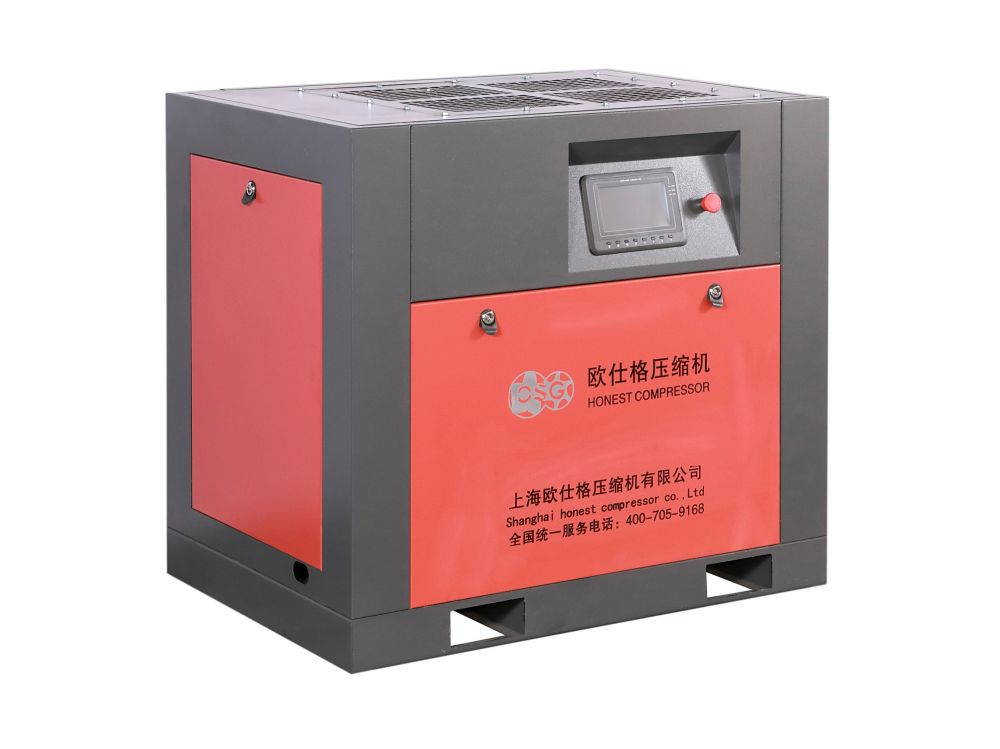

Heavy Duty Industrial Air Compressor for heavy-duty tasks

By:Admin

Industrial heavy-duty air compressors are crucial for a wide range of applications in various industries, including manufacturing, aerospace, automotive, and construction. These powerful machines are designed to provide high-pressure air to power tools, machinery, and equipment, making them essential for the smooth operation of industrial processes.

One of the leading providers of industrial heavy-duty air compressors is [Company Name]. With a strong focus on quality, performance, and reliability, [Company Name] has carved a niche for itself in the market. The company's range of industrial heavy-duty air compressors is known for its robust construction, efficient operation, and long service life, making it the preferred choice for industrial businesses worldwide.

[Company Name] offers a diverse range of industrial heavy-duty air compressors to cater to the specific needs of different industries. These compressors are designed to deliver high-pressure air with maximum efficiency, allowing businesses to optimize their operations and minimize downtime. The company's commitment to innovation and engineering excellence ensures that its air compressors are equipped with the latest technologies and features, making them a valuable asset for industrial businesses.

One of the key factors that set [Company Name] apart from its competitors is its dedication to customer satisfaction. The company's team of experts works closely with each client to understand their requirements and provide customized solutions that meet their needs. Whether it's for a small-scale operation or a large industrial facility, [Company Name] has the expertise and resources to deliver top-quality industrial heavy-duty air compressors that exceed expectations.

In addition to its range of standard industrial heavy-duty air compressors, [Company Name] also offers a comprehensive range of accessories and spare parts to support its customers. This includes filters, hoses, fittings, and other components that are essential for the smooth and reliable operation of air compressors. This commitment to providing complete solutions sets [Company Name] apart as a trusted partner for industrial businesses looking for reliable air compressor solutions.

