Top Industrial Compressors for Large-Scale Operations

By:Admin

Based in {Location}, {Company Name} has been a leading provider of industrial compressors for over 20 years. With a focus on innovation and quality, the company has built a strong reputation for providing reliable and efficient compressors for a range of industries. Their product range includes both oil-lubricated and oil-free compressors, as well as customized solutions for specific industrial applications.

One of the key features of {Company Name}'s compressors is their high efficiency and low energy consumption. This is particularly important for industrial applications, where energy costs can be a significant portion of operating expenses. By providing compressors that are designed to minimize energy usage while still delivering the necessary air pressure, {Company Name} helps its customers reduce their overall operating costs.

In addition to energy efficiency, {Company Name}'s compressors are also known for their durability and reliability. Industrial applications can be demanding, and the equipment used in these settings needs to be able to withstand harsh conditions and heavy usage. {Company Name}'s compressors are designed and built to meet these requirements, ensuring that they provide reliable performance over the long term.

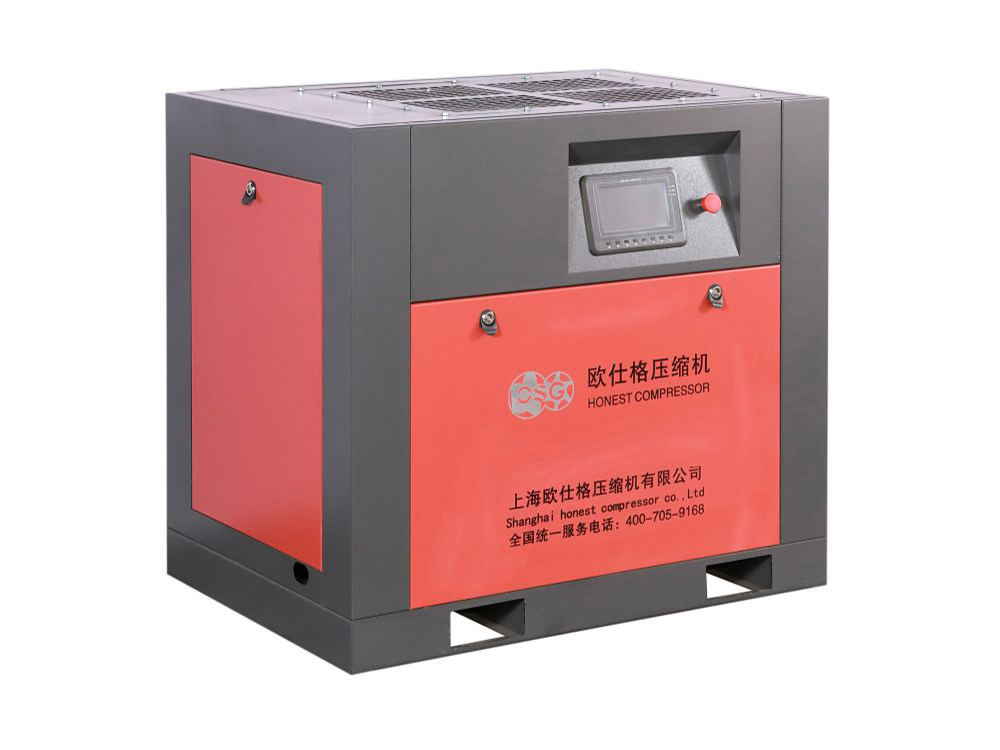

One of the standout products from {Company Name} is their line of rotary screw compressors. These compressors are known for their high performance and efficient operation. With a range of sizes and configurations available, {Company Name} offers rotary screw compressors that can meet the needs of a wide range of industrial applications.

Another area where {Company Name} excels is in providing tailored solutions for specific industrial needs. Their experienced team of engineers works closely with customers to understand their requirements and develop customized compressor solutions that meet those needs. This level of personalized service has been a key factor in {Company Name}'s success, as it allows them to provide solutions that are perfectly suited to the unique demands of each customer.

With a focus on quality, reliability, and innovation, {Company Name} has become a trusted provider of industrial compressors for companies around the world. Their commitment to delivering high-performance, energy-efficient solutions has helped them build strong relationships with their customers and establish a solid reputation in the industry.

