Product Description

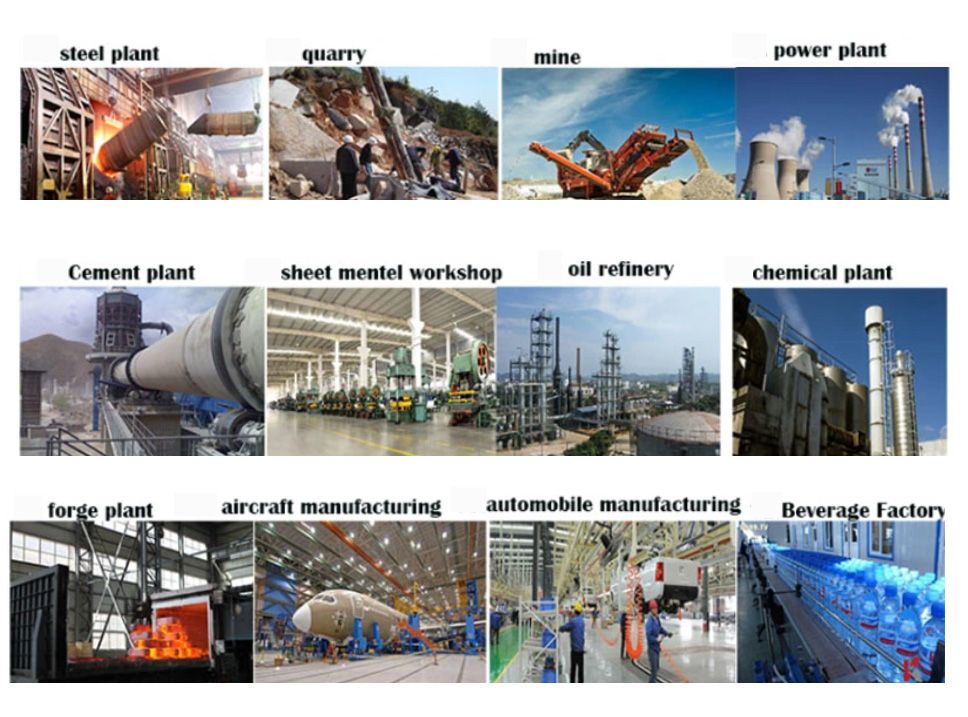

The two-stage compression oil injection screw air compressor has a reasonable equal pressure ratio, ultra-small leakage, and ultra-low noise host design. It combines the first-stage compression rotor and the second-stage compression rotor in one casing, and directly drives them respectively through the front gear, so that each stage of the rotor can obtain the best line speed matching the gas production during operation, and at the same time, the reasonable compression The ratio can effectively reduce the compression leakage. Therefore, the compression efficiency is much higher than that of single-stage compression. Therefore, compared with single-stage compression, two-stage compression is more energy-efficient. With the same power, it can have 12%-18% more displacement than single-compression compressors. Compared with single-stage compression, two-stage compression saves 15% power. The force on the rotor and bearing is small, and the diameter of the rotor is large and the speed is low. , so the operation is more reliable.Application fields

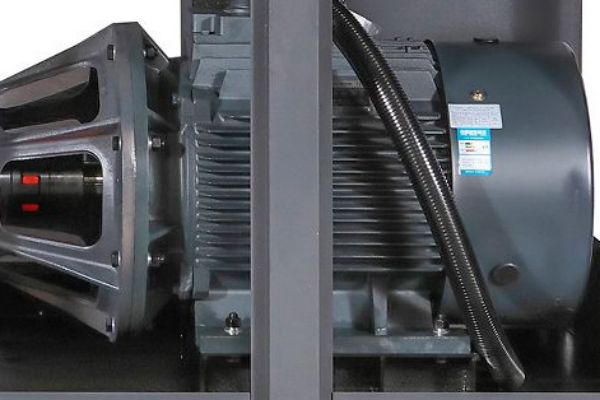

High-efficiency Motor Feature: IE4 permanent magnet motor/IE4 High-efficiency motor Advantage: Motor efficiency 97% Benefit: 5% energy-saving

Intelligent Control Feature: VFD system Advantage: Constant pressure output to remove pressure fluctuation and off-load, Constant temperature output at 9-~85°C, Low starting current to protect components Benefit: 15% energy-saving

Intelligent Control Feature: VFD system Advantage: Constant pressure output to remove pressure fluctuation and off-load, Constant temperature output at 9-~85°C, Low starting current to protect components Benefit: 15% energy-saving

Product Features

Two stage air end Feature: Two-stage compressor air-end Advantage: Low compression ratio, Low temperature rising, Low air leakage Benefit: 15% energy-saving

