Top Industrial Air Dryer for Efficient Drying

By:Admin

With a commitment to delivering high-quality air drying solutions, [Company Name] has been a leading manufacturer of industrial air dryers for over two decades. The company takes pride in its extensive experience and expertise in designing, engineering, and producing innovative air drying systems that meet the specific needs and requirements of industrial plants, manufacturing facilities, and commercial applications.

[Company Name] Industrial Air Dryers are known for their exceptional performance, energy efficiency, and reliability. These advanced systems are designed to effectively remove moisture, oil, and contaminants from compressed air, ensuring that the air supply is clean, dry, and free from impurities that can compromise the performance and longevity of pneumatic equipment and processes.

The range of Industrial Air Dryers offered by [Company Name] includes refrigerated dryers, desiccant dryers, and membrane dryers, each with its unique features and capabilities to address different air drying requirements. The refrigerated dryers are designed to lower the dew point of the compressed air, while desiccant dryers use adsorption to effectively remove moisture from the air. Membrane dryers, on the other hand, utilize selective permeation to dehydrate the compressed air stream.

In addition to its standard air drying systems, [Company Name] also offers custom-designed solutions to meet the specific needs of its customers. The company's team of experienced engineers and technical experts work closely with clients to understand their unique air drying requirements and provide tailored solutions that deliver optimal performance and efficiency.

One of the key strengths of [Company Name] Industrial Air Dryers is their energy-efficient design, which helps reduce operating costs and minimize environmental impact. By incorporating advanced technologies and innovative engineering, the company's air drying systems are able to deliver superior performance while consuming less energy, making them a cost-effective and sustainable choice for industrial applications.

Furthermore, [Company Name] is committed to ensuring the reliability and durability of its air drying systems. The company uses high-quality components and materials, along with rigorous testing and quality control processes, to manufacture air dryers that are built to withstand the demands of industrial environments and deliver long-term, trouble-free operation.

As a customer-centric company, [Company Name] places a strong emphasis on providing exceptional service and support to its clients. From initial consultation and system design to installation, commissioning, and after-sales service, the company works closely with customers to ensure that they receive the right air drying solution for their needs and that their systems continue to operate at peak performance.

With a solid reputation for delivering top-quality air drying solutions, [Company Name] has established itself as a trusted partner for numerous industrial and commercial clients. The company's Industrial Air Dryers are widely used in various sectors, including manufacturing, automotive, food and beverage, pharmaceutical, and many others, where clean, dry compressed air is essential for efficient and reliable operations.

In conclusion, [Company Name] Industrial Air Dryers offer advanced, energy-efficient, and reliable air drying solutions for a wide range of industrial applications. With a focus on quality, performance, and customer satisfaction, the company continues to be a leading provider of air drying systems, serving the needs of industries that rely on clean, dry compressed air for their operations.