In recent news, {Company Name} has announced the launch of a new line of large industrial compressors that are set to further enhance their product offering. These new compressors are designed to deliver even higher levels of performance and energy efficiency, meeting the evolving needs of modern industries.

The new line of large industrial compressors from {Company Name} incorporates the latest technology and engineering expertise to deliver best-in-class performance. With a focus on energy efficiency and reliability, these compressors are set to be well-received in the industry, providing customers with the high-quality solutions they have come to expect from {Company Name}.

In addition to the standard features that have made {Company Name} compressors so popular, the new line of large industrial compressors also includes advanced monitoring and control systems. These systems allow for real-time monitoring of the compressor's performance, as well as remote control capabilities for improved operational efficiency.

{Company Name} has also highlighted the durability and long-term reliability of their new large industrial compressors. These machines are built to withstand the rigors of heavy industrial use, with robust construction and high-quality materials ensuring that they can provide reliable performance over the long term.

Overall, the launch of this new line of large industrial compressors further solidifies {Company Name}'s position as a leading provider of industrial compressed air solutions. With a strong focus on quality, reliability, and innovation, {Company Name} continues to set the standard for industrial compressors, meeting the diverse needs of their customers across the globe.

As industries continue to evolve and demand for efficient compressed air solutions grows, {Company Name} remains at the forefront of providing the high-performance, energy-efficient compressors that are necessary for modern industrial applications. With their new line of large industrial compressors, {Company Name} is well-positioned to continue meeting the needs of their customers and providing the innovative solutions that have become synonymous with their brand.

Company News & Blog

Top Industrial AC Compressor Options for Your Business

Industrial Air Compressor, a leading provider of compressed air and gas equipment, has recently launched a new line of AC compressors designed to meet the needs of industrial and commercial applications. The company, with over 50 years of experience in the industry, prides itself on delivering reliable and efficient solutions for a wide range of industrial processes.The new line of AC compressors is built with the latest technology and advanced engineering to ensure maximum performance and energy efficiency. These compressors are designed to deliver high-quality compressed air for various applications, including manufacturing, pharmaceuticals, food and beverage, and automotive industries. With a focus on sustainability and environmental responsibility, Industrial Air Compressor's new line of AC compressors is also designed to minimize energy consumption and reduce carbon emissions."We are thrilled to introduce our new line of AC compressors to the market," said the spokesperson for Industrial Air Compressor. "These compressors are the result of years of research and development, and we are confident that they will set a new standard for performance and reliability in the industry."The new line of AC compressors is available in a variety of sizes and configurations to meet the specific needs of different industries and applications. Whether it's a small-scale operation or a large industrial facility, Industrial Air Compressor's AC compressors are designed to provide consistent and reliable compressed air supply to keep production running smoothly.In addition to their exceptional performance, the new line of AC compressors also comes with advanced control and monitoring systems, allowing users to optimize their operations and reduce downtime. These features enable users to monitor and manage the compressor's performance in real-time, ensuring maximum efficiency and productivity.Industrial Air Compressor is committed to providing comprehensive support and maintenance services for its new line of AC compressors. With a global network of trained technicians and service centers, the company ensures that its customers receive prompt and reliable service whenever they need it. This commitment to customer satisfaction sets Industrial Air Compressor apart from its competitors and establishes it as a trusted partner for businesses seeking reliable compressed air solutions."We understand the critical role that compressed air plays in industrial processes, and we are dedicated to ensuring that our customers have access to the best equipment and support services," the spokesperson added. "With our new line of AC compressors, we aim to exceed our customers' expectations and deliver unmatched value to their operations."Industrial Air Compressor's new line of AC compressors has already garnered positive feedback from early adopters, who have praised their performance, reliability, and energy efficiency. With a strong track record of delivering innovative and reliable compressed air solutions, Industrial Air Compressor continues to solidify its position as a leader in the industry.As industries continue to evolve and demand more efficient and sustainable solutions, Industrial Air Compressor remains at the forefront of innovation, continuously developing new technologies and products to meet the changing needs of its customers. The company's commitment to excellence, combined with its extensive experience and expertise, makes it a valuable partner for businesses looking to optimize their operations and achieve greater efficiency.The launch of the new line of AC compressors further demonstrates Industrial Air Compressor's dedication to providing cutting-edge solutions that empower businesses to thrive in today's competitive market. With a focus on quality, reliability, and sustainability, Industrial Air Compressor sets a new standard for compressed air solutions and reaffirms its position as a trusted leader in the industry.

