- Home

- News

- Powerful Rotary Screw Gas Compressor: Enhancing Industrial Operations Through Efficient Gas Compression Technology

Powerful Rotary Screw Gas Compressor: Enhancing Industrial Operations Through Efficient Gas Compression Technology

By:Admin

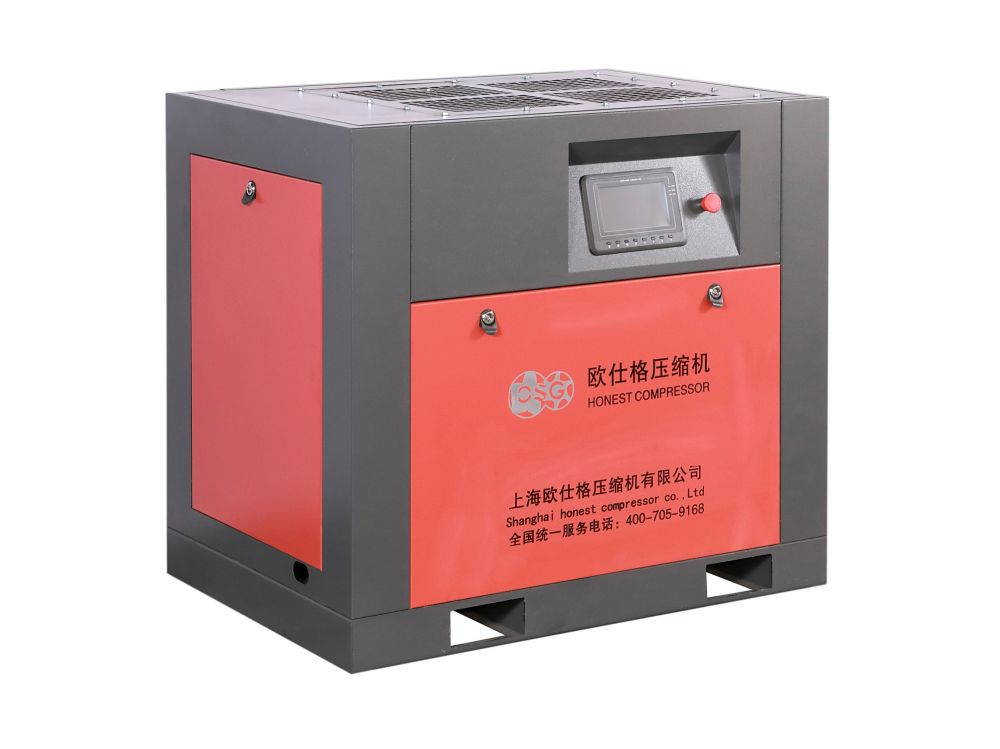

Gas compression technology has seen significant advancements in recent years, with the introduction of the Rotary Screw Gas Compressor standing as a prime example of innovation in the industry. This cutting-edge technology has revolutionized gas compression, offering improved efficiency, reliability, and performance compared to traditional reciprocating compressors.

The Rotary Screw Gas Compressor, developed by [Company Name], is designed to provide efficient and reliable compression for a wide range of gas applications, including natural gas processing, petrochemical production, and gas transmission. Its innovative design and advanced features make it a preferred choice for companies seeking to maximize their operational efficiency and minimize downtime.

One of the key benefits of the Rotary Screw Gas Compressor is its ability to deliver a consistent flow of compressed gas, ensuring reliable performance in various operating conditions. This is achieved through the use of two interlocking helical rotors that trap and compress gas as it moves through the compressor, resulting in a continuous and uniform flow of compressed gas. This feature is particularly advantageous for applications that require a steady supply of compressed gas, such as in natural gas pipelines and industrial processes.

In addition to its superior performance, the Rotary Screw Gas Compressor also offers notable energy efficiency, thanks to its advanced design and precision engineering. The compressor is equipped with state-of-the-art controls and monitoring systems that optimize its operation, enabling it to deliver maximum compression with minimal energy consumption. This not only reduces operational costs for companies but also contributes to environmental sustainability by minimizing carbon emissions.

Furthermore, the Rotary Screw Gas Compressor is designed for enhanced reliability, with robust construction and durable components that ensure long-term performance in demanding industrial environments. Its maintenance-friendly design and easy access to critical components also contribute to reduced downtime and lower maintenance costs, making it an ideal choice for companies seeking reliable and cost-effective gas compression solutions.

[Company Name] has a long-standing reputation for excellence in gas compression technology, with a strong track record of delivering innovative and high-quality solutions to its customers. With its extensive expertise and commitment to technological advancement, the company has positioned itself as a leading provider of gas compression equipment, serving a diverse range of industries and applications.