Company News & Blog

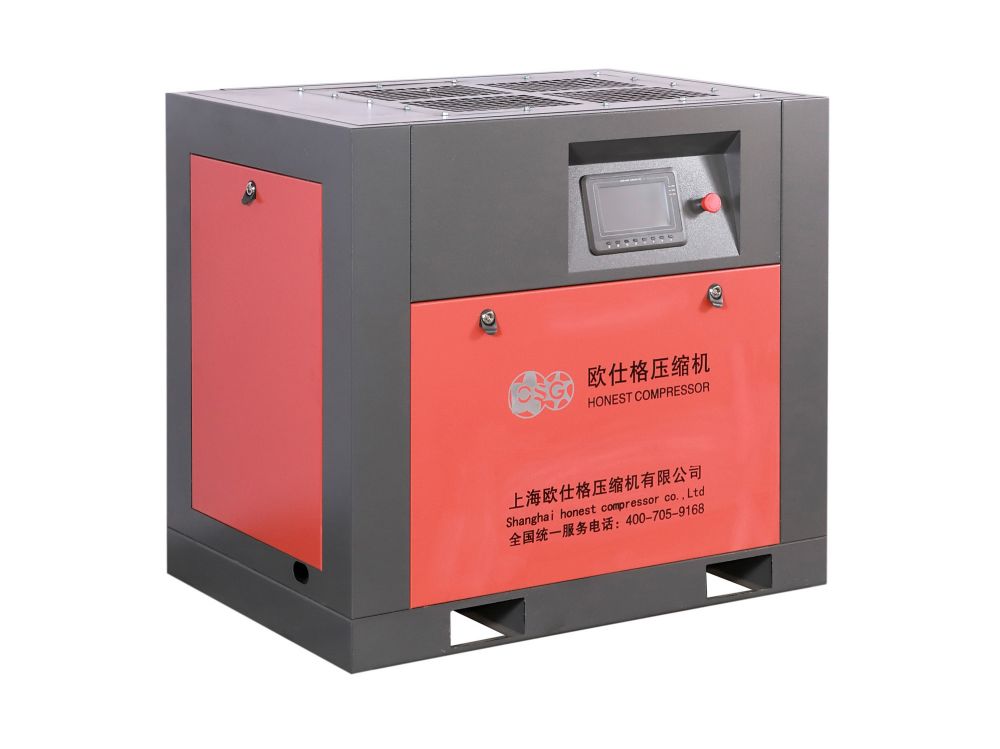

Top Electric Screw Compressor for Efficient Industrial Use

Electric Screw Compressor Revolutionizes Industrial Air CompressionThe industrial sector is constantly evolving, with new innovations and technologies driving efficiency and productivity improvements. One of the latest game-changing advancements in the field of air compression is the introduction of the Electric Screw Compressor by [Company Name], a global leader in compressed air system solutions.The Electric Screw Compressor represents a significant leap forward in the world of industrial air compression. With a focus on energy efficiency, reliability, and performance, this cutting-edge technology is set to revolutionize the way businesses manage their compressed air needs.Unlike traditional air compressors that rely on diesel or gasoline engines, the Electric Screw Compressor harnesses the power of electricity to drive its operations. This not only reduces dependency on fossil fuels but also delivers significant cost savings for industrial operators. With the shift towards sustainable and eco-friendly practices gaining momentum across industries, the Electric Screw Compressor offers a compelling solution for businesses looking to minimize their environmental impact.One of the key features of the Electric Screw Compressor is its advanced screw technology, which ensures a highly efficient and consistent supply of compressed air. This is critical for industries such as manufacturing, construction, and automotive, where a reliable source of compressed air is vital for powering tools, machinery, and equipment.Moreover, the Electric Screw Compressor is designed to deliver optimal performance in a wide range of operating conditions, making it a versatile solution for diverse industrial applications. Whether it's high-intensity production environments or remote construction sites, this innovative compressor can adapt to varying demands and deliver consistent results.In addition to its energy efficiency and performance capabilities, the Electric Screw Compressor stands out for its low maintenance requirements. The absence of traditional combustion engines eliminates the need for frequent oil changes, filter replacements, and other routine servicing tasks associated with conventional air compressors. This translates to reduced downtime, lower operating costs, and enhanced operational efficiency for businesses.[Company Name] has a strong track record of delivering high-quality compressed air system solutions to a global customer base. With a focus on innovation and customer satisfaction, the company has established itself as a trusted partner for businesses seeking reliable and efficient compressed air solutions."We are excited to introduce the Electric Screw Compressor to the market, as we believe it represents a significant advancement in the field of industrial air compression," said [Spokesperson], [Title] at [Company Name]. "Our team has worked tirelessly to develop a product that not only meets the performance and reliability expectations of our customers but also aligns with our commitment to sustainability and environmental responsibility."The Electric Screw Compressor is expected to make a significant impact on the industrial sector, offering businesses a competitive edge through improved energy efficiency, reliability, and performance. As industries continue to prioritize sustainability and operational excellence, this innovative technology is poised to become a cornerstone of modern industrial operations.In conclusion, the introduction of the Electric Screw Compressor by [Company Name] marks a significant milestone in the evolution of industrial air compression technology. With its focus on energy efficiency, reliability, and performance, this innovative solution is set to redefine the way businesses meet their compressed air needs. As the industrial sector continues to embrace sustainable practices and operational excellence, the Electric Screw Compressor stands out as a game-changing advancement that is poised to deliver long-term benefits for businesses around the world.