Guide to Choosing the Perfect Oil Type for Your Industrial Air Compressor

In the world of manufacturing and industry, air compressors play an important role in powering various machinery and equipment needed for production. Industrial air compressors, in particular, are used regularly in factories, refineries, and other heavy-duty settings. These compressors tend to work under severe conditions, such as high temperatures and pressures, and are subjected to heavy stress. Thus, for optimal performance and efficiency, oil lubrication is essential. In this regard, the type of oil used becomes crucial.[Company Introduction]: One of the leading air compressor manufacturers in the market, our company has been at the forefront of providing reliable and efficient air compressors for over two decades. With continuous research and development, we have always aimed to deliver innovative and high-quality products that cater to our customer's unique needs. Our range of industrial air compressors has been designed to provide superior performance even under the most demanding conditions.Oil lubricants are essential for our industrial air compressors, providing proper lubrication to prevent wear and tear of the internal components. Using low-quality or inappropriate oil types can lead to reduced performance and short equipment life. Therefore, we have focused on combining high-quality oil and advanced technology to develop an oil type that offers optimum performance, thermal stability, anti-wear properties, and excellent oxidation resistance.[Industrial Air Compressor Oil type]: Our company's industrial air compressor oil type has been specially developed to cater to the harsh environmental conditions faced by our users. Our oil type has undergone various rigorous tests and quality checks to ensure its compatibility with our air compressors. The oil type used in our compressors has been formulated to provide superior film strength protection to internal components, preventing rust and corrosion.Additionally, our oil type has been created to enhance the overall performance of our air compressors by reducing the energy consumed in the process. The advanced technology used in the formulation of our oil type enhances the oil's viscosity index, which, in turn, leads to a lower pump discharge temperature, thereby increasing the critical life of the compressor's parts.Moreover, our industrial air compressor oil type's anti-wear properties provide long-term protection to the compressors. It also has a long shelf life, reducing maintenance costs and downtime to the user. The oil type's excellent oxidation and thermal stability prevent oxidation and carbon buildup, resulting in a cleaner and more efficient compressor. Our oil type has also been designed to perform well in low-temperature settings, making it an ideal choice for those who operate in colder environments.In conclusion, when it comes to industrial air compressors, choosing the appropriate oil type is essential for optimal performance and longevity. Our company's industrial air compressor oil type has been developed to provide superior performance, increased energy efficiency, and long-term protection to our air compressors, ensuring our customer's needs are met satisfactorily. At our company, we are committed to providing the best products and services in the market, and our industrial air compressor oil type is one example of this commitment.

