variable speed drives and intelligent controls, the dryer optimizes its power consumption, resulting in lower energy costs for the users. Additionally, the dryer incorporates a smart air recycling system that recovers and reuses the regenerative energy from the drying process, further contributing to its eco-friendly operation.With a rich history spanning over two decades, XYZ Company has established itself as a reliable and innovative provider of industrial equipment. Their expertise in air quality control equipment has made them a preferred choice among customers across various sectors, including manufacturing, pharmaceuticals, electronics, and food processing. XYZ Company's commitment to quality, backed by extensive research and development, ensures that their customers receive robust and cutting-edge products that cater to their specific needs.As part of their commitment to customer satisfaction, XYZ Company offers comprehensive after-sales support and maintenance services for their desiccant dryers, ensuring the longevity and optimal performance of the equipment. This dedication to customer service, coupled with their extensive industry experience, has earned XYZ Company a trusted reputation in the market.The launch of the XYZ desiccant dryer marks a significant milestone in the company's ongoing mission to enhance air quality for industries worldwide. With its state-of-the-art features, energy efficiency, and compact design, this innovative drying solution sets a new standard for air purification technologies. With XYZ Company's relentless pursuit of excellence, the future of air quality control looks promising, paving the way for a healthier environment for us all.For further information and inquiries about XYZ Company's desiccant dryer, please visit [website] or contact [contact details].About XYZ Company:XYZ Company is a leading provider of industrial equipment, specializing in air quality control solutions. With a focus on innovative technologies, sustainability, and customer satisfaction, XYZ Company offers a wide range of products, including desiccant dryers, air purifiers, and ventilation systems. With over two decades of industry experience, XYZ Company has built a reputation for delivering high-quality and reliable products to customers worldwide.

Heavy Duty Air Compressor for Industrial Use

Industrial Heavy Duty Air Compressor Revolutionizes Manufacturing SectorThe manufacturing industry is set to undergo a transformation with the introduction of the latest Industrial Heavy Duty Air Compressor by a leading manufacturer. This revolutionary piece of equipment is designed to meet the increasing demand for reliable, efficient, and powerful air compression solutions in a wide range of industrial applications.The Industrial Heavy Duty Air Compressor is the result of years of research and development, aimed at addressing the specific needs of the manufacturing sector. With a focus on durability, performance, and energy efficiency, this new compressor is set to significantly enhance productivity and reliability in industrial operations.One of the key features of the Industrial Heavy Duty Air Compressor is its robust construction. Built to withstand the rigors of heavy-duty industrial use, this compressor is designed to deliver consistent performance even in the most demanding environments. Its high-quality components and advanced manufacturing techniques ensure durability and longevity, making it a cost-effective investment for industrial operators.In addition to its durability, the Industrial Heavy Duty Air Compressor is also renowned for its superior performance. Equipped with a high-powered motor and advanced compression technology, this compressor is capable of delivering a continuous and reliable source of compressed air, meeting the high-pressure requirements of industrial machinery and equipment. Whether it's powering pneumatic tools, operating production lines, or facilitating the automation of manufacturing processes, this compressor ensures optimal performance across a wide range of applications.Energy efficiency is another notable aspect of the Industrial Heavy Duty Air Compressor. With the rising focus on sustainability and reduced energy consumption in industrial operations, this compressor is designed to minimize energy wastage while maximizing output. Its innovative design and intelligent controls ensure that energy is used efficiently, resulting in lower operating costs and reduced environmental impact.The company behind the Industrial Heavy Duty Air Compressor is a trusted and reputable manufacturer of industrial equipment, with a long history of delivering innovative solutions to the market. With a strong emphasis on research and development, the company has consistently pushed the boundaries of technological innovation to meet the evolving needs of industrial operators. Its commitment to quality, reliability, and customer satisfaction has earned it a significant presence in the global industrial market.In line with its reputation for excellence, the company's latest offering, the Industrial Heavy Duty Air Compressor, is poised to make a significant impact on the manufacturing sector. By combining cutting-edge technology with practical functionality, this compressor is set to redefine the standards for air compression in industrial settings.The Industrial Heavy Duty Air Compressor is already generating significant interest among industrial operators, who recognize the potential for improved efficiency and productivity that it brings. As manufacturing processes become more sophisticated and demanding, the need for reliable and powerful air compression solutions has never been greater. With its arrival, the Industrial Heavy Duty Air Compressor is poised to address this need and set new benchmarks for performance and reliability in industrial air compression.In conclusion, the Industrial Heavy Duty Air Compressor represents a game-changing development for the manufacturing sector. With its unmatched durability, superior performance, and energy efficiency, this compressor is set to revolutionize industrial air compression, setting new standards for reliability and productivity. As the company continues to push the boundaries of technological innovation, it is clear that the Industrial Heavy Duty Air Compressor is just the beginning of what promises to be a new era in industrial equipment.