The Ultimate Guide to Oil Flood Screw Air Compressors

[Company Introduction]Established in 1998, our company has been dedicated to providing high-quality air compressor products and services to our customers worldwide. With a strong focus on innovation and technology, we have become a leading provider of industrial air compressors, accessories, and maintenance services in the industry.Our state-of-the-art manufacturing facilities and research and development capabilities have allowed us to consistently deliver reliable and efficient air compressor solutions that meet the demands of various industries, including manufacturing, automotive, oil and gas, and more.[News Content]Oil Flood Screw Air Compressor Revolutionizes Industry with Advanced TechnologyIn today's fast-paced industrial landscape, the demand for reliable and efficient air compressor solutions is higher than ever. As industries continue to expand and evolve, the need for innovative and advanced technology in air compression has become a priority for many companies. In response to this demand, leading air compressor manufacturer {} has introduced its latest innovation - the Oil Flood Screw Air Compressor.The Oil Flood Screw Air Compressor is a game-changer in the industry, offering a range of advanced features and benefits that set it apart from traditional air compression systems. With its cutting-edge design and state-of-the-art technology, this new compressor is poised to revolutionize the way businesses manage their air compression needs.One key feature of the Oil Flood Screw Air Compressor is its unparalleled energy efficiency. Designed with the latest energy-saving technology, this compressor is able to deliver significant cost savings to businesses by reducing power consumption and operating expenses. This not only benefits the bottom line of companies, but also aligns with the increasing demand for sustainable and eco-friendly solutions in the industry.In addition to its energy efficiency, the Oil Flood Screw Air Compressor boasts a high level of reliability and performance. Equipped with advanced control systems and built-in monitoring capabilities, this compressor can provide consistent and uninterrupted air supply, ensuring that businesses can maintain their operations without any disruptions. This level of reliability is crucial for industries that rely on compressed air for their day-to-day activities.Furthermore, the Oil Flood Screw Air Compressor is designed for easy maintenance and serviceability. Its user-friendly interface and intuitive design make it simple for operators to monitor and maintain the compressor, reducing downtime and optimizing productivity. This accessibility to maintenance is a significant advantage for businesses looking to streamline their operations and minimize potential issues.With its innovative features and advanced technology, the Oil Flood Screw Air Compressor has already garnered significant attention within the industry. Businesses across various sectors, including manufacturing, automotive, and oil and gas, have expressed interest in integrating this cutting-edge compressor into their operations to enhance efficiency and productivity.As a leading air compressor manufacturer, {} is proud to bring this revolutionary product to the market. With a strong commitment to innovation and excellence, we continue to push the boundaries of air compression technology, providing our customers with the tools they need to succeed in today's competitive business environment.In conclusion, the introduction of the Oil Flood Screw Air Compressor represents a significant advancement in the industry, offering businesses a powerful and reliable solution for their air compression needs. With its energy efficiency, reliability, and easy maintenance, this compressor is poised to make a lasting impact on the way companies manage their operations. As the demand for advanced air compression technology continues to grow, {} remains dedicated to delivering innovative solutions that meet the evolving needs of our customers and the industry as a whole.

High-Pressure 2-Stage Rotary Screw Air Compressors Ideal for Harsh Mining Environments

In today's fast-paced world, industries require advanced equipment that can cater to their needs with high precision, speed, and efficiency. One such equipment is the 2-stage rotary screw air compressor GR 110-200, which is designed to provide reliable high-pressure air supply. This compressor is specifically engineered to work in tough conditions, particularly in the mining industry, where it can deliver exceptional performance consistently.The GR 110-200 compressor operates on a 2-stage rotary screw technology, which ensures efficient and reliable performance. It can handle high pressure applications, making it an ideal choice for industries that require a continuous, reliable air supply at high pressure. The compressor has a capacity of up to 20 bar, and it combines power with precision to deliver optimum results.The GR 110-200 compressor is built with advanced features that make it perfect for mining applications. The tough working conditions in mines increase the risk of damage to equipment, but this compressor is designed to withstand these conditions. Its robust construction ensures durability, making it ideal for use in harsh environments. Additionally, the compressor is energy efficient, which reduces energy costs and ensures a lower carbon footprint.Atlas Copco Nigeria is a leading provider of industrial equipment in Nigeria. The company has been in operation for over 80 years and has a vast knowledge of the Nigerian market. It has a range of products tailored to meet the specific needs of its customers, and its equipment is widely used in various industries across the country. The company has a team of experts who provide customers with technical support, maintenance, and repairs services.Atlas Copco Nigeria is committed to customer satisfaction and has a reputation for providing high-quality products and services. The company's focus on innovation has ensured that it remains at the forefront of the industrial equipment market. With a presence in over 180 countries, Atlas Copco has a global network of experts who provide valuable insights into industry trends and developments.In conclusion, the 2-stage rotary screw air compressor GR 110-200 is an ideal choice for industries that require a reliable air supply at high pressure. Its advanced features and robust construction make it suitable for use in tough environments, particularly in mining. Atlas Copco Nigeria's commitment to customer satisfaction ensures that customers receive high-quality products and services. The company's presence in over 180 countries also provides customers with access to valuable insights into industry trends and developments.