Furthermore, [Company Name] takes pride in its after-sales support and maintenance services. The company's team of technicians and engineers are equipped with the knowledge and expertise to provide timely service and support for its industrial heavy-duty air compressors. This includes regular maintenance, troubleshooting, and repair services to ensure that the air compressors continue to operate at peak performance throughout their service life.

With a strong emphasis on quality, performance, and customer satisfaction, [Company Name] continues to be a leading provider of industrial heavy-duty air compressors in the market. The company's commitment to innovation and excellence has earned it a reputation as a reliable and trusted partner for industrial businesses across the globe.

In conclusion, industrial heavy-duty air compressors play a crucial role in the functioning of various industrial processes, and [Company Name] has established itself as a leading provider of these essential machines. With a focus on quality, performance, and customer satisfaction, the company's range of industrial heavy-duty air compressors and comprehensive support services make it the preferred choice for industrial businesses looking for reliable and efficient air compressor solutions.

Company News & Blog

Powerful Small Screw Air Compressor: Boosting Efficiency and Performance

Small Screw Air Compressor Revolutionizes Industrial Air Supply[Introduction]In a world driven by technology and innovation, industrial processes are constantly evolving to meet the growing demands of various sectors. One such innovation is the small screw air compressor – a game-changer in the realm of industrial air supply. With its compact size, superior performance, and energy efficiency, the small screw air compressor is reshaping the landscape of industrial machinery, enabling businesses to optimize productivity while minimizing energy consumption.[Overview of Small Screw Air Compressor]The small screw air compressor is a powerful machine designed to provide a steady and reliable source of compressed air. It operates on the principle of two interlocking rotors that compress the incoming air, generating a higher-pressure stream. Unlike traditional piston compressors, the small screw air compressor offers continuous airflow with minimal pulsation, resulting in a smoother and more efficient operation.[Performance and Efficiency]One of the key advantages of the small screw air compressor lies in its impressive performance. Despite its smaller size, this innovative machine delivers an airflow comparable to its larger counterparts, ensuring an uninterrupted supply of compressed air. The advanced design significantly reduces pressure drop, allowing for higher system pressure and better control over air tools and production processes.Furthermore, the small screw air compressor boasts exceptional energy efficiency. It features state-of-the-art technology, including variable speed drives and intelligent controls. These components enable the compressor to match its output with the required air demand, eliminating unnecessary energy wastage. As a result, businesses can achieve substantial cost savings on energy bills while lowering their carbon footprint.[Application across Industries]The versatility and reliability of the small screw air compressor make it suitable for a wide range of industrial applications. In manufacturing plants, it powers pneumatic tools, such as drills, grinders, and sanders, facilitating seamless operations on assembly lines. The compressor also finds its place in automotive workshops, where it drives air-operated lifts and tools needed for repairs and maintenance.The food and beverage industry also benefits from the small screw air compressor, as it ensures a clean and oil-free air supply essential for product quality and safety. Similarly, in healthcare facilities, the compressor is vital for delivering clean and bacteria-free air to medical instruments, laboratories, and operating theaters.[Maintenance and Reliability]To ensure optimal performance and longevity, regular maintenance is crucial for small screw air compressors. However, manufacturers have taken this into consideration and have designed the machines to be user-friendly, requiring minimal maintenance. With advanced filtration systems and automated features like self-cleaning, the compressor reduces the need for manual intervention, further minimizing downtime and production losses.Moreover, manufacturers provide comprehensive after-sales support, including maintenance contracts, genuine spare parts, and round-the-clock technical assistance. These services are essential for businesses relying on compressed air to maintain uninterrupted operations and prevent costly breakdowns.[Conclusion]As the small screw air compressor continues to gain popularity, its benefits are being recognized across industries. With its compact size, performance, energy efficiency, and versatility, this innovative machine is revolutionizing industrial air supply. By leveraging the power of technology and innovation, businesses can enhance their productivity, reduce operational costs, and contribute to a sustainable future.