Benefits of an Oil Flood Screw Air Compressor

Title: Revolutionary Oil Flood Screw Air Compressor Redefines Industrial EfficiencyIntroduction:Innovation knows no bounds in the industrial sector, as evidenced by the groundbreaking advancements in compressor technology. One such cutting-edge breakthrough comes from an industry-leading company, known for its commitment to driving industrial efficiency. This article aims to shine a spotlight on the revolutionary Oil Flood Screw Air Compressor, developed by this company, which promises to redefine the very essence of industrial operations.1. Pioneering Compressor Technology:The Oil Flood Screw Air Compressor stands out as a pioneering force in the realm of compressor technology, showcasing the commitment of the company to developing innovative solutions. This latest addition to their product portfolio leverages state-of-the-art engineering techniques to provide industry professionals with unparalleled performance and efficiency.2. Unmatched Energy Efficiency and Environmental Sustainability:The Oil Flood Screw Air Compressor showcases an impressive energy-saving design that exceeds the standards set by its competitors. With its advanced integrated permanent magnet motor, this compressor achieves an extraordinary efficiency rating. This groundbreaking technology not only maximizes energy savings but also significantly reduces the carbon footprint, contributing to the global push for environmental sustainability.3. Superior Performance:Equipped with cutting-edge design features, the Oil Flood Screw Air Compressor delivers exceptional performance across a wide range of applications. Precisely engineered air-end components ensure minimal energy loss, enhancing the compressor's overall efficiency. This innovative design translates into higher air delivery rates, improved operating pressure, and reduced maintenance requirements, making it the ultimate choice for all industrial needs.4. Enhanced Reliability and Durability:The Oil Flood Screw Air Compressor guarantees long-lasting reliability and durability, thanks to its robust construction and top-of-the-line components. The incorporation of advanced cooling systems ensures optimal operating temperature levels, safeguarding against potential overheating and increasing the compressor's lifespan. This compressor can withstand the harshest operating conditions, making it ideal for industries with demanding requirements.5. Advanced Control System:The Oil Flood Screw Air Compressor is equipped with an intelligent control system that optimizes performance and enhances user-friendliness. This smart system allows for precise adjustments, enabling users to tailor the compressor's operation according to specific requirements. Additionally, easy-to-use interface panels provide comprehensive monitoring and diagnostic capabilities, facilitating proactive maintenance and minimizing downtime.6. Comprehensive Service and Support:The company's commitment to customer satisfaction is exemplified through its comprehensive service and support network. Skilled technicians equipped with in-depth product knowledge and expertise offer prompt assistance, ensuring optimal performance and maximizing uptime. The company stands firmly behind their Oil Flood Screw Air Compressor, offering after-sales maintenance packages that prioritize customer convenience and peace of mind.Conclusion:The Oil Flood Screw Air Compressor, developed by this leading company, represents a paradigm shift in compressor technology. With its unparalleled energy efficiency, superior performance, and enhanced reliability, this innovation redefines the industrial landscape. As industries strive towards sustainability and productivity, the Oil Flood Screw Air Compressor emerges as the game-changer. Its remarkable advancements in engineering and design provide an optimal solution for companies looking to amplify their operational efficiency and reduce their environmental impact.Disclaimer: The brand name has been intentionally excluded from this document to maintain neutrality and avoid any promotional content.