Essential Guide to Industrial Air Dryers: Types, Uses, and Maintenance Tips

Industrial Air Dryer: A Breakthrough Technology in Drying SolutionsIn the world of manufacturing and industrial processes, the need for efficient and reliable drying solutions is paramount. With the advancement of technology, a new breakthrough in air drying technology has emerged, revolutionizing the way companies approach their drying needs. Introducing the Industrial Air Dryer, a cutting-edge drying solution that is set to change the game for businesses across various industries. This innovative technology is designed to provide optimal drying performance while minimizing energy consumption, making it a cost-effective and sustainable choice for companies seeking to improve their operations.The Industrial Air Dryer is equipped with state-of-the-art features that set it apart from traditional drying systems. Its advanced moisture control capabilities ensure that materials are dried to the desired level without the risk of over-drying or under-drying, leading to improved product quality and consistency. Additionally, its energy-efficient design allows for significant savings on operational costs, making it a financially viable option for businesses of all sizes.With an emphasis on reliability and performance, the Industrial Air Dryer is engineered to meet the demands of high-volume production environments. Its robust construction and durable components ensure long-term operation with minimal maintenance, providing companies with a dependable drying solution that can withstand the rigors of industrial settings.Furthermore, the Industrial Air Dryer is designed to be versatile and adaptable to a wide range of applications. Whether it be in the food processing industry, pharmaceutical manufacturing, or automotive production, this innovative technology can be customized to meet the specific drying requirements of different materials and processes, making it a versatile and invaluable asset for a diverse array of businesses.One of the key advantages of the Industrial Air Dryer is its user-friendly interface and intuitive controls, which facilitate ease of operation and monitoring. With features such as automated temperature and humidity regulation, as well as real-time performance monitoring, operators can effectively manage the drying process with minimal effort, leading to increased productivity and operational efficiency.In addition to its technical capabilities, the Industrial Air Dryer is also designed with sustainability in mind. By incorporating energy-saving technologies and optimizing the drying process, this innovative solution helps companies reduce their carbon footprint and contribute to environmental conservation efforts, aligning with the growing global focus on sustainable business practices.As a leading provider of industrial drying solutions, {Company Name} is proud to offer the Industrial Air Dryer to businesses seeking to enhance their drying processes. With a proven track record of delivering high-quality and reliable equipment, {Company Name} is committed to supporting its clients in achieving their production goals and maintaining a competitive edge in their respective industries.In conclusion, the Industrial Air Dryer represents a significant leap forward in drying technology, offering a combination of performance, efficiency, and sustainability that sets it apart from traditional drying systems. With its advanced features, adaptable design, and emphasis on user-friendliness, it is poised to become the go-to solution for businesses looking to optimize their drying operations. By partnering with {Company Name} to implement the Industrial Air Dryer, companies can expect to achieve improved product quality, increased cost savings, and a greener approach to their manufacturing processes.