The Rotary Screw Gas Compressor is the latest addition to [Company Name]'s comprehensive portfolio of gas compression solutions, offering customers a strategic advantage in their operations through superior performance, reliability, and efficiency. With its proven capabilities and exceptional technical support, [Company Name] is well-equipped to meet the evolving needs of the gas compression market and drive the industry forward with its innovative products and solutions.

In conclusion, the Rotary Screw Gas Compressor represents a significant advancement in gas compression technology, offering a compelling combination of efficiency, reliability, and performance. With its innovative design, energy efficiency, and robust construction, it is poised to set a new standard for gas compression equipment, empowering companies to achieve their operational goals with confidence and sustainability. As it continues to gain momentum in the market, the Rotary Screw Gas Compressor is set to play a pivotal role in shaping the future of gas compression technology and driving industry progress toward a more efficient and sustainable future.

Company News & Blog

Ultimate Guide to Choosing a Pressure Dryer: What You Need to Know

[Company Name] Introduces Innovative Pressure Dryer for Efficient Drying Solutions[City, State] – [Company Name], a leading manufacturer of industrial equipment, has recently introduced a new and innovative pressure dryer designed to provide efficient drying solutions for a wide range of industries. The [Company Name] Pressure Dryer is a state-of-the-art machine that utilizes advanced technology to deliver fast and effective drying results for various materials and products.The [Company Name] Pressure Dryer is the latest addition to the company's extensive line of industrial equipment, and it is expected to set new standards in the field of drying technology. With its cutting-edge features and high-performance capabilities, the pressure dryer is poised to revolutionize the way industries approach the drying process.One of the key features of the [Company Name] Pressure Dryer is its ability to efficiently remove moisture from materials while maintaining their integrity and quality. This is particularly important for industries such as pharmaceuticals, food processing, and chemical manufacturing, where the preservation of product quality is of utmost importance. The pressure dryer is designed to handle materials with precision, ensuring that they are thoroughly dried without compromising their structural and chemical properties.In addition to its exceptional drying capabilities, the [Company Name] Pressure Dryer also offers a user-friendly interface and intuitive controls, making it easy to operate and monitor. The machine is equipped with advanced sensors and automation technology, allowing for precise control over the drying process and ensuring consistent results every time. This level of automation not only streamlines the drying process but also reduces the need for manual intervention, thereby increasing overall efficiency and productivity.Another noteworthy aspect of the [Company Name] Pressure Dryer is its energy-efficient design, which helps to minimize operational costs and environmental impact. The machine features advanced heating and airflow systems that are optimized for maximum efficiency, resulting in lower energy consumption and reduced carbon emissions. This makes the pressure dryer an environmentally friendly solution for industries seeking to enhance their sustainability practices.Furthermore, the [Company Name] Pressure Dryer is built with durability and reliability in mind, featuring a robust construction and high-quality components that are designed to withstand heavy-duty use. This ensures a long service life for the machine, allowing industries to benefit from its drying capabilities for years to come. Additionally, the pressure dryer is backed by [Company Name]'s comprehensive warranty and customer support, providing peace of mind to users and ensuring their continued satisfaction with the product.The introduction of the [Company Name] Pressure Dryer represents a significant milestone for the company, as it further solidifies [Company Name]'s position as a leading provider of innovative industrial solutions. With its unparalleled performance, user-friendly design, and energy-efficient operation, the pressure dryer is poised to make a lasting impact on the industry and set new benchmarks for drying technology.[Company Name] is committed to delivering cutting-edge solutions that enhance the efficiency and productivity of industries worldwide. The introduction of the pressure dryer is a testament to [Company Name]'s dedication to innovation and its unwavering commitment to meeting the evolving needs of its customers.In conclusion, the [Company Name] Pressure Dryer is set to redefine the standards of industrial drying, offering a compelling combination of performance, efficiency, and reliability. With its advanced technology and user-friendly features, the pressure dryer is poised to become the go-to solution for industries seeking superior drying solutions. As [Company Name] continues to lead the way in industrial innovation, the introduction of the pressure dryer marks a significant advancement in the company's quest to empower industries with cutting-edge solutions.