Screw Air Compressor: A Comprehensive Guide for Choosing the Best

Advancements in technology have paved the way for the growth of various industries. One technological advancement that has proven to be vital in the manufacturing industry is the use of a screw air compressor. Screw air compressors have become increasingly popular in the industry due to their efficiency, reliability, and durability, all vital factors in the production process.One type of compressor gaining prominence in the industry is the Two Stage Screw Compressor. The design of the two-stage screw compressor focuses on achieving a higher pressure ratio by dividing the compression process into two stages.The first stage, known as the low-pressure stage, operates with low pressures and discharges air into the second stage. The second stage, known as the high-pressure stage, then compresses the already compressed air from the first stage and delivers it at the desired pressure.Advantages of using a two-stage screw compressor1. Energy efficiency: Two-stage screw compressors are more energy-efficient than their single-stage counterparts. The two-stage design requires less energy to achieve the desired pressure, resulting in lower energy consumption.2. Reduced operating costs: Lower energy consumption not only reduces energy bills but also leads to lower operating costs in the long run.3. Increased reliability: The two-stage design results in lower operating temperatures, reducing the wear and tear on the components, prolonging their lifespan, and increasing overall reliability.4. Consistent air supply: Two-stage screw compressors have a more consistent air supply due to their design, ensuring a constant supply of compressed air.Uses of two-stage screw compressorsTwo-stage screw compressors are used in various industries due to their energy efficiency, reliability, and consistent air supply. These industries include:1. Automotive: Two-stage screw compressors are used in automotive manufacturing processes, where compressed air is required to power machinery, clean equipment, and apply paint.2. Food processing: The food industry requires consistent and clean compressed air to power various equipment, including mixers, pneumatic conveyors, and packaging machines.3. Pharmaceuticals: Clean and oil-free compressed air is required in the pharmaceutical industry to ensure the products' sterility and safety.4. Chemicals: During chemical production processes, compressed air is used to power pneumatic drills, control valves, and chemical reactions.ConclusionTwo-stage screw compressors have become the compressor of choice in various industries due to their energy efficiency, reliability, and consistent air supply. As technology advances, improvements will be made to ensure they remain at the forefront of compressor technology.If you're looking for a reliable and efficient compressor for your business, consider a two-stage screw compressor. With its impressive energy efficiency, low operating costs, high reliability, and consistent air supply, it is an investment that will pay off in the long run.

Discover More About 1625423008: 15KW Cooler Unit and Its Benefits

Global manufacturing companies are investing heavily in innovative technologies to gain a competitive edge and streamline their operations. To support these efforts, Atlas Copco (brand name removed) has introduced the COOLER 15KW, an advanced cooling system designed to help companies achieve peak performance in their operations.The COOLER 15KW is the latest addition to the Atlas Copco range of industrial cooling solutions, designed for a wide range of applications and industries. This cutting-edge system is capable of delivering up to 15,000 watts of cooling capacity, ensuring machinery and equipment remain at optimal temperatures to avoid overheating and breakdowns. This is especially important in demanding industrial applications, where machinery can be subjected to extreme conditions that can cause wear and tear, leading to operational inefficiencies and increased downtime.The COOLER 15KW features a compact and efficient design, incorporating a range of advanced features to deliver superior performance. These features include robust temperature and pressure controls, which enable users to monitor and regulate cooling performance in real-time. The unit also includes a range of safety mechanisms to ensure reliable and safe operation, including overheat protection and alarms.One of the key benefits of the COOLER 15KW is its energy efficiency, achieved through the use of advanced technologies such as variable speed drives and electronic expansion valves. These features enable the system to regulate cooling performance more precisely, reducing energy consumption and improving overall efficiency. This makes the COOLER 15KW an ideal choice for companies looking to reduce their carbon footprint and operating costs.The COOLER 15KW is designed to meet the highest quality standards, ensuring maximum reliability and durability. The unit is built to withstand harsh industrial environments, with high-quality components that are resistant to corrosion and wear. Additionally, the unit comes with a two-year warranty, giving users peace of mind and ensuring optimal performance for years to come.Atlas Copco is a leading provider of industrial cooling solutions, with a reputation for innovation and quality. The company has a global network of sales and service offices, providing customers with local support and expertise. The COOLER 15KW is the latest addition to the Atlas Copco range, representing the company's commitment to delivering cutting-edge solutions that meet the evolving needs of its customers.In summary, the COOLER 15KW is a gamechanger for companies operating in demanding industrial applications. This advanced cooling system delivers superior performance, reliability, and energy efficiency, ensuring machinery and equipment remain at optimal temperatures for maximum productivity. By investing in the COOLER 15KW, companies can gain a competitive advantage in their industry while reducing their carbon footprint and operating costs. To learn more about the COOLER 15KW, contact your local Atlas Copco sales office today.