Top Industrial Compressors for Large-Scale Operations

Industrial compressors are important in a wide range of industries, from manufacturing to energy production. These large machines are essential for providing the necessary pressurized air for a variety of applications, from powering pneumatic tools to running industrial processes. One company that has been at the forefront of producing large industrial compressors is {Company Name}.Based in {Location}, {Company Name} has been a leading provider of industrial compressors for over 20 years. With a focus on innovation and quality, the company has built a strong reputation for providing reliable and efficient compressors for a range of industries. Their product range includes both oil-lubricated and oil-free compressors, as well as customized solutions for specific industrial applications.One of the key features of {Company Name}'s compressors is their high efficiency and low energy consumption. This is particularly important for industrial applications, where energy costs can be a significant portion of operating expenses. By providing compressors that are designed to minimize energy usage while still delivering the necessary air pressure, {Company Name} helps its customers reduce their overall operating costs.In addition to energy efficiency, {Company Name}'s compressors are also known for their durability and reliability. Industrial applications can be demanding, and the equipment used in these settings needs to be able to withstand harsh conditions and heavy usage. {Company Name}'s compressors are designed and built to meet these requirements, ensuring that they provide reliable performance over the long term.One of the standout products from {Company Name} is their line of rotary screw compressors. These compressors are known for their high performance and efficient operation. With a range of sizes and configurations available, {Company Name} offers rotary screw compressors that can meet the needs of a wide range of industrial applications.Another area where {Company Name} excels is in providing tailored solutions for specific industrial needs. Their experienced team of engineers works closely with customers to understand their requirements and develop customized compressor solutions that meet those needs. This level of personalized service has been a key factor in {Company Name}'s success, as it allows them to provide solutions that are perfectly suited to the unique demands of each customer.With a focus on quality, reliability, and innovation, {Company Name} has become a trusted provider of industrial compressors for companies around the world. Their commitment to delivering high-performance, energy-efficient solutions has helped them build strong relationships with their customers and establish a solid reputation in the industry.In recent news, {Company Name} has announced the launch of a new line of large industrial compressors that are set to further enhance their product offering. These new compressors are designed to deliver even higher levels of performance and energy efficiency, meeting the evolving needs of modern industries.The new line of large industrial compressors from {Company Name} incorporates the latest technology and engineering expertise to deliver best-in-class performance. With a focus on energy efficiency and reliability, these compressors are set to be well-received in the industry, providing customers with the high-quality solutions they have come to expect from {Company Name}.In addition to the standard features that have made {Company Name} compressors so popular, the new line of large industrial compressors also includes advanced monitoring and control systems. These systems allow for real-time monitoring of the compressor's performance, as well as remote control capabilities for improved operational efficiency.{Company Name} has also highlighted the durability and long-term reliability of their new large industrial compressors. These machines are built to withstand the rigors of heavy industrial use, with robust construction and high-quality materials ensuring that they can provide reliable performance over the long term.Overall, the launch of this new line of large industrial compressors further solidifies {Company Name}'s position as a leading provider of industrial compressed air solutions. With a strong focus on quality, reliability, and innovation, {Company Name} continues to set the standard for industrial compressors, meeting the diverse needs of their customers across the globe.As industries continue to evolve and demand for efficient compressed air solutions grows, {Company Name} remains at the forefront of providing the high-performance, energy-efficient compressors that are necessary for modern industrial applications. With their new line of large industrial compressors, {Company Name} is well-positioned to continue meeting the needs of their customers and providing the innovative solutions that have become synonymous with their brand.

Screw Air Compressor: Reliable Solution for Air Compression Needs in Ahmedabad, India

Title: A Comprehensive Guide to Two-Stage Screw CompressorsIntroduction:In the world of industrial machinery, air compressors hold immense value due to their role in numerous applications. One such type of air compressor gaining popularity is the two-stage screw compressor. In this blog, we will delve into the workings, benefits, and applications of two-stage screw compressors, shining a light on their contribution to the industrial sector.Chapter 1: Understanding Two-Stage Screw Compressors1.1 What is a Two-Stage Screw Compressor?1.2 How does a Two-Stage Screw Compressor Function?1.3 Key Components of a Two-Stage Screw Compressor1.4 Differentiating Two-Stage Screw Compressors from Other TypesChapter 2: Benefits of Two-Stage Screw Compressors2.1 Enhanced Efficiency and Energy Savings2.2 Reduced Maintenance Requirements2.3 Higher Pressure Ratios and Capacity2.4 Superior Cooling AbilitiesChapter 3: Applications of Two-Stage Screw Compressors3.1 Manufacturing and Industrial Processes3.2 Oil and Gas Industry3.3 Petrol Stations and Automotive Services3.4 Food and Beverage Industry3.5 Pharmaceutical and Medical ApplicationsChapter 4: Choosing the Right Two-Stage Screw Compressor4.1 Factors to Consider4.2 Capacity and Pressure Requirements4.3 Maintenance and Service4.4 Noise Levels4.5 Cost and Return on InvestmentChapter 5: Suggestions to Optimize Two-Stage Screw Compressor Performance5.1 Regular Maintenance and Inspection5.2 Monitoring System Parameters5.3 Proper Operating ConditionsChapter 6: Developing a Maintenance Schedule for Two-Stage Screw Compressors6.1 Routine Inspections and Lubrication6.2 Filter Replacement6.3 Cleaning and Oiling Air Intake Grills6.4 Implementing a Compressor Maintenance LogChapter 7: ConclusionIn this comprehensive guide, we have shed light on the incredible efficiency, benefits, and applications of two-stage screw compressors. These powerful machines have revolutionized various industries, ensuring uninterrupted operations, reducing energy costs, and enhancing productivity. By understanding the basics of these compressors and implementing proper maintenance practices, businesses can make the most of their investment.Remember, when choosing a two-stage screw compressor, it is essential to consider factors such as capacity requirements, maintenance needs, noise levels, and overall cost-effectiveness. Investing in a high-quality two-stage screw compressor will undoubtedly pave the way for enhanced efficiency and improved productivity.In conclusion, two-stage screw compressors have proven their worth in numerous industries and continue to play a crucial role in the success of businesses worldwide. Whether it is in manufacturing, oil and gas, automotive, or any other sector, these compressors are a reliable and efficient solution.By choosing the right two-stage screw compressor and implementing a comprehensive maintenance schedule, businesses can experience increased productivity, energy savings, and long-term cost benefits. The reliability and performance of two-stage screw compressors make them an indispensable asset for any industry needing a consistent supply of compressed air.If you are looking for a trusted supplier of high-quality two-stage screw compressors in Ahmedabad, India, we encourage you to explore the range of compressors available at Real Air Compressors. They have a proven track record of delivering reliable and efficient compressors to a diverse range of industries.Choose a two-stage screw compressor and embrace the benefits of unparalleled efficiency, performance, and productivity!(Keywords: two-stage screw compressor, screw air compressor, screw compressor, industrial compressor, air compressor, Ahmedabad, India, Real Air Compressors)