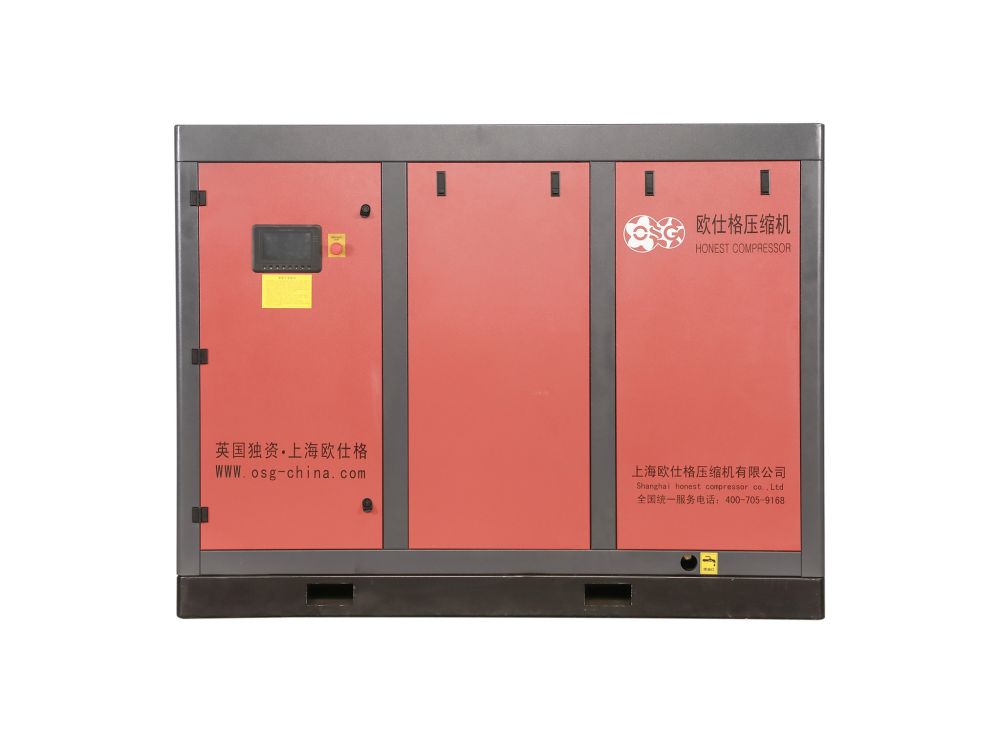

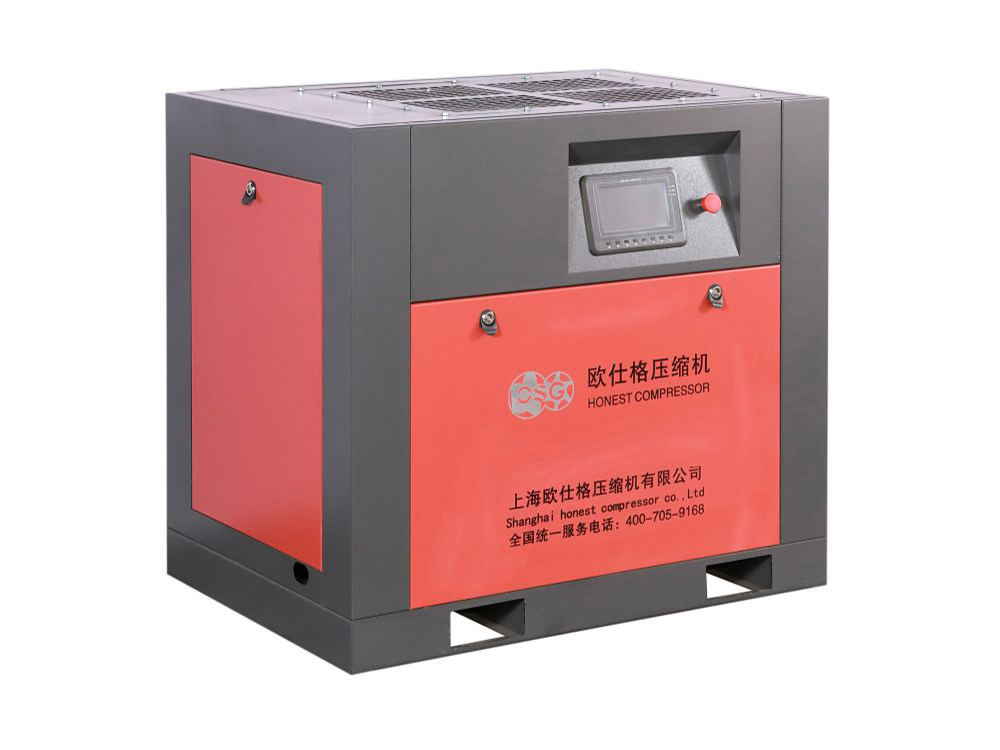

Product Pictures

Product Specification

| ETSV- series technical parameters: | |||||||||||||||||||

| Model | ETSV-18A | ETSV-22A | ETSV-30A | ETSV-37A/W | ETSV-45A/W | ETSV-55A/W | ETSV-75A/W | ETSV-90A/W | ETSV-110A/W | ETSV-132A/W | ETSV-160A/W | ETSV-185A/W | ETSV-200A/W | ETSV-220A/W | ETSV-250W | ETSV-280A/W | ETSV-315A/W | ETSV-355W | |

| Model | ETSV-18A | ETSV-22A | ETSV-30A | ETSVV-37A/W | ETSVV-45A/W | ETSVV-55A/W | ETSVV-75A/W | ETSVV-90A/W | ETSVV-110A/W | ETSVV-132A/W | ETSVV-160A/W | ETSVV-185A/W | ETSVV-200A/W | ETSVV-220A/W | ETSVV-250W | ETSVV-280A/W | ETSVV-315A/W | ETSVV-355W | |

| Free air delivery/Discharge air pressure (M3/min/ Mpa) | 3.5/0.7 | 4.1/0.7 | 6.5/0.7 | 7.1/0.7 | 9.8/0.7 | 12.8/0.7 | 17.6/0.7 | 21.0/0.7 | 24.5/0.7 | 29.9/0.7 | 34.5/0.7 | 41.0/0.7 | 44.7/0.7 | 48.6/0.7 | 55.0/0.7 | 61.0/0.7 | 69.0/0.7 | 78.0/0.7 | |

| 3.4/0.8 | 4.0/0.8 | 6.4/0.8 | 7.0/0.8 | 9.7/0.8 | 12.4/0.8 | 16.6/0.8 | 19.8/0.8 | 23.6/0.8 | 28.0/0.8 | 15.8/0.8 | 20.0/0.8 | 43.0/0.8 | 46.9/0.8 | 54.0/0.8 | 59.9/0.8 | 67.6/0.8 | 76.0/0.8 | ||