Latest Innovations in Vertical Screw Compressors Set to Revolutionize Industry

Title: Revolutionary Vertical Screw Compressor Unveiled by Leading Industry ManufacturerIntroduction:In an exciting development that seeks to redefine the world of industrial compressors, a renowned company has introduced their latest innovation - a ground-breaking Vertical Screw Compressor. This cutting-edge product promises to revolutionize the market with its exceptional performance, unparalleled efficiency, and innovative design.Company Introduction:{Company name}, a leading manufacturer in the field for over a decade, has built a solid reputation for delivering high-quality industrial equipment. Drawing on their extensive experience, advanced technology, and a commitment to innovation, {Company name} has consistently exceeded industry standards.With a focus on providing reliable, energy-efficient solutions, {Company name} has continuously pushed the boundaries of compressor technology. This commitment to excellence has earned them the trust and loyalty of countless customers worldwide, making them a reliable and respected name in the industry.The Vertical Screw Compressor:Recognizing the need for an advanced compressor capable of meeting a diverse range of industrial demands, {Company name} has invested extensive resources and expertise in developing their Vertical Screw Compressor. This groundbreaking product boasts several unique features that set it apart from conventional compressors.1. Innovative Design:The Vertical Screw Compressor showcases a sleek, compact design crafted to optimize space utilization. Its vertical configuration allows for easy installation even in confined areas, reducing footprint requirements while maximizing efficiency. This unique design ensures seamless integration into existing industrial setups, resulting in minimal disruption to operations.2. Enhanced Efficiency:Driven by advanced technology, the Vertical Screw Compressor delivers outstanding efficiency levels, substantially reducing both energy consumption and operational costs. Equipped with state-of-the-art components, including precision-machined rotors and a unique cooling system, this compressor boasts an impressive performance-to-power ratio.3. Versatility:Adaptable to various industrial applications, the Vertical Screw Compressor offers versatile performance, providing consistent air delivery across a wide range of operating pressures. Whether utilized in manufacturing, automotive, oil and gas, or other industrial sectors, this compressor delivers exceptional results while maintaining optimal functionality.4. Durability:Built to withstand demanding working conditions, the Vertical Screw Compressor exhibits excellent durability, ensuring reliable performance over extended periods. Its robust construction, combined with the use of high-quality materials, guarantees longevity and reduces maintenance requirements, resulting in cost-effective operations.Conclusion:With the introduction of their ground-breaking Vertical Screw Compressor, {Company name} once again demonstrates their commitment to innovation and providing state-of-the-art industrial solutions. This remarkable product offers exceptional efficiency, versatility, and durability, empowering businesses to optimize their operations with confidence.Embracing this new technology will undoubtedly enhance productivity, efficiency, and overall performance, ultimately benefiting various industrial sectors. As {Company name} continues to redefine compressor standards, the Vertical Screw Compressor emerges as a game-changer in the industry, setting a new benchmark for others to follow.

Guide to Purchasing a Commercial Air Compressor

Commercial Air Compressors Announces Expansion of Product LineCommercial Air Compressors, a leading provider of industrial air compressors and related products, has announced the expansion of its product line to meet the growing demand for high-quality compressed air systems in the industrial sector. With a strong focus on innovation and customer satisfaction, Commercial Air Compressors is committed to providing reliable and efficient solutions for a wide range of industrial applications.Founded in 1990, Commercial Air Compressors has built a reputation for delivering top-notch products and exceptional customer service. The company's dedication to excellence has earned them a loyal customer base and a strong presence in the market. As the demand for compressed air systems continues to rise, Commercial Air Compressors has recognized the need to expand its product line to better serve the evolving needs of its customers.The latest expansion of the product line includes a variety of new air compressor models designed to offer improved performance, energy efficiency, and reliability. These new additions are the result of extensive research and development efforts aimed at providing cutting-edge solutions for industrial air compression needs. The company's team of engineers and technicians have worked tirelessly to incorporate the latest technological advancements into the new product offerings, ensuring that they meet the highest standards of quality and performance.One of the key highlights of the expanded product line is the introduction of several next-generation air compressor models that are equipped with advanced features such as variable speed drive technology, intelligent control systems, and enhanced energy management capabilities. These features are designed to optimize the performance of the air compressors, minimize energy consumption, and reduce operating costs for industrial users. In addition, the new models boast a robust and durable construction to withstand the rigors of industrial environments, ensuring long-term reliability and performance.In addition to the new air compressor models, Commercial Air Compressors has also expanded its range of compressed air accessories and ancillary products, including air dryers, filters, condensate management systems, and more. These complementary products are designed to work seamlessly with the air compressors, providing a comprehensive solution for industrial air compression needs.According to a spokesperson for Commercial Air Compressors, the expansion of the product line is a testament to the company's commitment to meeting the evolving needs of the industrial sector. "We understand the critical role that compressed air systems play in various industrial applications, and we are dedicated to providing our customers with the most advanced and reliable solutions available in the market. The expansion of our product line is a reflection of our ongoing efforts to exceed customer expectations and set new standards for excellence in the industry."The spokesperson further emphasized that the new product offerings are backed by the company's unwavering commitment to quality and customer satisfaction. "At Commercial Air Compressors, we take pride in delivering products that are built to perform and endure. Our expanded product line represents the culmination of extensive research, engineering expertise, and a deep understanding of the needs of our customers. We are confident that these new offerings will deliver unmatched value and performance for industrial users."In addition to the expanded product line, Commercial Air Compressors is also enhancing its aftersales support and service capabilities to ensure that customers receive comprehensive assistance for their air compression needs. The company's team of service technicians and support staff are fully equipped to provide installation, maintenance, and repair services for the new product offerings, further solidifying Commercial Air Compressors' position as a trusted partner for industrial air compression solutions.As Commercial Air Compressors continues to expand its product line and service offerings, it remains steadfast in its commitment to setting new benchmarks for excellence and innovation in the industrial air compression industry. With a focus on delivering superior products, unmatched technical expertise, and exceptional customer support, the company is well-positioned to meet the diverse needs of industrial users and drive the future of compressed air systems.