Highly Efficient Compact Screw Compressor for Industrial Use

Compact Screw Compressor, a leading name in the compressor industry, has revolutionized the way industries operate with their innovative and efficient compressor solutions. With a strong focus on energy efficiency, reliability, and performance, the company has established itself as a key player in the market.Founded in [year], Compact Screw Compressor has been at the forefront of compressor technology, consistently pushing the boundaries of innovation to meet the evolving needs of industries. The company's commitment to research and development has led to the creation of cutting-edge compressor systems that deliver superior performance while minimizing energy consumption. This focus on sustainability and environmentally-friendly solutions has set Compact Screw Compressor apart in the industry, earning them a reputation as a trusted and forward-thinking partner for businesses across various sectors.One of the company's flagship products is its compact screw compressor, which has garnered widespread acclaim for its high efficiency and reliability. This compressor is designed to meet the demanding requirements of modern industrial applications, delivering consistent performance in a space-saving and easy-to-maintain package. With a focus on reducing the total cost of ownership for their customers, Compact Screw Compressor's compact screw compressor is not only efficient in operation but also cost-effective in the long run.The compact screw compressor is equipped with state-of-the-art technology that optimizes its performance while ensuring smooth and quiet operation. Its advanced control system allows for precise monitoring and adjustment, maximizing energy savings and operational efficiency. Additionally, the compressor's robust design and high-quality components make it a dependable and long-lasting solution for a wide range of industrial processes.In addition to its technical capabilities, Compact Screw Compressor's compact screw compressor is also designed with the user in mind. Its user-friendly interface and easy-access service points make maintenance and operation simple and convenient. This focus on usability and accessibility reflects the company's dedication to providing comprehensive solutions that not only meet the technical requirements of their customers but also enhance the overall user experience.Moreover, Compact Screw Compressor takes pride in its commitment to customer satisfaction. The company's team of experienced professionals works closely with clients to understand their specific needs and provide tailored solutions that address their unique challenges. This customer-centric approach has earned Compact Screw Compressor a loyal and satisfied customer base, further solidifying its position as a leader in the industry.Furthermore, Compact Screw Compressor's dedication to quality is evident in its rigorous testing and quality control processes. Every compact screw compressor undergoes thorough testing to ensure that it meets the company's strict performance and reliability standards before it is delivered to the customer. This focus on quality assurance reflects Compact Screw Compressor's unwavering commitment to delivering products that uphold the highest standards of excellence.As the demand for efficient and reliable compressor solutions continues to grow, Compact Screw Compressor remains at the forefront of innovation, continuously refining and expanding its product offerings to meet the evolving needs of industries. With its unwavering commitment to excellence, sustainability, and customer satisfaction, Compact Screw Compressor is poised to remain a driving force in the compressor industry for years to come.In conclusion, Compact Screw Compressor's compact screw compressor is a testament to the company's steadfast dedication to delivering cutting-edge, reliable, and efficient compressor solutions that empower industries to operate at their best. With a relentless pursuit of innovation and a strong focus on customer satisfaction, Compact Screw Compressor is truly a name to reckon with in the compressor industry.

Discover the Advantages of Water-Injected Screw Compressors for Enhanced Performance

Water Injected Screw Compressor: A Revolutionary Solution to Energy and EfficiencyIn recent years, the need for energy-efficient equipment and solutions has become more prominent than ever before. With the rising costs of electricity and the growing environmental concerns, companies have been compelled to seek out innovative and sustainable ways to optimize their operations. This is where the Water Injected Screw Compressor comes in - a game-changing technology that promises unparalleled energy savings and performance.Firstly, what is a Water Injected Screw Compressor? It is an advanced air compression system that employs water as a cooling agent instead of traditional oil. The process involves injecting water into the compression cycle, which reduces the temperature and eliminates the need for oil lubrication. This not only results in decreased environmental impact but also leads to increased efficiency, reliability, and cost-effectiveness.One of the forerunners of this cutting-edge technology is a leading industrial air compressor manufacturer with over 100 years of experience in the industry. Their innovative Water Injected Screw Compressor has been hailed as a significant breakthrough in the field of air compression, offering exceptional performance and energy savings.The Water Injected Screw Compressor offers several benefits that make it an attractive option for various industries. Some of these advantages include:Energy Efficiency: The Water Injected Screw Compressor has a low energy consumption rate, thanks to its water cooling system. It can reduce electricity costs by up to 37%, which translates to significant savings for businesses.Increased Reliability: The elimination of oil lubrication in the compression cycle reduces the risk of system breakdowns, enhancing reliability and providing a longer lifespan for the equipment.Low Environmental Impact: The environmentally-friendly design of the Water Injected Screw Compressor eliminates oil usage, reducing the carbon footprint and promoting sustainability.Low Maintenance Cost: The simplified design of the Water Injected Screw Compressor requires less maintenance than traditional compressors, leading to reduced maintenance costs and increased uptime for businesses.Flexibility: The Water Injected Screw Compressor is versatile and can be customized to meet the specific needs of various industries, making it a practical solution for a wide range of applications.The Water Injected Screw Compressor has been widely adopted in many industries, including automotive, food and beverage, pharmaceuticals, and more. Its innovative technology has helped companies improve their operational efficiency while simultaneously reducing their environmental impact.In conclusion, the Water Injected Screw Compressor is an exceptional technology that has revolutionized air compression and set a new industry standard for efficiency and sustainability. With its incredible energy savings, increased reliability, and low environmental impact, it is a must-have solution for businesses that seek to optimize their operations and reduce their carbon footprint. Companies can rely on trusted manufacturers like ours to provide them with high-quality and customizable Water Injected Screw Compressors that meet their unique needs and drive their success.