| 3.0/1.0 | 3.4/1.0 | 4.8/1.0 | 6.2/1.0 | 7.8/1.0 | 9.7/1.0 | 12.4/1.0 | 17.9/1.0 | 19.8/1.0 | 23.5/1.0 | 14.2/1.0 | 17.5/1.0 | 38.5/1.0 | 41.0/1.0 | 45.9/1.0 | 51.0/1.0 | 61.0/1.0 | 69.0/1.0 | ||

| 2.4/1.3 | 3.2/1.3 | 4.1/1.3 | 5.5/1.3 | 6.6/1.3 | 8.7/1.3 | 11.1/1.3 | 14.2/1.3 | 17.5/1.3 | 19.8/1.3 | 11.6/1.3 | 14.3/1.3 | 32.9/1.3 | 38.0/1.3 | 40.0/1.3 | 44.9/1.3 | 51.0/1.3 | 58.0/1.3 | ||

| Air supply temperature | ≤ambient temperature +8~15ºC | ||||||||||||||||||

| Motor | Power (kw/hp) | 18.5/25 | 22/30 | 30/40 | 37/50 | 45/60 | 55/75 | 75/100 | 90/120 | 110/150 | 132/175 | 160/215 | 185/250 | 200/270 | 220/294 | 250/355 | 280/375 | 315/420 | 355/475 |

| Start method | Y-△Starter/VSD start | ||||||||||||||||||

| Voltage (v/hz) | 380V 3PH 50HZ (380V-3PH-60HZ/ 460V- 3PH- 60HZ/ 220V- 3PH-60HZ/ 400V-3PH-50HZ/6000V-3PH-50HZ/other voltagesd can be customized ) | ||||||||||||||||||

| Drive method | Coupling transmission | ||||||||||||||||||

| Oil content (PPM) | ≤3 | ||||||||||||||||||

| Connector inch | 1" | 1" | 1" | 1 1/4" | 2" | 2" | 2" | DN65 | DN65 | DN65 | DN80 | DN100 | DN100 | DN100 | DN100 | DN100 | DN125 | DN125 | |

| Dimension | length mm | 1500 | 1500 | 1800 | 1800 | 2100 | 2100 | 2200 | 2700 | 2700 | 2800 | 2800 | 3200 | 3200 | 3200 | 3550 | 3550 | 3750 | 3750 |