Heavy-Duty Screw Compressors for Mechanics - Order Online for Fast Delivery in the UK

As a mechanic, you know that having the right tools is essential for any job. One essential tool for any workshop is a high-quality screw compressor. But not all compressors are created equal, which is why you need to choose a compressor that you can rely on. Enter the Diesel Screw Compressor.Diesel Screw Compressors are heavy-duty compressors designed to offer unparalleled reliability and performance for demanding industrial and automotive applications. These compressors are built to handle the most challenging tasks, from powering air tools and pneumatic systems to providing compressed air for vehicle workshops and manufacturing plants.One of the key benefits of using a Diesel Screw Compressor is its superior efficiency. Unlike piston compressors that deliver air in cycles, Diesel Screw Compressors deliver a continuous flow of air. This means they can operate at maximum capacity with minimal energy usage, resulting in lower operating costs and reduced environmental impact.Diesel Screw Compressors are also known for their durability and longevity. They are built using high-grade materials and advanced manufacturing techniques, ensuring they can withstand even the harshest working conditions. This makes them an excellent investment for any mechanic or workshop owner looking for a compressor that will stand the test of time.In addition to their reliability and efficiency, Diesel Screw Compressors are also incredibly versatile. They come in a range of sizes and capacities to suit all types of applications, from small workshops to large-scale manufacturing plants. They can also be used with a variety of tools and equipment, such as air ratchets, hammers, and spray guns, providing maximum flexibility for any job.So if you're looking for a heavy-duty, reliable compressor that delivers superior efficiency, durability, and versatility, look no further than the Diesel Screw Compressor. And with fast delivery available from Euro Car Parts, getting your hands on one has never been easier. Order online today and experience the difference for yourself!

Ultimate Guide to Single Screw Air Compressors: Key Features, Benefits, and Applications