Dry Your Compressed Air Efficiently with a Desiccant Dryer

Compressor Desiccant Dryer technology is a crucial aspect of every industrial facility that produces compressed air. Moisture is a potent enemy of compressed air systems, and if left unaddressed, it can cause leaks, corrosion, and contamination of downstream equipment. Moisture content in compressed air is usually higher than in ambient air, which necessitates the use of compressor desiccant dryers. Compressor Desiccant Dryer is an industrial air dryer technology designed to remove moisture and contaminants from compressed air, enabling it to be better suited for various industrial applications. The technology works by directing compressed air through a desiccant bed, which absorbs moisture from the air. The desiccant bed contains small beads that absorb moisture by acting as a sponge. The dryer system also includes a regeneration cycle that removes water from the desiccant by heating it and directing it out of the system. Every industrial facility that produces compressed air is aware of the fact that moisture can cause significant damage to their equipment and processes. With Compressor Desiccant Dryer technology, industrial facilities can lower their risk of contamination, reduce energy costs, increase productivity and prolong the lifespan of their equipment. For four decades, a leading manufacturer of desiccant dryers has continuously been meeting the needs of various industrial facilities across the globe. They have established an excellent reputation in the industry due to the quality and efficiency of their products. As a company dedicated to providing high-quality air treatment solutions for various industries, the company has continued to invest in cutting-edge technology and research to improve their products continually. They have a team of experts collaborating to design and manufacture the best industrial air dryers in the market. The company's Compressor Desiccant Dryer technology is designed to cater to the unique needs of various industrial facilities. They offer several models of dryers depending on the level of moisture and the air volume required, ranging from 3 to 12,000 cfm. Their Compressor Desiccant Dryer technology also features efficient filter elements, enhanced fan systems, and optimal flow paths, ensuring that customers get high-quality and reliable equipment. One of the major reasons why businesses trust this company's products is their commitment to quality assurance. They adhere to strict ISO and ASME standards to ensure that every product is of the highest quality. Their superior products have been tested, certified, and installed in various industrial facilities, making them a preferred choice worldwide. In addition, the company's customer support system is exceptional. They offer technical support before, during, and after the purchase of their products. Their team comprises highly trained professionals who provide assistance with installation, maintenance, and even troubleshooting. The company's focus is on ensuring that their customers are satisfied in every aspect, which includes offering spare parts, accessories, and regular maintenance services. The company's goal is to continue being a leading manufacturer of air treatment solutions for various industries. Their commitment is to provide exceptional products and services that meet and exceed their customer's needs. They have a strong presence in the market and have established reliable distribution channels, ensuring that their products are available worldwide. In conclusion, Compressor Desiccant Dryer technology is vital for any industrial facility producing compressed air to operate efficiently. With a commitment to quality, efficiency, and exceptional customer support, this leading desiccant dryer manufacturer continues to equip various industrial facilities worldwide with top-of-the-line equipment.