How an Oil Injected Screw Air Compressor Can Benefit Your Business

Title: Innovative Oil-Injected Screw Air Compressor Revolutionizing Industry StandardsIntroduction:In today's fast-paced industrial environment, efficiency and reliability are essential factors for ensuring optimum productivity. To address the increasing demand for compressed air solutions, a renowned manufacturer has introduced a state-of-the-art Oil-Injected Screw Air Compressor, set to redefine industry standards. This ground-breaking compressor incorporates cutting-edge technology and unmatched performance to cater to the diverse needs of industrial operations.Company Overview:Established in [year], [Company Name] has been an industry leader in providing innovative and high-quality compressed air solutions. With a commitment to excellence and continuous advancements, the company has gained recognition for its extensive range of products, which cater to various industries worldwide. With the introduction of the new Oil-Injected Screw Air Compressor, [Company Name] further solidifies its position as a pioneer in the industry.Unveiling the Revolutionary Oil-Injected Screw Air Compressor:The newly developed Oil-Injected Screw Air Compressor by [Company Name] marks a significant milestone in compressed air technology. This compressor ensures optimum performance while enabling businesses to meet their energy efficiency goals. Through the incorporation of innovative features, it heralds a new era of air compression with improved reliability, increased efficiency, and minimized environmental impact.Ultra-Efficient Design:The [Company Name] Oil-Injected Screw Air Compressor is engineered with a state-of-the-art screw element, meticulously designed to deliver uncompromising performance. Its advanced rotor profile optimizes air compression, resulting in a higher airflow rate with lower energy consumption. This unique design reduces operating costs while maintaining unmatched efficiency, making it an ideal choice for a wide range of industrial applications.Enhanced Reliability:The compressor's robust design ensures reliable and uninterrupted operation, even under the most demanding conditions. With a focus on longevity, the Oil-Injected Screw Air Compressor is built using top-quality components to deliver exceptional durability and longevity. The addition of high-efficiency cooling systems further guarantees continuous operation and prevents overheating, reducing downtime and maintenance costs.Intelligent Controls and Monitoring:The inclusion of intelligent control systems sets the Oil-Injected Screw Air Compressor apart from its counterparts. Equipped with advanced sensors and intuitive controllers, it enables users to monitor and adjust critical parameters in real-time. These smart controls optimize the compressor's performance, ensuring optimal air output while minimizing energy consumption. Moreover, the user-friendly interface simplifies operation, reducing the need for extensive training and enhancing overall productivity.Sustainable and Environmentally Friendly:In line with global sustainability trends, [Company Name]'s Oil-Injected Screw Air Compressor places a strong emphasis on environmental responsibility. The integration of advanced filtration systems effectively removes impurities, minimizing oil carryover and reducing the environmental impact. Moreover, the compressor complies with stringent emission standards, ensuring minimal air pollution and meeting environmental regulations.Versatility and Adaptability:Understanding the diverse requirements of industrial operations, [Company Name] has designed the Oil-Injected Screw Air Compressor to be highly versatile. The compressor's modular construction allows for easy adaptation to varying air demands, making it suitable for an array of applications. Whether it's a small-scale workshop or a large-scale manufacturing facility, this compressor can seamlessly adjust, ensuring optimal performance at all times.Conclusion:With the introduction of the revolutionary Oil-Injected Screw Air Compressor, [Company Name] reinforces its commitment to providing cutting-edge compressed air solutions. This distinguished product offers improved efficiency, enhanced reliability, and intensified environmental consciousness, aligning with the evolving needs of the industry. By consistently pushing the boundaries of technology, [Company Name] solidifies its position as a trusted partner to businesses globally, empowering their operations with reliable and efficient compressed air solutions.