Benefits of Using a Multi Stage Screw Compressor in Industrial Applications

Multi Stage Screw Compressor Revolutionizing the Industrial Air Compressor IndustryThe industrial air compressor industry has seen a significant revolution in recent years with the introduction of the Multi Stage Screw Compressor by a leading manufacturer in the field. This innovative and state-of-the-art compressor has set a new benchmark for energy efficiency, reliability, and performance, making it a game-changer for various industries that rely on compressed air for their operations.With a focus on providing cutting-edge solutions for the global market, the company has been a trailblazer in the development of innovative compressed air systems for industrial applications. Their commitment to research and development has led to the creation of the Multi Stage Screw Compressor, which has quickly gained recognition for its superior performance and advanced technology.Unlike traditional compressors, the Multi Stage Screw Compressor offers a multi-stage compression process that allows for higher efficiency and energy savings. This is achieved through a unique design that utilizes multiple screw elements to compress the air in stages, resulting in reduced energy consumption and lower operating costs for the end user.Furthermore, the compressor is equipped with advanced control systems that optimize its performance based on the specific air demand, ensuring consistent and reliable operation. The integration of smart technology allows for remote monitoring and diagnostics, giving users peace of mind and minimizing downtime.In addition to its outstanding performance, the Multi Stage Screw Compressor is also known for its durability and low maintenance requirements. The company has incorporated robust engineering and high-quality components to ensure long-term reliability, making it an ideal choice for industries with demanding operating conditions.One of the key advantages of the Multi Stage Screw Compressor is its adaptability to a wide range of industrial applications, including automotive, manufacturing, food and beverage, pharmaceutical, and more. Its versatility and efficiency make it a valuable asset for businesses looking to streamline their operations and reduce energy costs.The company has also emphasized sustainability in the design of the Multi Stage Screw Compressor, utilizing advanced materials and manufacturing processes to minimize environmental impact. Its energy-efficient operation contributes to lower carbon emissions, aligning with the global shift towards sustainable and eco-friendly technologies.In response to the growing demand for the Multi Stage Screw Compressor, the company has expanded its production capacity and distribution network to ensure availability in key markets worldwide. With a strong focus on customer satisfaction, the company has established a dedicated support system to provide technical assistance, maintenance services, and spare parts for the compressor.The introduction of the Multi Stage Screw Compressor has been met with enthusiasm and praise from industry experts and end users alike. Its innovative design and performance capabilities have set a new standard for industrial air compressors, elevating productivity and efficiency for businesses across various sectors.Looking ahead, the company remains committed to advancing its technology and exploring new opportunities for the Multi Stage Screw Compressor. With a strong emphasis on research and development, they are poised to continue leading the way in the industrial air compressor industry, providing innovative solutions that meet the evolving needs of the global market.In conclusion, the Multi Stage Screw Compressor represents a significant advancement in industrial air compressor technology, offering unmatched performance, energy efficiency, and reliability. Its impact on the industry is undeniable, and its introduction marks a new era of innovation and progress for businesses that rely on compressed air for their operations. As the company continues to push the boundaries of excellence, the Multi Stage Screw Compressor is set to become a cornerstone of modern industrial applications, setting new benchmarks for efficiency and sustainability in the years to come.