How to Use Desiccant to Keep Your Products Safe from Moisture Damage

As any industrialist knows, moisture in your compressed air system can cause serious problems. That's why desiccant compressed air dryers are such a crucial investment. Without them, your air compressors could be corroded, contaminants could be introduced to your products, and the entire system could be compromised.What is a desiccant compressed air dryer?A desiccant compressed air dryer is a device that removes moisture from compressed air systems. When air is compressed, moisture is condensed and can accumulate in the system. This moisture can lead to rust, corrosion, and bacteria growth, which can then contaminate your products or equipment.The dryer is typically composed of two towers filled with desiccant beads. As the compressed air flows through one tower, moisture is adsorbed by the desiccant beads. The dry air is then sent through the other tower to be reheated and ready for use.Types of desiccant compressed air dryersThere are two main types of desiccant compressed air dryers: heatless and heated. Heatless dryers use a portion of the dry air to regenerate the desiccant while heated dryers use an external heat source to regenerate the desiccant.Heatless dryers are ideal for smaller compressed air systems that use minimal amounts of air and have low dew points. They also have lower energy consumption than heated dryers.Heated dryers are more efficient at removing moisture at higher flow rates and high dew points. However, they require a larger compressed air system and have higher energy consumption.How to select the right desiccant compressed air dryerSelecting the right desiccant compressed air dryer depends on various factors such as the size of the compressed air system, flow rate, dew point, and operating conditions. To choose the right dryer, consider the following:1. Size of the compressed air system: The size of the system determines the required flow rate of the dryer.2. Dew point: The dew point is the temperature at which the moisture in the air becomes saturated. Different applications require different dew points.3. Operating conditions: Consider the compressed air system's operating pressure and temperature when selecting a dryer.Benefits of a desiccant compressed air dryer1. Reduced maintenance costs: Moisture accumulation in compressed air systems can corrode equipment and reduce its lifespan. Using a desiccant compressed air dryer will reduce the need for costly repairs and replacements.2. Clean air supply: The dryer removes water vapor that can cause contamination in the system's pipes, filters, and other equipment.3. Improved product quality: Moisture in compressed air systems can contaminate products and cause inconsistent output. A desiccant compressed air dryer provides dry, clean air and improves product quality.4. Energy savings: Dryer systems can reduce energy consumption and lower operating costs.ConclusionA desiccant compressed air dryer is a vital component of any compressed air system. To prevent costly repairs and equip your system with a clean, dry air supply, consider investing in a desiccant compressed air dryer. Ensure that you choose the correct size, type, and operating conditions. With a desiccant compressed air dryer, you will improve product quality and reduce operating costs.

High-efficiency Air Dryer System for Quick and Effective Drying

Air Dryer System (ADS) has revolutionized the industrial drying industry with its innovative and efficient technology. With over 20 years of experience, ADS has established itself as a leader in providing high-quality air drying solutions to a wide range of industries including food processing, pharmaceuticals, automotive, and aerospace.ADS utilizes advanced technology to deliver reliable and energy-efficient air drying systems that are tailored to meet the specific needs of each customer. The company's dedication to research and development has allowed it to continuously improve and optimize its products, ensuring that they remain at the forefront of the industry.One of the key features of ADS's air drying systems is their ability to effectively remove moisture from a variety of materials without compromising their integrity. This is achieved through a combination of advanced air flow systems and precise temperature control, resulting in fast and thorough drying without the risk of overheating or damaging the product.In addition to their efficiency, ADS's air drying systems are also designed with sustainability in mind. By minimizing energy consumption and utilizing eco-friendly materials, the company is committed to reducing its environmental footprint while helping its customers do the same.The success of ADS can be attributed to its dedicated team of professionals who are passionate about delivering exceptional products and services to their customers. From initial consultation to installation and ongoing support, the company's knowledgeable and experienced staff are committed to ensuring that each customer receives a tailored solution that meets their specific requirements.Furthermore, ADS's commitment to customer satisfaction is evident in its extensive after-sales support and maintenance services. The company understands the importance of keeping its products in optimal condition and offers comprehensive support to its customers, including regular maintenance checks and troubleshooting assistance.ADS's reputation for excellence has earned it a trusted position within the industry, with a long list of satisfied clients who have benefited from its superior air drying solutions. By consistently exceeding customer expectations and delivering on its promises, ADS has established itself as a reliable and reputable provider of air drying systems.Looking to the future, ADS is dedicated to further innovation and expansion in order to continue providing cutting-edge air drying solutions to a growing number of industries. With a strong focus on research and development, the company is committed to staying ahead of the curve and setting new standards for air drying technology.In conclusion, Air Dryer System (ADS) has emerged as a leading provider of innovative and efficient air drying solutions for a wide range of industries. With its commitment to quality, sustainability, and customer satisfaction, ADS continues to set the standard for excellence in the field of industrial drying. As the company looks ahead to further growth and innovation, it remains dedicated to delivering exceptional products and services that meet the evolving needs of its customers.