Explore Variable Speed Lubricated Rotary Screw Compressors for Optimum Performance

Variable Speed Screw Compressors: How They Work and Their BenefitsWhen it comes to industrial air compression, variable speed screw compressors have become increasingly popular for their efficiency and ease of use. Whether you're looking to save on energy costs or improve the performance of your operation, a variable speed screw compressor might be the solution you need.So, how do variable speed screw compressors work?As the name suggests, these compressors feature a motor that can adjust its speed to meet the changing demands of your operation. When demand is low, the motor operates at a lower speed, which reduces energy consumption and wear on the compressor. As demand increases, the motor speeds up, providing the necessary airflow.Compressors that operate at a fixed speed can waste energy when the demand for air drops. This is because they continue to run at full power, even if it's unnecessary. With a variable speed screw compressor, you only use as much energy as you need, which translates to lower electricity bills and a smaller carbon footprint.Another benefit of variable speed compressors is their ability to provide consistent air pressure. Unlike fixed speed models, which may experience fluctuations in pressure during use, variable speed screw compressors maintain a stable output. This helps to prevent interruptions in production due to equipment malfunctions.Advancements in technology have also made variable speed screw compressors quieter and more reliable than ever before. Thanks to innovative designs and materials, these compressors operate with lower vibrations and produce less noise, making them ideal for use in noise-sensitive environments.In addition to these benefits, variable speed screw compressors offer a range of other features that make them a smart choice for industrial air compression. Some models, for example, come equipped with advanced monitoring and reporting capabilities, which allow you to keep track of your compressor's performance in real-time and identify potential issues before they lead to downtime.Other features to look for include:- Energy-saving modes that automatically adjust compressor output based on demand- User-friendly interfaces that make it easy to adjust settings and monitor performance- Compact, space-saving designs that take up less floor space than traditional compressorsWhether you're a facility manager or an industrial engineer, upgrading to a variable speed screw compressor can help you reduce costs, increase efficiency, and improve overall air compression performance. With so many benefits and options to choose from, there's no reason not to make the switch today.Get in touch with a reputable compressor supplier to learn more about the different variable speed screw compressor models available and find the perfect compressor that meets the demands of your operation.

Screw Air Compressor: Reliable Solution for Air Compression Needs in Ahmedabad, India

Title: A Comprehensive Guide to Two-Stage Screw CompressorsIntroduction:In the world of industrial machinery, air compressors hold immense value due to their role in numerous applications. One such type of air compressor gaining popularity is the two-stage screw compressor. In this blog, we will delve into the workings, benefits, and applications of two-stage screw compressors, shining a light on their contribution to the industrial sector.Chapter 1: Understanding Two-Stage Screw Compressors1.1 What is a Two-Stage Screw Compressor?1.2 How does a Two-Stage Screw Compressor Function?1.3 Key Components of a Two-Stage Screw Compressor1.4 Differentiating Two-Stage Screw Compressors from Other TypesChapter 2: Benefits of Two-Stage Screw Compressors2.1 Enhanced Efficiency and Energy Savings2.2 Reduced Maintenance Requirements2.3 Higher Pressure Ratios and Capacity2.4 Superior Cooling AbilitiesChapter 3: Applications of Two-Stage Screw Compressors3.1 Manufacturing and Industrial Processes3.2 Oil and Gas Industry3.3 Petrol Stations and Automotive Services3.4 Food and Beverage Industry3.5 Pharmaceutical and Medical ApplicationsChapter 4: Choosing the Right Two-Stage Screw Compressor4.1 Factors to Consider4.2 Capacity and Pressure Requirements4.3 Maintenance and Service4.4 Noise Levels4.5 Cost and Return on InvestmentChapter 5: Suggestions to Optimize Two-Stage Screw Compressor Performance5.1 Regular Maintenance and Inspection5.2 Monitoring System Parameters5.3 Proper Operating ConditionsChapter 6: Developing a Maintenance Schedule for Two-Stage Screw Compressors6.1 Routine Inspections and Lubrication6.2 Filter Replacement6.3 Cleaning and Oiling Air Intake Grills6.4 Implementing a Compressor Maintenance LogChapter 7: ConclusionIn this comprehensive guide, we have shed light on the incredible efficiency, benefits, and applications of two-stage screw compressors. These powerful machines have revolutionized various industries, ensuring uninterrupted operations, reducing energy costs, and enhancing productivity. By understanding the basics of these compressors and implementing proper maintenance practices, businesses can make the most of their investment.Remember, when choosing a two-stage screw compressor, it is essential to consider factors such as capacity requirements, maintenance needs, noise levels, and overall cost-effectiveness. Investing in a high-quality two-stage screw compressor will undoubtedly pave the way for enhanced efficiency and improved productivity.In conclusion, two-stage screw compressors have proven their worth in numerous industries and continue to play a crucial role in the success of businesses worldwide. Whether it is in manufacturing, oil and gas, automotive, or any other sector, these compressors are a reliable and efficient solution.By choosing the right two-stage screw compressor and implementing a comprehensive maintenance schedule, businesses can experience increased productivity, energy savings, and long-term cost benefits. The reliability and performance of two-stage screw compressors make them an indispensable asset for any industry needing a consistent supply of compressed air.If you are looking for a trusted supplier of high-quality two-stage screw compressors in Ahmedabad, India, we encourage you to explore the range of compressors available at Real Air Compressors. They have a proven track record of delivering reliable and efficient compressors to a diverse range of industries.Choose a two-stage screw compressor and embrace the benefits of unparalleled efficiency, performance, and productivity!(Keywords: two-stage screw compressor, screw air compressor, screw compressor, industrial compressor, air compressor, Ahmedabad, India, Real Air Compressors)