Reliable and Efficient Oil-Injected Screw Compressors for Railway Air Supply - Designed to Handle Harsh Environments

for Railway, GAR Oil-injected Screw Compressor, Railway Air Supply.GAR Oil-injected Screw Compressor for Reliable and Efficient Railway Air SupplyRailway transportation is a significant mode of transportation in many countries worldwide. Railways require a reliable and efficient air supply system for their operations. To ensure that the locomotives run efficiently and smoothly, it is essential to invest in the right equipment. GAR oil-injected screw compressors are ideal compressors for railway applications. They are specially designed to operate in harsh environments and provide a dependable source of compressed air.The main advantage of GAR oil-injected screw compressors lies in their superior performance. These compressors deliver efficient and reliable compressed air, enabling smooth and uninterrupted operation of railway systems. The GAR compressors are built to endure the rugged environment of the railway industry, providing long-lasting benefits for a variety of applications.One of the primary benefits of the GAR oil-injected screw compressor is its reliability. The compressor has a high uptime, ensuring that compressed air is available when it is needed. The screw compressor is designed with robust components that can withstand the rigors of the harsh railway environment. This makes the compressor a cost-effective solution for railway operators.Another advantage of GAR oil-injected screw compressors is their efficiency. The compressor design ensures that compressed air is delivered at a constant pressure, providing rail operators with consistent performance. The compressors have low energy consumption features, making it an efficient solution for railway operations.The GAR oil-injected screw compressor is built to meet the specific requirements of railway applications. It has a unique design that provides a more compact and simplified package, which makes it easy to install and maintain. GAR compressors' design is also tailored to eliminate installation costs and reduce installation time by integrating supplementary equipment, such as air dryers, to improve system efficiency.Additionally, GAR oil-injected screw compressors have a low noise level, which makes them an excellent solution for railway operations. They produce less noise, which helps to maintain a peaceful environment for railway staff and nearby residents. The low noise level also minimizes noise pollution to nearby structures.ConclusionThe GAR oil-injected screw compressor is an ideal solution for railway operators requiring a reliable and efficient air supply system. Its unique design makes it suitable for harsh railway environments, providing long-lasting benefits for a variety of applications. The compressor is easy to install and maintain, ensuring consistent performance and uptime. GAR compressors provide improved efficiency and are cost-effective solutions for railway operators. Investing in GAR oil-injected screw compressors will ensure that your railway systems run efficiently and reliably. Choose GAR compressors to achieve maximum performance with minimal maintenance.Keywords: Screw Compressor Package for Railway, GAR Oil-injected Screw Compressor, Railway Air Supply.

Small Screw Type Air Compressor: Essential Features and Uses

Small Screw Type Air Compressor: Revolutionizing the Industrial MarketComprehensive and reliable equipment is the backbone of every industrial unit. With the advancement of technology, the demand for fast, efficient, and reliable machinery has increased exponentially. When it comes to air compressors, the small screw type air compressor (let's call it SSTAC) has gained immense popularity and revolutionized the market. With exceptional performance and easy installation, this compressor has become a preferred choice for many.SSTAC is a robust and efficient compressor with a compact design. The compressor's compact structure ensures an easy installation process, making it a perfect fit for small or restricted spaces. The compact design, however, doesn't compromise on performance. SSTAC has a high output pressure range, completing the job efficiently and effectively. The manufacturers designed this compressor to cater to various industrial applications such as food processing, beverage manufacturing, laboratory testing, among others.One of the fantastic features of SSTAC is its energy efficiency. This compressor can operate at a low power utilization rate, ensuring that the unit's energy consumption is low. The low power utilization rate ensures that the total cost of ownership is low. With the cost savings, companies can channel the resources into other productive areas.Another advantage of SSTAC is its user-friendliness. Companies with trained personnel can install, operate, and maintain the compressor with ease. The compressor's user-friendliness is evident in its control system, which is simple and easy to use. The control panel is equipped with intuitive digital displays that provide detailed operational data such as the compressor's pressure and temperature.Apart from being easy to operate, the compressor's maintenance needs are minimal. Regularly scheduled maintenance of SSTAC does not require extensive downtime, allowing companies to minimize production losses due to maintenance. The compressor's reduced downtime is further enhanced by the compressor's automatic maintenance scheduling feature, saving the company's operators valuable time.The SSTAC compressor's safety is a top priority for the manufacturer. The compressor is fitted with a range of safety features that protect the compressor and its operator. One such feature is the compressor's automatic safety shut-off system. This system shuts down the compressor in the event of any abnormal operation, avoiding any damage to the compressor or injury to its operator.In summary, SSTAC is an efficient, user-friendly, and easy-to-maintain air compressor that saves on energy consumption and running costs. With its compact design, the compressor can fit into tight spaces, making the compressor an optimal choice for most companies. The compressor is suitable for various industrial applications and provides a high output pressure range to ensure that the job is completed efficiently.As mentioned earlier, a company's equipment and machinery's reliability is paramount to its operations. If the equipment fails, the business's productivity, output, and overall success are at risk. That is why companies such as (the manufacturer of SSTAC) are dedicated to producing top-of-the-range equipment that ensures businesses' success.Founded in (the year of the manufacturer's establishment), (the manufacturer of SSTAC) is a leading provider of comprehensive and innovative air compressor solutions. The company boasts of a significant presence in the global industrial market, providing exceptional customer service, and producing high-quality compressors. The manufacturer's primary objective is to provide innovative compressor engineering solutions that meet the customer's requirements while ensuring sustainability and energy efficiency. The manufacturer's facilities are equipped with the latest technological advancements in air compressor design, with highly skilled and experienced engineers and laborers who continuously research and develop new compressors.In conclusion, air compressors have become a vital part of industrial operations, and with innovations such as SSTAC, the market has become more efficient. With companies such as (the manufacturer of SSTAC) providing state-of-the-art solutions, businesses can have confidence in their equipment and achieve their production goals.