Screw Air Compressor Supplier: Leading Manufacturer of Screw Air Compressor in China

Title: Unlocking the Power of Screw Air Compressors: A Comprehensive GuideIntroduction (120 words):Welcome to our comprehensive guide on screw air compressors – the backbone of countless industries worldwide. As a leading manufacturer and supplier in China, our expertise in screw air compressors is unmatched. In this blog, we will walk you through the various aspects of these powerful machines, from their applications and benefits to the technologies behind them. Whether you are an engineer, an industry professional, or simply curious about this essential equipment, this guide will provide you with valuable insights.Keyword: Screw Air CompressorI. What is a Screw Air Compressor? (150 words)A screw air compressor is a versatile and efficient machine that converts power into potential energy stored in compressed air. Unlike reciprocating compressors, screw compressors use a rotary mechanism for compressing air. This innovative technology ensures continuous and smooth operation, making them ideal for demanding industrial applications.Keywords: Screw Air Compressor, efficient machine, compressed airII. Applications of Screw Air Compressors (200 words)1. Manufacturing Sector: Screw air compressors are widely used in various manufacturing industries, such as automobile, aerospace, textile, food, and pharmaceuticals. They power pneumatic tools, control systems, and enhance the overall efficiency of production processes.2. Oil and Gas Industry: From natural gas processing to refining operations, screw air compressors provide the necessary power to operate numerous equipment, including pumps, valves, and separators.3. Construction and Mining: Screw air compressors are essential for construction and mining equipment, powering drilling machines, jackhammers, and pneumatic tools for excavation, blasting, and material handling.4. Food and Beverage Industry: Screw air compressors ensure the hygiene standards and quality control in the food and beverage sector, assisting in bottling, packaging, and refrigeration processes.Keywords: Manufacturing, Oil and Gas Industry, Construction and Mining, Food and Beverage IndustryIII. Advantages of Screw Air Compressors (200 words)1. Energy Efficiency: Screw air compressors are designed for energy efficiency, consuming less power compared to traditional reciprocating compressors. With advanced technology and automated controls, they effectively manage air supply and demand, reducing energy costs.2. Continuous Operation: The rotary design of screw air compressors allows for continuous operation without the need for frequent pauses or rest cycles. This uninterrupted performance ensures consistent productivity and minimizes downtime.3. Reduced Noise Level: Screw air compressors are known for their quieter operation due to the absence of reciprocating parts. This is particularly beneficial in noise-sensitive environments or when the compressor is located near the workspace.4. Compact and Space-saving Design: Screw air compressors boast a compact design, saving valuable floor space in industrial settings. This allows for flexible installation in constrained areas, ensuring efficient use of facility resources.Keywords: Energy Efficiency, Continuous Operation, Reduced Noise Level, Space-saving DesignIV. Technological Innovations in Screw Air Compressors (200 words)1. Variable Speed Drive (VSD) Technology: VSD screw air compressors automatically adjust motor speed to match the compressed air demand, resulting in significant energy savings. By closely regulating air output, they eliminate wasteful operation during low-demand periods.2. Modern Control Systems: Advanced control systems in screw air compressors provide real-time monitoring, predictive maintenance, and remote monitoring capabilities. This allows operators to optimize performance, identify potential issues, and perform maintenance tasks efficiently.3. Oil-free Compression: Oil-free screw air compressors ensure clean and contaminant-free compressed air, making them an ideal choice for industries with stringent quality standards such as food, beverages, and healthcare.Keywords: Variable Speed Drive, Modern Control Systems, Oil-free CompressionConclusion (130 words):Screw air compressors are indispensable assets for a wide range of industries, offering exceptional reliability, efficiency, and versatility. As a leading Chinese manufacturer, we pride ourselves on our expertise in supplying high-quality screw air compressors that meet diverse industrial needs. By harnessing the power of these machines, businesses can optimize their production processes, enhance energy efficiency, and reduce operational costs. Whether it's manufacturing, oil and gas, construction, or food and beverage, screw air compressors continue to revolutionize industries globally. Choose a trusted supplier who understands your requirements and maximizes the potential of this remarkable technology.Keywords: Screw Air Compressor, reliability, efficiency, versatility