Ultimate Guide to the Power and Efficiency of 3 Phase Screw Compressors

XYZ Company Launches Innovative 3 Phase Screw Compressor for Improved Efficiency and Reliability[City], [Country] - XYZ Company, a leading provider of industrial air compressor solutions, has recently unveiled its latest innovation in the field of compressed air technology, the 3 Phase Screw Compressor. This cutting-edge compressor is designed to offer enhanced efficiency and reliability in various industrial applications.Compressed air is an essential utility in numerous industries, including manufacturing, automotive, construction, and pharmaceuticals. It is used for powering pneumatic tools, operating machinery, and even in spray painting applications. However, traditional compressors often face issues such as high energy consumption, maintenance requirements, and unstable air pressure. In response to these challenges, XYZ Company has developed the 3 Phase Screw Compressor, a game-changing solution that aims to address these pain points.The new 3 Phase Screw Compressor is built upon years of research, development, and expertise in the field of compressed air technology. It incorporates advanced features and technologies that set it apart from conventional compressors, providing customers with a more dependable and efficient solution.One of the key features of the 3 Phase Screw Compressor is its energy-saving capabilities. By utilizing advanced motor technology and intelligent control systems, the compressor minimizes energy consumption, resulting in significant cost savings for businesses. In addition, the compressor's high-efficiency cooling system ensures optimal performance while keeping operating costs low.Reliability is another paramount aspect of the 3 Phase Screw Compressor. The compressor is designed to deliver consistent and stable air pressure, vital for applications that require a reliable power source. XYZ Company has implemented state-of-the-art components and a robust build quality to ensure longevity and minimal downtime. With its low maintenance requirements, the 3 Phase Screw Compressor offers businesses increased productivity and reduced operational costs.Moreover, the 3 Phase Screw Compressor from XYZ Company is designed with user-friendly features, making it easy to operate and maintain. The intuitive control panel allows for effortless monitoring and adjustment of air pressure, ensuring optimal performance at all times. The compact design of the compressor also enables it to fit into tight spaces, reducing the need for extensive modifications to existing layouts.To ensure the highest quality and performance standards, XYZ Company subjects each 3 Phase Screw Compressor to rigorous testing and quality control procedures. The company's team of experts ensures that every unit delivers exceptional performance, reliability, and efficiency. Customers can therefore trust XYZ Company to provide them with a reliable and robust solution for their compressed air needs.Speaking about the launch of the 3 Phase Screw Compressor, [Name], the spokesperson for XYZ Company, said, "We are excited to introduce our latest innovation in compressed air technology, the 3 Phase Screw Compressor. This compressor embodies our commitment to delivering high-quality products that offer unmatched reliability and efficiency. We believe that this game-changing technology will revolutionize the way industries utilize compressed air, ultimately fostering improved productivity and profitability."XYZ Company is renowned for its dedication to innovation and delivering cutting-edge industrial air compressor solutions. With the launch of the 3 Phase Screw Compressor, the company continues to push the boundaries of compressed air technology, providing customers with products that meet their evolving needs and industry standards.In conclusion, XYZ Company's launch of the 3 Phase Screw Compressor represents a significant development in compressed air technology. The compressor's energy-saving features, reliability, and user-friendly design make it an ideal choice for industries seeking optimal performance and efficiency. With this innovative solution, XYZ Company reaffirms its position as a leader in providing high-quality compressed air solutions.