Innovative Single Screw Air Compressor Revolutionizes the Industry[City Name], [Date] - With a commitment to pushing the boundaries of air compression technology, [Company Name] is proud to unveil their latest breakthrough - a state-of-the-art Single Screw Air Compressor. This groundbreaking compressor has the potential to revolutionize the industry, offering enhanced efficiency, minimal maintenance, and unparalleled performance.Traditionally, air compressors have relied on multiple screws to generate compressed air. However, [Company Name]'s engineers have developed a compact single-screw design that guarantees improved energy efficiency without compromising on power. This cutting-edge technology allows customers to significantly reduce energy consumption while maximizing their productivity.The Single Screw Air Compressor employs a precisely engineered helical rotor that compresses air by rotating within a meticulously crafted chamber. This unique design eliminates the need for additional moving parts, simplifying maintenance procedures and reducing maintenance costs. By minimizing friction and wear within the compressor, this revolutionary technology ensures excellent longevity and a longer lifespan for the equipment.One of the key advantages of [Company Name]'s Single Screw Air Compressor is its ability to deliver a steady flow of compressed air, resulting in a constant and reliable supply for various industrial applications. The system is equipped with advanced control mechanisms that constantly monitor and adjust the compression process to meet the specific demands of the user. This intelligent regulation not only optimizes efficiency but also guarantees consistent, uninterrupted air supply.In addition to its superior performance, the Single Screw Air Compressor also boasts a compact footprint, making it ideal for businesses operating in space-constrained environments. Its innovative design enables installation in restricted areas while maintaining ease of access for routine maintenance and repairs. This versatility ensures that the compressor seamlessly integrates into different industries, ranging from automotive manufacturing to food processing.Furthermore, in line with [Company Name]'s commitment to environmental sustainability, the Single Screw Air Compressor incorporates eco-friendly features. With its reduced energy consumption, businesses can significantly lower their carbon footprint and contribute to a greener future. By choosing this compressor, companies not only save costs but also play an active role in preserving the environment for future generations.To ensure the utmost quality and reliability, [Company Name] conducts rigorous testing and adheres to strict international standards during the manufacturing process of its Single Screw Air Compressor. This commitment to excellence has earned them a reputation as a trusted and industry-leading provider of air compression solutions."We are excited to introduce our Single Screw Air Compressor, a game-changer in the industry," said [Spokesperson's Name], [Position] at [Company Name]. "The relentless pursuit of innovation has allowed us to address the evolving needs of our customers and provide them with exceptional performance and efficiency. We are confident that this breakthrough compressor will transform how businesses achieve their compressed air requirements."Given its exceptional energy efficiency, minimal maintenance requirements, and superior performance, [Company Name]'s Single Screw Air Compressor is set to redesign industry standards. By empowering businesses with reliable and sustainable compressed air solutions, this revolutionary system enhances productivity while minimizing operational costs. With this innovative offering, [Company Name] continues to solidify its position as a leading force in air compression technology.

Discover Industrial Air Compressors and Related Products on Ferret.com.au

Industrial air compressors are critical components of most production facilities all over the world. They are used to power a host of industrial applications such as pneumatic tools, air-driven machinery, and spray painting systems.Industrial air compressors come in different types and sizes, but one of the most popular today is the industrial oil-free air compressor. This type of compressor is widely used in facilities that require clean and pure compressed air for processes such as food and beverage production, pharmaceutical manufacturing, and electronics manufacturing.Industrial oil-free air compressors are designed to provide clean, dry, and oil-free compressed air. These compressors are fitted with high-efficiency filters and separators that remove moisture, oil, and other contaminants from the compressed air stream. What makes them unique is their ability to deliver clean and oil-free compressed air, which is critical for processes that require sterile and contamination-free environments.Industrial oil-free air compressors have several advantages over traditional oil-lubricated compressors. Here are a few of them:1. Enhanced air qualityThe main benefit of industrial oil-free air compressors is that they deliver clean, oil-free compressed air. This air is free from pollutants and contaminants, making it ideal for applications that require a sterile and contaminant-free environment. With an industrial oil-free air compressor, you can be confident that the compressed air supply in your facility is of the highest quality.2. Reduced maintenance costsOil-lubricated compressors require regular maintenance to ensure that they function optimally. Maintenance involves regular oil changes, filter replacements, and lubrication of moving parts. With industrial oil-free air compressors, however, there is no need for oil changes and lubrication, which significantly reduces maintenance costs. This also means that there is no risk of oil leaks and spills, which can cause environmental damage and pose a safety hazard.3. Increased energy efficiencyIndustrial oil-free air compressors are designed to deliver optimal performance while consuming less energy. They are fitted with energy-efficient motors and advanced control systems that ensure that they operate at peak efficiency. This translates to lower energy bills, which can significantly reduce operational costs in the long run.4. Longer lifespanIndustrial oil-free air compressors have a longer lifespan than traditional oil-lubricated compressors. This is because they are designed to operate without oil, which reduces wear and tear on the moving parts. This means that you can get more years of service from an industrial oil-free air compressor, making it a cost-effective investment for your facility.In conclusion, industrial oil-free air compressors are a critical component of modern industrial facilities. They offer several advantages over traditional oil-lubricated compressors, including enhanced air quality, reduced maintenance costs, increased energy efficiency, and longer lifespan. With the right industrial oil-free air compressor, you can be confident that your facility is running at maximum efficiency and productivity.