Top 5 Types of Industrial Compressor for Your Business Needs

Industrial compressors are an essential tool in various industries, including manufacturing, construction, and automotive. These machines are used to increase the pressure of a gas to generate power for various applications. There are different types of industrial compressors, each designed for specific purposes and operating conditions.One of the most common types of industrial compressors is the reciprocating compressor. This type of compressor uses a piston to compress the gas and is available in both single and multi-stage configurations. Reciprocating compressors are known for their high efficiency and reliability, making them suitable for heavy-duty industrial applications.Another type of industrial compressor is the rotary screw compressor. This type of compressor uses two meshing helical screws to compress the gas. Rotary screw compressors are known for their smooth and continuous operation, making them suitable for applications that require a constant supply of compressed air or gas.Centrifugal compressors are another type of industrial compressor that uses a rotating impeller to compress the gas. This type of compressor is known for its high flow rates and is often used in large industrial applications such as power plants and petrochemical plants.In addition to these types of compressors, there are also other specialized types such as scroll compressors, vane compressors, and axial compressors, each with unique features and applications.{Company Name} is a renowned manufacturer of industrial compressors, offering a wide range of products to meet the diverse needs of customers. The company has been in the industry for over 50 years and has established a strong reputation for delivering high-quality and reliable industrial compressors.With a team of experienced engineers and technicians, {Company Name} has the expertise to design and manufacture custom industrial compressors to meet the specific requirements of different industries. The company is committed to innovation and continuous improvement, investing in research and development to stay at the forefront of compressor technology.{Company Name} offers a comprehensive range of industrial compressors, including reciprocating, rotary screw, and centrifugal compressors, as well as specialized compressors for specific applications. The company's products are known for their robust construction, high efficiency, and long-term reliability, making them the preferred choice for many industrial applications.In addition to providing high-quality products, {Company Name} also offers comprehensive after-sales support, including maintenance, repair, and spare parts services. The company's team of service technicians is well-trained and equipped with the latest tools and equipment to ensure the smooth operation of its compressors.{Company Name}'s commitment to quality and customer satisfaction has earned it a loyal customer base and a strong presence in the industrial compressor market. The company's products are used in various industries, including manufacturing, automotive, petrochemical, and food and beverage, demonstrating their versatility and reliability.With a focus on technological innovation and customer-centric approach, {Company Name} continues to expand its product range and reach new markets, cementing its position as a leading manufacturer of industrial compressors.In conclusion, industrial compressors play a crucial role in various industries, and there are different types of compressors designed for specific applications. {Company Name} is a reputable manufacturer of industrial compressors, offering a comprehensive range of high-quality and reliable products to meet the diverse needs of its customers. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted partner for industrial compressor solutions.