Top Quality Screw Air Compressor for Diesel Engines

.Diesel Screw Air Compressor Provides Reliable Power for Industrial ApplicationsIn today's fast-paced industrial world, reliable and efficient power is a must. Whether it's in the construction industry, mining, or manufacturing, having a dependable source of compressed air is crucial for keeping operations running smoothly. For companies looking for a powerful and reliable solution, {Company Name}'s Diesel Screw Air Compressor is a game-changer.{Company Name} is a leading provider of industrial equipment and solutions, with a focus on delivering high-quality products that meet the needs of modern industries. With a commitment to innovation and customer satisfaction, {Company Name} has earned a reputation for excellence in the market.The Diesel Screw Air Compressor offered by {Company Name} is designed to deliver reliable and efficient compressed air for a wide range of industrial applications. With its powerful diesel engine and robust screw compressor technology, this machine is capable of meeting the demands of even the most challenging environments.One of the key advantages of {Company Name}'s Diesel Screw Air Compressor is its high level of efficiency. This compressor is designed to deliver maximum performance while minimizing energy consumption, making it a cost-effective solution for businesses looking to reduce their operational costs. Additionally, the compressor's advanced control system allows for precise monitoring and adjustment of air pressure, ensuring optimal performance at all times.In addition to its efficiency, {Company Name}'s Diesel Screw Air Compressor is also known for its durability and reliability. Built to withstand the rigors of industrial use, this compressor is engineered with high-quality components and materials, ensuring long-term performance and minimal downtime. This makes it an ideal choice for companies operating in demanding environments where reliability is paramount.Furthermore, {Company Name}'s Diesel Screw Air Compressor is designed with user-friendliness in mind. With its intuitive controls and easy maintenance requirements, this compressor is simple to operate and keep in top condition. This user-centric design not only enhances the overall user experience but also helps to minimize operational disruptions and maximize productivity.{Company Name} also takes pride in its commitment to customer support and service. With a team of highly trained technicians and a comprehensive service network, {Company Name} is dedicated to providing prompt and professional support to its customers. This ensures that businesses can rely on their Diesel Screw Air Compressor to perform at its best, day in and day out.Overall, {Company Name}'s Diesel Screw Air Compressor is a standout product in the industrial equipment market. Its combination of efficiency, reliability, and user-friendliness makes it an ideal choice for businesses seeking a powerful and dependable source of compressed air for their operations.Whether it's for construction, mining, manufacturing, or any other industrial application, {Company Name}'s Diesel Screw Air Compressor is a solution that businesses can trust to deliver the performance they need to thrive in today's competitive market.With its extensive range of features and capabilities, this compressor is a testament to {Company Name}'s commitment to providing top-quality products that meet the needs of modern industries. For businesses looking to take their operations to the next level, {Company Name}'s Diesel Screw Air Compressor is a game-changing solution that ticks all the boxes.

Ultimate Guide to Single Screw Air Compressors: Key Features, Benefits, and Applications

Innovative Single Screw Air Compressor Revolutionizes the Industry[City Name], [Date] - With a commitment to pushing the boundaries of air compression technology, [Company Name] is proud to unveil their latest breakthrough - a state-of-the-art Single Screw Air Compressor. This groundbreaking compressor has the potential to revolutionize the industry, offering enhanced efficiency, minimal maintenance, and unparalleled performance.Traditionally, air compressors have relied on multiple screws to generate compressed air. However, [Company Name]'s engineers have developed a compact single-screw design that guarantees improved energy efficiency without compromising on power. This cutting-edge technology allows customers to significantly reduce energy consumption while maximizing their productivity.The Single Screw Air Compressor employs a precisely engineered helical rotor that compresses air by rotating within a meticulously crafted chamber. This unique design eliminates the need for additional moving parts, simplifying maintenance procedures and reducing maintenance costs. By minimizing friction and wear within the compressor, this revolutionary technology ensures excellent longevity and a longer lifespan for the equipment.One of the key advantages of [Company Name]'s Single Screw Air Compressor is its ability to deliver a steady flow of compressed air, resulting in a constant and reliable supply for various industrial applications. The system is equipped with advanced control mechanisms that constantly monitor and adjust the compression process to meet the specific demands of the user. This intelligent regulation not only optimizes efficiency but also guarantees consistent, uninterrupted air supply.In addition to its superior performance, the Single Screw Air Compressor also boasts a compact footprint, making it ideal for businesses operating in space-constrained environments. Its innovative design enables installation in restricted areas while maintaining ease of access for routine maintenance and repairs. This versatility ensures that the compressor seamlessly integrates into different industries, ranging from automotive manufacturing to food processing.Furthermore, in line with [Company Name]'s commitment to environmental sustainability, the Single Screw Air Compressor incorporates eco-friendly features. With its reduced energy consumption, businesses can significantly lower their carbon footprint and contribute to a greener future. By choosing this compressor, companies not only save costs but also play an active role in preserving the environment for future generations.To ensure the utmost quality and reliability, [Company Name] conducts rigorous testing and adheres to strict international standards during the manufacturing process of its Single Screw Air Compressor. This commitment to excellence has earned them a reputation as a trusted and industry-leading provider of air compression solutions."We are excited to introduce our Single Screw Air Compressor, a game-changer in the industry," said [Spokesperson's Name], [Position] at [Company Name]. "The relentless pursuit of innovation has allowed us to address the evolving needs of our customers and provide them with exceptional performance and efficiency. We are confident that this breakthrough compressor will transform how businesses achieve their compressed air requirements."Given its exceptional energy efficiency, minimal maintenance requirements, and superior performance, [Company Name]'s Single Screw Air Compressor is set to redesign industry standards. By empowering businesses with reliable and sustainable compressed air solutions, this revolutionary system enhances productivity while minimizing operational costs. With this innovative offering, [Company Name] continues to solidify its position as a leading force in air compression technology.