Benefits of an Oil Flood Screw Air Compressor

Title: Revolutionary Oil Flood Screw Air Compressor Redefines Industrial EfficiencyIntroduction:Innovation knows no bounds in the industrial sector, as evidenced by the groundbreaking advancements in compressor technology. One such cutting-edge breakthrough comes from an industry-leading company, known for its commitment to driving industrial efficiency. This article aims to shine a spotlight on the revolutionary Oil Flood Screw Air Compressor, developed by this company, which promises to redefine the very essence of industrial operations.1. Pioneering Compressor Technology:The Oil Flood Screw Air Compressor stands out as a pioneering force in the realm of compressor technology, showcasing the commitment of the company to developing innovative solutions. This latest addition to their product portfolio leverages state-of-the-art engineering techniques to provide industry professionals with unparalleled performance and efficiency.2. Unmatched Energy Efficiency and Environmental Sustainability:The Oil Flood Screw Air Compressor showcases an impressive energy-saving design that exceeds the standards set by its competitors. With its advanced integrated permanent magnet motor, this compressor achieves an extraordinary efficiency rating. This groundbreaking technology not only maximizes energy savings but also significantly reduces the carbon footprint, contributing to the global push for environmental sustainability.3. Superior Performance:Equipped with cutting-edge design features, the Oil Flood Screw Air Compressor delivers exceptional performance across a wide range of applications. Precisely engineered air-end components ensure minimal energy loss, enhancing the compressor's overall efficiency. This innovative design translates into higher air delivery rates, improved operating pressure, and reduced maintenance requirements, making it the ultimate choice for all industrial needs.4. Enhanced Reliability and Durability:The Oil Flood Screw Air Compressor guarantees long-lasting reliability and durability, thanks to its robust construction and top-of-the-line components. The incorporation of advanced cooling systems ensures optimal operating temperature levels, safeguarding against potential overheating and increasing the compressor's lifespan. This compressor can withstand the harshest operating conditions, making it ideal for industries with demanding requirements.5. Advanced Control System:The Oil Flood Screw Air Compressor is equipped with an intelligent control system that optimizes performance and enhances user-friendliness. This smart system allows for precise adjustments, enabling users to tailor the compressor's operation according to specific requirements. Additionally, easy-to-use interface panels provide comprehensive monitoring and diagnostic capabilities, facilitating proactive maintenance and minimizing downtime.6. Comprehensive Service and Support:The company's commitment to customer satisfaction is exemplified through its comprehensive service and support network. Skilled technicians equipped with in-depth product knowledge and expertise offer prompt assistance, ensuring optimal performance and maximizing uptime. The company stands firmly behind their Oil Flood Screw Air Compressor, offering after-sales maintenance packages that prioritize customer convenience and peace of mind.Conclusion:The Oil Flood Screw Air Compressor, developed by this leading company, represents a paradigm shift in compressor technology. With its unparalleled energy efficiency, superior performance, and enhanced reliability, this innovation redefines the industrial landscape. As industries strive towards sustainability and productivity, the Oil Flood Screw Air Compressor emerges as the game-changer. Its remarkable advancements in engineering and design provide an optimal solution for companies looking to amplify their operational efficiency and reduce their environmental impact.Disclaimer: The brand name has been intentionally excluded from this document to maintain neutrality and avoid any promotional content.