The Ultimate Guide to Oil Flood Screw Air Compressors

[Company Introduction]Established in 1998, our company has been dedicated to providing high-quality air compressor products and services to our customers worldwide. With a strong focus on innovation and technology, we have become a leading provider of industrial air compressors, accessories, and maintenance services in the industry.Our state-of-the-art manufacturing facilities and research and development capabilities have allowed us to consistently deliver reliable and efficient air compressor solutions that meet the demands of various industries, including manufacturing, automotive, oil and gas, and more.[News Content]Oil Flood Screw Air Compressor Revolutionizes Industry with Advanced TechnologyIn today's fast-paced industrial landscape, the demand for reliable and efficient air compressor solutions is higher than ever. As industries continue to expand and evolve, the need for innovative and advanced technology in air compression has become a priority for many companies. In response to this demand, leading air compressor manufacturer {} has introduced its latest innovation - the Oil Flood Screw Air Compressor.The Oil Flood Screw Air Compressor is a game-changer in the industry, offering a range of advanced features and benefits that set it apart from traditional air compression systems. With its cutting-edge design and state-of-the-art technology, this new compressor is poised to revolutionize the way businesses manage their air compression needs.One key feature of the Oil Flood Screw Air Compressor is its unparalleled energy efficiency. Designed with the latest energy-saving technology, this compressor is able to deliver significant cost savings to businesses by reducing power consumption and operating expenses. This not only benefits the bottom line of companies, but also aligns with the increasing demand for sustainable and eco-friendly solutions in the industry.In addition to its energy efficiency, the Oil Flood Screw Air Compressor boasts a high level of reliability and performance. Equipped with advanced control systems and built-in monitoring capabilities, this compressor can provide consistent and uninterrupted air supply, ensuring that businesses can maintain their operations without any disruptions. This level of reliability is crucial for industries that rely on compressed air for their day-to-day activities.Furthermore, the Oil Flood Screw Air Compressor is designed for easy maintenance and serviceability. Its user-friendly interface and intuitive design make it simple for operators to monitor and maintain the compressor, reducing downtime and optimizing productivity. This accessibility to maintenance is a significant advantage for businesses looking to streamline their operations and minimize potential issues.With its innovative features and advanced technology, the Oil Flood Screw Air Compressor has already garnered significant attention within the industry. Businesses across various sectors, including manufacturing, automotive, and oil and gas, have expressed interest in integrating this cutting-edge compressor into their operations to enhance efficiency and productivity.As a leading air compressor manufacturer, {} is proud to bring this revolutionary product to the market. With a strong commitment to innovation and excellence, we continue to push the boundaries of air compression technology, providing our customers with the tools they need to succeed in today's competitive business environment.In conclusion, the introduction of the Oil Flood Screw Air Compressor represents a significant advancement in the industry, offering businesses a powerful and reliable solution for their air compression needs. With its energy efficiency, reliability, and easy maintenance, this compressor is poised to make a lasting impact on the way companies manage their operations. As the demand for advanced air compression technology continues to grow, {} remains dedicated to delivering innovative solutions that meet the evolving needs of our customers and the industry as a whole.

How Does a Desiccant Dryer Work and What are Its Benefits?

Desiccant Dryer Working: A Closer Look at How this Technology Benefits IndustriesIn the world of manufacturing and industry, the importance of maintaining optimal environmental conditions for equipment and products cannot be overstated. From the food and beverage industry to pharmaceuticals, electronics, and plastics, precise levels of humidity and dryness are critical to ensuring the quality and integrity of products.One essential piece of equipment that helps to maintain these ideal conditions is the desiccant dryer. A desiccant dryer works by removing moisture from the air, creating a dry environment that is necessary for a wide range of industrial processes.But how exactly does a desiccant dryer work, and what are the benefits of this technology for businesses? To address these questions, we turn to the leading experts in this field, {Company Name}.{Company Name}, a global leader in the manufacturing and distribution of industrial equipment, has been at the forefront of providing innovative solutions for humidity control and air treatment. With a strong emphasis on research and development, {Company Name} has continuously improved upon the design and functionality of their desiccant dryers, making them an essential component for a wide range of industries.So, what is a desiccant dryer, and how does it work? A desiccant dryer operates by passing moist air through a chamber filled with hygroscopic materials, known as desiccants. These materials have a high affinity for water vapor, effectively capturing and removing the moisture from the air. Once the desiccant material is saturated with moisture, it is regenerated through a heating process, allowing it to release the captured moisture and return to its original state, ready to remove more moisture from the air.This cyclical process of adsorption and regeneration enables desiccant dryers to consistently maintain low humidity levels, making them an invaluable tool for industries where precise control of moisture is essential.The benefits of desiccant dryers are numerous and far-reaching. By maintaining low humidity levels, these dryers help prevent corrosion, mold growth, and bacterial contamination in equipment and products. Additionally, they ensure the quality and consistency of materials, allowing for smoother manufacturing processes and reducing the risk of product defects.For the food and beverage industry, desiccant dryers play a crucial role in preserving the freshness and shelf life of products, while for pharmaceutical and electronics manufacturers, these dryers are essential for meeting strict quality control standards and regulatory requirements.{Company Name} has been a trusted partner for companies seeking reliable desiccant drying solutions. Their range of desiccant dryers is designed to accommodate various airflow capacities, making them suitable for both small-scale operations and large industrial facilities. With a commitment to quality and performance, {Company Name} has established a strong reputation for delivering cutting-edge desiccant drying technology that meets the evolving needs of modern industries.In addition to their advanced desiccant dryers, {Company Name} offers comprehensive support services, including installation, maintenance, and technical assistance, ensuring that their customers receive the necessary guidance and expertise to maximize the efficiency and longevity of their desiccant drying systems.Looking ahead, {Company Name} remains dedicated to pushing the boundaries of desiccant drying technology, with ongoing research and development initiatives aimed at enhancing the performance and energy efficiency of their dryers. By staying at the forefront of innovation, {Company Name} continues to set the standard for excellence in the field of humidity control and air treatment.In conclusion, desiccant dryers are an indispensable asset for a wide range of industries, providing critical humidity control and moisture removal capabilities that are essential for maintaining product quality and operational efficiency. With {Company Name} leading the way in the development and delivery of advanced desiccant drying solutions, businesses can be confident in their ability to achieve optimal environmental conditions and uphold the highest standards of quality and integrity.