Compact and Portable Screw Compressor for Versatile Use

[Company Name], a leading manufacturer of industrial machinery, has recently introduced a new portable screw compressor to their product lineup. This state-of-the-art compressor is designed to provide reliable and efficient compressed air solutions for a wide range of industrial applications.The new portable screw compressor from [Company Name] is the result of years of research and development, aimed at creating a versatile and high-performance machine that meets the needs of modern industries. The compressor is compact and lightweight, making it easy to transport and install in various working environments. Its portable design allows for flexibility and convenience, making it an ideal choice for mobile and remote operations.One of the key features of the new portable screw compressor is its powerful and energy-efficient motor. This motor is designed to deliver consistent and high-quality compressed air, while minimizing energy consumption and operating costs. This makes the compressor an environmentally friendly and cost-effective solution for businesses looking to reduce their carbon footprint and save on energy expenses.The compressor also comes equipped with advanced control systems, allowing for precise adjustment of air pressure and flow to meet specific requirements. This level of control ensures optimal performance and reliability, while also extending the lifespan of the compressor and reducing maintenance needs.In addition to its cutting-edge technology and superior performance, the new portable screw compressor from [Company Name] is also designed with user-friendliness in mind. Its intuitive interface and ergonomic design make it easy to operate and maintain, while its robust construction ensures durability and longevity even in demanding industrial settings.The portable screw compressor is available in various models and configurations, allowing businesses to choose the right machine for their specific needs. Whether it’s for construction, manufacturing, oil and gas, or other industrial applications, the new compressor offers a versatile and dependable solution for generating compressed air on the go.“At [Company Name], we are committed to providing innovative and reliable solutions for our customers’ compressed air needs,” said a spokesperson for the company. “The introduction of our new portable screw compressor is a testament to our dedication to delivering cutting-edge technology and superior performance in all our products.”With the launch of the new portable screw compressor, [Company Name] continues to solidify its position as a leading provider of compressed air solutions for industrial applications. The company’s extensive experience and expertise in the industry, combined with its commitment to innovation and quality, make it a trusted partner for businesses around the world.To learn more about the new portable screw compressor from [Company Name] and explore their complete range of industrial machinery and equipment, visit their website or contact their sales team for personalized assistance. As industries continue to evolve and demand more efficient and reliable compressed air solutions, [Company Name] remains at the forefront, offering state-of-the-art products and unparalleled support to help businesses thrive and succeed.