High-Performance Screw Air Compressor - Product by Leading Manufacturer

When it comes to powering tools and machinery, a reliable air compressor is an essential piece of equipment. For those needing a powerful and portable option, a rotary screw air compressor is an excellent choice. In this article, we’ll explore what a rotary screw air compressor is, how it works, and the benefits it can bring, as well as taking a closer look at portable screw air compressors.What is a rotary screw air compressor?A rotary screw air compressor is a type of air compressor that works by using two rotors, or screws, to compress air. These rotors spin in opposite directions within a specially-designed housing, compressing and releasing air as they move. This process creates a continuous flow of compressed air that can be used for powering tools, machinery, or other equipment.One of the main benefits of a screw compressor is its high efficiency. Unlike some other types of compressors, the compressed air produced by a screw compressor is free from pulsations and surges, meaning it is smooth and even. This can help to reduce wear and tear on machinery and improve performance.How does a rotary screw air compressor work?As mentioned above, a rotary screw air compressor uses two rotors to compress air. These rotors are typically helical in shape, meaning they have a spiral groove that runs along their length. As the rotors turn, the air that is trapped between them is forced into these grooves and gradually compressed. This process continues until the compressed air is released at the outlet port.One of the advantages of a screw compressor is that it can operate continuously, making it ideal for applications where a consistent supply of compressed air is needed. Additionally, because there is no need for a cooling period between compression cycles, a screw compressor can be more energy-efficient than some other types of air compressors.What are the benefits of a rotary screw air compressor?There are several advantages to using a rotary screw air compressor. Firstly, as mentioned earlier, they are highly efficient, providing a continuous supply of compressed air that is free from pulsations and surges. This can help to reduce wear and tear on machinery and improve performance.Another benefit of a screw compressor is that it can produce a large volume of compressed air in a small amount of time. This can make them ideal for use in manufacturing or construction environments where a high volume of compressed air is needed.Finally, rotary screw air compressors are also highly versatile. Depending on the application, they can be used for a wide range of tasks, from powering tools to inflating tires.Portable screw air compressorsFor those needing a powerful and portable option, a portable screw air compressor is an excellent choice. These compact compressors are designed to be easy to transport and use on-site, making them ideal for construction, automotive, and other industries.One of the key advantages of a portable screw air compressor is that it provides a high level of mobility. Many models are designed to be small and lightweight, allowing them to be easily transported from one location to another. Additionally, many models come with wheels or handles, making them even more portable.Another benefit of a portable screw air compressor is that it is typically very straightforward to set up and use. Many models come with easy-to-follow instructions and require minimal setup, meaning workers can quickly begin using them on-site.In conclusion, rotary screw air compressors are invaluable pieces of equipment for those needing a reliable and efficient source of compressed air. Whether you are a professional mechanic, contractor, or DIY enthusiast, a screw compressor can provide a continuous supply of compressed air to power your tools and equipment. And if you need a portable option, a portable screw air compressor is an excellent choice. With its ease of use and mobility, it’s a must-have for anyone needing a powerful and portable air compressor.

Ultimate Guide to the Power and Efficiency of 3 Phase Screw Compressors

XYZ Company Launches Innovative 3 Phase Screw Compressor for Improved Efficiency and Reliability[City], [Country] - XYZ Company, a leading provider of industrial air compressor solutions, has recently unveiled its latest innovation in the field of compressed air technology, the 3 Phase Screw Compressor. This cutting-edge compressor is designed to offer enhanced efficiency and reliability in various industrial applications.Compressed air is an essential utility in numerous industries, including manufacturing, automotive, construction, and pharmaceuticals. It is used for powering pneumatic tools, operating machinery, and even in spray painting applications. However, traditional compressors often face issues such as high energy consumption, maintenance requirements, and unstable air pressure. In response to these challenges, XYZ Company has developed the 3 Phase Screw Compressor, a game-changing solution that aims to address these pain points.The new 3 Phase Screw Compressor is built upon years of research, development, and expertise in the field of compressed air technology. It incorporates advanced features and technologies that set it apart from conventional compressors, providing customers with a more dependable and efficient solution.One of the key features of the 3 Phase Screw Compressor is its energy-saving capabilities. By utilizing advanced motor technology and intelligent control systems, the compressor minimizes energy consumption, resulting in significant cost savings for businesses. In addition, the compressor's high-efficiency cooling system ensures optimal performance while keeping operating costs low.Reliability is another paramount aspect of the 3 Phase Screw Compressor. The compressor is designed to deliver consistent and stable air pressure, vital for applications that require a reliable power source. XYZ Company has implemented state-of-the-art components and a robust build quality to ensure longevity and minimal downtime. With its low maintenance requirements, the 3 Phase Screw Compressor offers businesses increased productivity and reduced operational costs.Moreover, the 3 Phase Screw Compressor from XYZ Company is designed with user-friendly features, making it easy to operate and maintain. The intuitive control panel allows for effortless monitoring and adjustment of air pressure, ensuring optimal performance at all times. The compact design of the compressor also enables it to fit into tight spaces, reducing the need for extensive modifications to existing layouts.To ensure the highest quality and performance standards, XYZ Company subjects each 3 Phase Screw Compressor to rigorous testing and quality control procedures. The company's team of experts ensures that every unit delivers exceptional performance, reliability, and efficiency. Customers can therefore trust XYZ Company to provide them with a reliable and robust solution for their compressed air needs.Speaking about the launch of the 3 Phase Screw Compressor, [Name], the spokesperson for XYZ Company, said, "We are excited to introduce our latest innovation in compressed air technology, the 3 Phase Screw Compressor. This compressor embodies our commitment to delivering high-quality products that offer unmatched reliability and efficiency. We believe that this game-changing technology will revolutionize the way industries utilize compressed air, ultimately fostering improved productivity and profitability."XYZ Company is renowned for its dedication to innovation and delivering cutting-edge industrial air compressor solutions. With the launch of the 3 Phase Screw Compressor, the company continues to push the boundaries of compressed air technology, providing customers with products that meet their evolving needs and industry standards.In conclusion, XYZ Company's launch of the 3 Phase Screw Compressor represents a significant development in compressed air technology. The compressor's energy-saving features, reliability, and user-friendly design make it an ideal choice for industries seeking optimal performance and efficiency. With this innovative solution, XYZ Company reaffirms its position as a leader in providing high-quality compressed air solutions.