Powerful Industrial Air Compressor for Portable Use

Industrial Air Compressor Portable (need remove brand name) has recently announced the launch of their latest portable air compressor, designed to meet the demanding needs of industrial applications. This innovative portable air compressor is set to revolutionize the way in which industries operate, providing a reliable and efficient solution to their compressed air requirements.With advancements in technology and engineering, Industrial Air Compressor Portable (need remove brand name) has been able to develop a portable air compressor that is not only compact and lightweight, but also powerful and energy efficient. This new product is suitable for a wide range of industrial applications, including manufacturing, construction, mining, and oil and gas industries.The new portable air compressor is equipped with a high-performance motor and a durable pump, which enables it to deliver a consistent and reliable source of compressed air. Its compact size and lightweight design make it easy to transport and maneuver around the job site, providing flexibility and convenience to industrial operators. Additionally, the air compressor is designed to operate quietly, minimizing noise disruptions in the workplace.In addition to its impressive performance, the portable air compressor also boasts advanced safety features and user-friendly controls. It is designed with a built-in safety valve and a pressure gauge, allowing operators to monitor and manage the compressed air output effectively. Furthermore, the air compressor is equipped with an automatic shut-off function, which activates when the desired pressure level is reached, preventing over pressurization and potential safety hazards.Industrial Air Compressor Portable (need remove brand name) has a strong commitment to sustainability and environmental responsibility. As such, this new portable air compressor is designed to be energy efficient, reducing overall energy consumption and operating costs for industrial users. By utilizing advanced technologies and innovative design, Industrial Air Compressor Portable (need remove brand name) is not only providing a reliable solution to industrial compressed air needs, but also contributing to a greener and more sustainable future.The company behind Industrial Air Compressor Portable (need remove brand name) has a long-standing reputation for excellence in the field of compressed air solutions. With years of experience and expertise, they have consistently delivered high-quality products and outstanding customer service to industrial clients around the world. Their dedication to innovation and continuous improvement has positioned them as a leading provider of compressed air solutions in the industry.Industrial Air Compressor Portable (need remove brand name) is committed to providing comprehensive support and service to their customers. In addition to the new portable air compressor, they offer a range of accessories and spare parts, as well as technical support and training programs to ensure that their clients are able to maximize the value of their investment in compressed air solutions. Furthermore, the company has a global network of authorized distributors and service centers, enabling them to provide timely and reliable assistance to their customers, wherever they may be located.The launch of the new portable air compressor marks a significant milestone for Industrial Air Compressor Portable (need remove brand name) and reaffirms their position as a leader in the industry. With a strong focus on quality, performance, and sustainability, this innovative product is set to enhance the productivity and efficiency of industrial operations, while also contributing to a safer and more sustainable work environment.In conclusion, the new Industrial Air Compressor Portable (need remove brand name) portable air compressor represents a significant advancement in the field of compressed air solutions. With its compact and lightweight design, powerful performance, advanced safety features, and energy efficiency, it is poised to make a substantial impact on industrial operations worldwide. The company's dedication to excellence and commitment to customer satisfaction further reinforces the value of this new product, solidifying their position as a trusted partner for industrial compressed air solutions.