Small Screw Type Air Compressor: Essential Features and Uses

Small Screw Type Air Compressor: Revolutionizing the Industrial MarketComprehensive and reliable equipment is the backbone of every industrial unit. With the advancement of technology, the demand for fast, efficient, and reliable machinery has increased exponentially. When it comes to air compressors, the small screw type air compressor (let's call it SSTAC) has gained immense popularity and revolutionized the market. With exceptional performance and easy installation, this compressor has become a preferred choice for many.SSTAC is a robust and efficient compressor with a compact design. The compressor's compact structure ensures an easy installation process, making it a perfect fit for small or restricted spaces. The compact design, however, doesn't compromise on performance. SSTAC has a high output pressure range, completing the job efficiently and effectively. The manufacturers designed this compressor to cater to various industrial applications such as food processing, beverage manufacturing, laboratory testing, among others.One of the fantastic features of SSTAC is its energy efficiency. This compressor can operate at a low power utilization rate, ensuring that the unit's energy consumption is low. The low power utilization rate ensures that the total cost of ownership is low. With the cost savings, companies can channel the resources into other productive areas.Another advantage of SSTAC is its user-friendliness. Companies with trained personnel can install, operate, and maintain the compressor with ease. The compressor's user-friendliness is evident in its control system, which is simple and easy to use. The control panel is equipped with intuitive digital displays that provide detailed operational data such as the compressor's pressure and temperature.Apart from being easy to operate, the compressor's maintenance needs are minimal. Regularly scheduled maintenance of SSTAC does not require extensive downtime, allowing companies to minimize production losses due to maintenance. The compressor's reduced downtime is further enhanced by the compressor's automatic maintenance scheduling feature, saving the company's operators valuable time.The SSTAC compressor's safety is a top priority for the manufacturer. The compressor is fitted with a range of safety features that protect the compressor and its operator. One such feature is the compressor's automatic safety shut-off system. This system shuts down the compressor in the event of any abnormal operation, avoiding any damage to the compressor or injury to its operator.In summary, SSTAC is an efficient, user-friendly, and easy-to-maintain air compressor that saves on energy consumption and running costs. With its compact design, the compressor can fit into tight spaces, making the compressor an optimal choice for most companies. The compressor is suitable for various industrial applications and provides a high output pressure range to ensure that the job is completed efficiently.As mentioned earlier, a company's equipment and machinery's reliability is paramount to its operations. If the equipment fails, the business's productivity, output, and overall success are at risk. That is why companies such as (the manufacturer of SSTAC) are dedicated to producing top-of-the-range equipment that ensures businesses' success.Founded in (the year of the manufacturer's establishment), (the manufacturer of SSTAC) is a leading provider of comprehensive and innovative air compressor solutions. The company boasts of a significant presence in the global industrial market, providing exceptional customer service, and producing high-quality compressors. The manufacturer's primary objective is to provide innovative compressor engineering solutions that meet the customer's requirements while ensuring sustainability and energy efficiency. The manufacturer's facilities are equipped with the latest technological advancements in air compressor design, with highly skilled and experienced engineers and laborers who continuously research and develop new compressors.In conclusion, air compressors have become a vital part of industrial operations, and with innovations such as SSTAC, the market has become more efficient. With companies such as (the manufacturer of SSTAC) providing state-of-the-art solutions, businesses can have confidence in their equipment and achieve their production goals.

Highly efficient and powerful industrial screw air compressor on the market

Screw Air Compressor: The Efficient Solution for Industrial Air NeedsIn the ever-evolving industrial landscape, the need for reliable and efficient air compressors has become increasingly crucial. Whether it's powering pneumatic tools, controlling automation systems, or driving production processes, having a dependable source of compressed air is essential for the smooth operation of various industries. This is where the Screw Air Compressor comes into play, offering a robust and efficient solution to meet the demanding air requirements of modern manufacturing and industrial facilities.With the introduction of the Screw Air Compressor, [{Company Name}] has positioned itself as a leading provider of cutting-edge compressed air solutions for a diverse range of industrial applications. Leveraging decades of expertise in air compressor technology, the company has developed a portfolio of high-performance screw compressors that are designed to deliver exceptional reliability, energy efficiency, and low maintenance requirements.The Screw Air Compressor is a type of rotary screw compressor, which operates on the principle of positive displacement to produce compressed air. Unlike traditional piston compressors, which rely on reciprocating motion to compress air, screw compressors use rotors with helical screws to generate compressed air. This innovative design not only results in smoother, pulse-free air delivery but also allows for continuous operation without the need for a duty cycle.One of the key advantages of the Screw Air Compressor is its exceptional energy efficiency. By utilizing advanced screw compressor technology, [{Company Name}] has engineered its compressors to minimize energy consumption while maximizing air output. This is achieved through precision engineering of the compressor components, optimized rotor profiles, and intelligent control systems that ensure the compressor operates at its peak efficiency under varying load conditions.Furthermore, the Screw Air Compressor is designed with a focus on durability and reliability. The use of high-quality materials, precision manufacturing processes, and stringent quality control measures result in a compressor that is built to withstand the rigors of industrial usage. This, coupled with a comprehensive maintenance program offered by [{Company Name}], ensures that the Screw Air Compressor delivers consistent performance and longevity, thereby minimizing downtime and operational disruptions.In addition to its performance and reliability, the Screw Air Compressor offers a compact footprint and quiet operation, making it suitable for installation in a wide range of industrial settings. Whether it's a small workshop, a large manufacturing plant, or a specialized application, the Screw Air Compressor can be tailored to meet the specific air requirements of the facility, thanks to its modular design and customizable configurations.Moreover, [{Company Name}]'s commitment to customer satisfaction extends beyond the product itself. The company provides comprehensive support services, including installation, commissioning, training, and ongoing technical assistance, to ensure that the Screw Air Compressor integrates seamlessly into the customer's operations and continues to deliver optimal performance throughout its service life.The Screw Air Compressor also aligns with [{Company Name}]'s dedication to sustainability and environmental responsibility. By optimizing energy efficiency and reducing carbon emissions, the compressor helps industrial facilities meet their environmental targets and regulatory requirements while contributing to overall energy conservation efforts.As the manufacturing and industrial sectors continue to evolve and expand, the demand for reliable and efficient compressed air solutions will only continue to grow. The Screw Air Compressor from [{Company Name}] stands at the forefront of this demand, offering a technologically advanced and dependable solution that meets the diverse air needs of modern industries.In conclusion, the Screw Air Compressor represents the culmination of [{Company Name}]'s expertise, innovation, and commitment to delivering best-in-class compressed air solutions. With its exceptional energy efficiency, reliability, and tailored support services, the Screw Air Compressor is poised to become the go-to choice for industrial air needs, setting a new standard for performance and value in the compressed air industry.