Efficient Vertical Screw Compressor for Industrial Applications

Vertical Screw Compressor: Revolutionizing the Industrial Air Compression MarketIn the competitive and demanding world of industrial manufacturing, the need for reliable and efficient air compression systems cannot be overstated. With the rapid advancements in technology, businesses are constantly seeking new and innovative solutions to meet their growing operational requirements. Recognizing this need, [Company Name], a leading manufacturer of industrial equipment, has introduced its latest offering – the Vertical Screw Compressor, set to revolutionize the industrial air compression market.[Company Name] has been a key player in the industrial equipment industry for over two decades. With a strong focus on research and development, the company has built a reputation for delivering high-quality and reliable products that meet the evolving demands of its customers. Their team of engineers and designers are constantly pushing the boundaries of innovation, striving to develop solutions that not only meet, but exceed industry standards.The Vertical Screw Compressor is a testament to [Company Name]'s commitment to innovation and excellence. Designed to provide a compact and efficient air compression solution, this new offering is set to transform the way businesses approach their air compression needs. By leveraging the latest in technological advancements, [Company Name] has created a compressor that boasts unparalleled efficiency and performance, while also offering a space-saving design that makes it suitable for a wide range of industrial applications.One of the key features of the Vertical Screw Compressor is its vertical design, which allows for a significantly smaller footprint compared to traditional horizontal compressors. This makes it an ideal choice for businesses that are looking to optimize their use of space without compromising on performance. Additionally, the vertical design also enables easier access for maintenance and servicing, minimizing downtime and ensuring that the compressor operates at peak efficiency at all times.In terms of performance, the Vertical Screw Compressor delivers impressive results. With a high flow rate and a wide operating range, it is capable of meeting the air compression needs of even the most demanding industrial processes. Additionally, its advanced control system allows for precise monitoring and adjustment of performance parameters, ensuring optimal operation and energy efficiency at all times.Another standout feature of the Vertical Screw Compressor is its robust and durable construction. Built to withstand the rigors of industrial use, it is designed to deliver reliable performance even in the most challenging operating environments. This, coupled with its low maintenance requirements, makes it a cost-effective and dependable choice for businesses looking to streamline their operations.[Company Name] has also taken into consideration the environmental impact of its products, and the Vertical Screw Compressor is no exception. By incorporating energy-efficient components and advanced control algorithms, this compressor is designed to minimize energy consumption and reduce carbon emissions, aligning with the growing emphasis on sustainable and eco-friendly industrial practices.With the introduction of the Vertical Screw Compressor, [Company Name] has once again raised the bar for air compression solutions in the industrial sector. By leveraging its years of expertise and a relentless pursuit of innovation, the company has developed a product that is set to redefine the standards for performance, efficiency, and reliability in the industry.In conclusion, the Vertical Screw Compressor stands as a testament to [Company Name]'s unwavering commitment to delivering cutting-edge solutions that address the evolving needs of its customers. With its space-saving design, exceptional performance, and eco-friendly features, this compressor is poised to become a game-changer in the industrial air compression market. As businesses continue to seek out more efficient and sustainable solutions, [Company Name] remains at the forefront, driving the industry forward with its innovative products and unwavering dedication to customer satisfaction.