Discover the Advantages of Industrial Oil Free Air Compressors for Efficient Operations

[Industrial Oil-Free Air Compressor] Revolutionizing the Manufacturing Industry[City, Date] - In today's manufacturing sector, efficiency, sustainability, and cleanliness are of paramount importance. With the increasing awareness of environmental concerns and the need for reducing carbon footprints, industries are embracing innovative technologies to enhance their productivity while minimizing their impact on the environment. One such groundbreaking solution that has caught the attention of manufacturers worldwide is the Industrial Oil-Free Air Compressor, designed and developed by a leading industry player.A pioneer in air compressor technology, this company has revolutionized the manufacturing industry with its state-of-the-art oil-free air compressor. Combining advanced engineering techniques with extensive research and development, they have created a compressor that offers numerous benefits to manufacturing facilities, making it an indispensable asset within industrial settings.The Industrial Oil-Free Air Compressor serves as an energy-efficient alternative to traditional oil-lubricated compressors. By eliminating the need for oil, it delivers compressed air that is entirely free from any oil contaminants. This ensures that the air meets the highest standards of purity, making it particularly suitable for industries that demand clean air, such as pharmaceuticals, food and beverages, electronics, and automotive manufacturing.Featuring cutting-edge technology, this air compressor guarantees exceptional performance, reduced maintenance costs, and minimized downtime. The advanced design utilizes a series of precision-engineered components to achieve remarkable efficiency, resulting in significant energy savings for the company. By avoiding the use of oil, manufacturers can eliminate the associated costs of oil procurement, disposal, and maintenance, leading to substantial financial savings.Moreover, the Industrial Oil-Free Air Compressor exceeds regulatory standards set by environmental agencies worldwide. With a focus on sustainability, the company has created a compressor that significantly reduces carbon emissions, contributing to a cleaner and greener environment. By eliminating oil, which is a major source of air pollution, the compressor has achieved an impressive environmental footprint. This makes it an excellent choice for companies aiming to fulfill their corporate social responsibility by adopting eco-friendly practices.The oil-free design also ensures that the compressor operates quietly, without compromising on performance. This feature is particularly valuable for manufacturing units located in urban areas or those situated in close proximity to residential areas. The reduced noise levels promote a healthier, more comfortable working environment for employees while enhancing the overall harmony within the community.In addition to these advantages, the Industrial Oil-Free Air Compressor offers unmatched reliability and durability. With rigorous quality control and meticulous testing procedures, the company guarantees that each compressor leaving their factory is of the highest standard. This reliability ensures minimal disruptions to the manufacturing process, safeguarding productivity and reducing costly downtime.With an unwavering commitment to customer satisfaction, the company not only provides cutting-edge technology but also offers exceptional customer service. A team of highly skilled engineers and technicians provides prompt assistance, ensuring that each client receives personalized support tailored to their unique requirements.As the industrial landscape continues to evolve, manufacturers must adapt to emerging trends and technologies to stay ahead in the competitive market. The Industrial Oil-Free Air Compressor represents the future of compressed air solutions, providing manufacturers with the means to improve productivity, reduce costs, and align with sustainable practices. With an emphasis on quality, efficiency, and environmental consciousness, this compressor is poised to transform the manufacturing industry, offering businesses a reliable and dynamic solution for their compressed air needs.About [Company]:[Company] is a pioneering force in the air compressor industry, specializing in innovative and sustainable compressed air solutions. With a global presence and a commitment to excellence, [Company] has established itself as a trusted provider of state-of-the-art compressors, catering to a diverse range of industries. By combining cutting-edge technology, extensive research, and unparalleled customer service, [Company] continues to shape the future of compressed air solutions worldwide.For media inquiries, please contact:[Contact Information]###