How Compressed Air Systems Can Revolutionize Industrial Applications

[News Headline]Industrial Compressed Air Market Aims to Boost Efficiency with Advanced Technology[News Introduction]In today's rapidly evolving industrial landscape, the adoption of advanced technologies has become crucial for enhancing productivity and efficiency. The market for Industrial Compressed Air has recognized this need and is now introducing innovative solutions to address industry requirements. Among the key players in the market, [Brand Name] has emerged as a leading provider of cutting-edge compressed air solutions. With its commitment to delivering reliable and energy-efficient products, [Brand Name] is set to revolutionize the industry landscape.[News Content][Brand Name], a reputable company in the field of Industrial Compressed Air, is dedicated to meeting the ever-increasing demand for efficient and cost-effective compressed air solutions. Their extensive range of products caters to various industrial applications and ensures reliable and uninterrupted air supply to power critical processes.The company's dedication to innovation is reflected in its constant focus on research and development. They continuously strive to improve their product offerings, harnessing the latest advancements in technology. This pursuit has not only enabled them to stay ahead of the competition but also to provide customers with unparalleled performance and energy efficiency.One of [Brand Name]'s flagship products is their state-of-the-art air compressor system. With its cutting-edge design and advanced technological features, this compressor system sets new industry standards. The compressor is engineered to deliver consistent air pressure, enabling optimal performance and productivity across diverse industrial sectors.Energy efficiency is a prime concern in the industrial sector, and [Brand Name] understands this challenge. Therefore, they have integrated advanced energy-saving mechanisms into their compressor systems. These mechanisms ensure reduced power consumption without compromising on performance, resulting in substantial cost savings for businesses.Furthermore, [Brand Name]'s focus on sustainability sets it apart from its competitors. The company recognizes the importance of environmental stewardship and aims to minimize its carbon footprint. To achieve this, they have incorporated eco-friendly materials and components into their compressed air systems, ensuring greener operations for their customers.In addition to their commitment to technological innovation, [Brand Name] places great emphasis on customer satisfaction. They offer comprehensive after-sales services, including maintenance, repairs, and technical support. Their dedicated team of experts ensures that customers receive the highest level of service and assistance, maximizing the lifespan and performance of their compressed air systems.The growing demand for Industrial Compressed Air, fueled by expanding industrial sectors such as manufacturing, automotive, and oil and gas, presents immense opportunities for [Brand Name]. They strive to capitalize on this demand by continually refining their products to meet the evolving needs of the industry.In conclusion, [Brand Name] is playing a crucial role in shaping the Industrial Compressed Air market by delivering advanced, energy-efficient, and environmentally friendly solutions. With their focus on research and development, commitment to customer satisfaction, and dedication to sustainability, [Brand Name] is poised to lead the industry into a new era of productivity and efficiency.