Vertical Air Compressor for Oil-Free Operations: Latest News

[Introduction]In the ever-evolving world of industrial equipment, innovation plays a crucial role in meeting the needs of various industries. One such innovation is the development of oil-free vertical air compressors, which have revolutionized the compressor industry by providing cleaner and more efficient air compression solutions. (Brand name removed), a renowned name in the industrial equipment market, has taken a significant step forward with their latest oil-free vertical air compressor.[Company Introduction]Founded in (year), (Company name) has established itself as a global leader in providing cutting-edge industrial equipment and solutions. With a commitment to innovation, quality, and customer satisfaction, the company has earned a reputation for delivering products that exceed industry standards. (Brand name) has an extensive range of products, including air compressors, generators, pumps, and more, catering to the diverse needs of industries such as manufacturing, construction, healthcare, and energy.The company's state-of-the-art facilities and advanced manufacturing technologies enable them to develop world-class products. Their team of experienced engineers and technicians work tirelessly to design, test, and manufacture equipment that meets the ever-changing demands of modern industries. With a focus on sustainability, (Company name) ensures that their products have minimal environmental impact while maximizing efficiency.[Oil-Free Vertical Air Compressor]Recognizing the growing need for cleaner air compression solutions, (Company name) has launched its latest oil-free vertical air compressor. This compressor is designed to provide businesses with a reliable and efficient solution that eliminates concerns related to oil contamination.Oil contamination has long been a challenge for industries that require compressed air, as even a tiny amount of oil can negatively impact the performance and longevity of the equipment using it. Traditional compressors, although widely used, often introduce oil into the compressed air, leading to costly maintenance and potential risks to the end-products or processes.The new oil-free vertical air compressor from (Company name) overcomes these challenges by ensuring 100% oil-free compressed air. This eliminates the risk of oil contamination, allowing businesses to operate with peace of mind knowing that their applications and products are not compromised.The key features of the oil-free vertical air compressor include:1. Advanced Technology: The compressor is equipped with state-of-the-art technology that ensures efficient and reliable operation. The cutting-edge design and precision-engineered components minimize energy consumption, resulting in significant cost savings for businesses.2. Vertical Configuration: The vertical configuration of the compressor optimizes floor space utilization, making it ideal for industries with limited space. The compact design and vertical arrangement also simplify installation and maintenance processes.3. Enhanced Performance: The oil-free vertical air compressor delivers consistent performance, ensuring a steady supply of clean compressed air. This is essential for industries requiring high-quality air, such as pharmaceuticals, electronics, food processing, and more.4. Low Maintenance: The elimination of oil in the compression process reduces wear and tear on components, resulting in reduced maintenance requirements and extended equipment lifespan. This translates into cost savings for businesses.5. Environmentally Friendly: The absence of oil in the compressed air not only benefits the end-products or processes but also contributes to a cleaner and healthier environment. Reduced oil consumption leads to lower carbon emissions, supporting sustainability initiatives.(Company name)'s commitment to customer satisfaction is reflected in the warranty and after-sales service provided with their oil-free vertical air compressor. Their dedicated support team ensures prompt assistance in case of any issues or inquiries, ensuring minimal downtime for businesses.[Conclusion]The introduction of (brand name removed)'s oil-free vertical air compressor marks a significant advancement in the field of air compression technology. Solving the long-standing challenge of oil contamination, this compressor offers businesses a reliable, efficient, and environmentally friendly solution. With their unwavering commitment to innovation and customer satisfaction, (Company name) continues to push the boundaries of industrial equipment, empowering businesses across various industries to achieve optimal performance and productivity.