| width mm | 900 | 900 | 1100 | 1100 | 1260 | 1260 | 1260 | 1600 | 1600 | 1700 | 1800 | 2200 | 2200 | 2200 | 2300 | 2300 | 2400 | 2400 | |

| height mm | 1150 | 1150 | 1350 | 1350 | 1600 | 1600 | 1600 | 1950 | 1950 | 1900 | 1900 | 2300 | 2300 | 2300 | 2350 | 2350 | 2350 | 2350 | |

| Weight (kg) | 680 | 730 | 980 | 1080 | 1628 | 1700 | 2256 | 2280 | 3300 | 3750 | 3770 | 3990 | 4890 | 5500 | 6000 | 6500 | 7000 | 7500 | |

| Weight (kg) | 665 | 700 | 950 | 1000 | 1590 | 1650 | 2200 | 2230 | 3200 | 3300 | 3600 | 3800 | 4700 | 5300 | 5850 | 6340 | 6850 | 6300 | |

Smart display screen Feature:Intelligent control system Advantage:10 inch monitor to show all the date Benefit:Simple operation and trouble freeAir inlet valve Feature:High vacuum degree:700mmHg Advantage:Large suction area, Low load energy consumption in unloaded operation. Fast check: prevent unloading and shutdown oil injection Benefit:Cast aluminum to avoid rust and temperature change

Smart display screen Feature:Intelligent control system Advantage:10 inch monitor to show all the date Benefit:Simple operation and trouble freeAir inlet valve Feature:High vacuum degree:700mmHg Advantage:Large suction area, Low load energy consumption in unloaded operation. Fast check: prevent unloading and shutdown oil injection Benefit:Cast aluminum to avoid rust and temperature change

Air compressor installation processing

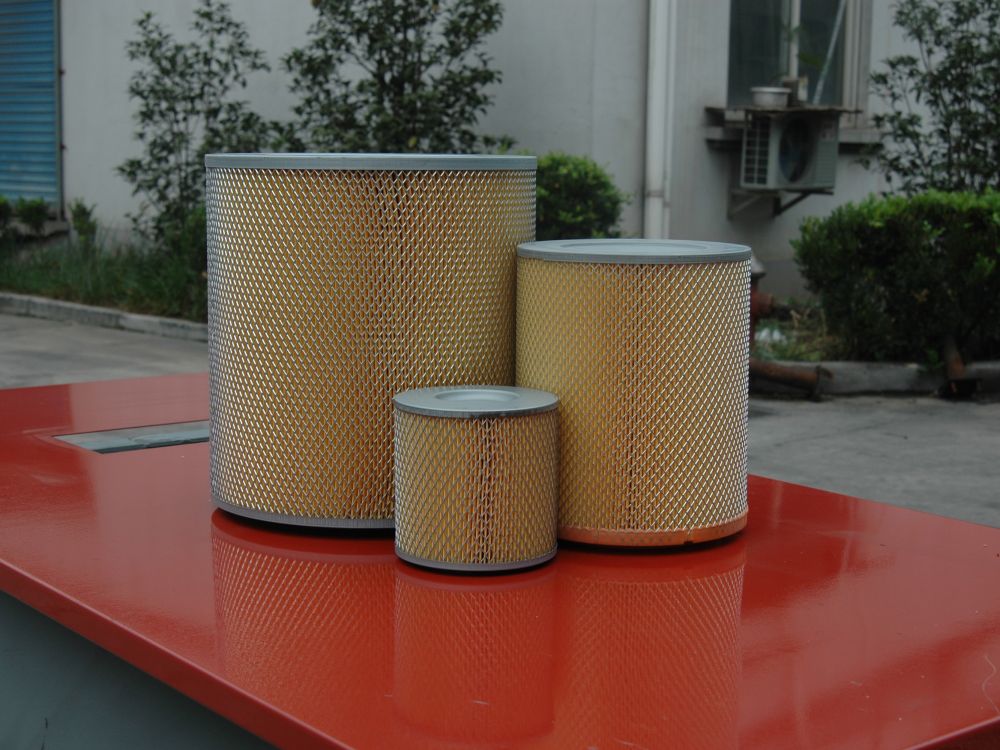

1.Air compressor 2.Valve 3.Air tank 4.Filter 5.Air dryer 6.Filter 7.Filter 8.Filter

1.Air compressor 2.Valve 3.Air tank 4.Filter 5.Air dryer 6.Filter 7.Filter 8.FilterProduction line

Packing & Loading