Powerful 7.5 Kw Screw Compressor Unveiled – A Breakthrough in Industrial Systems

By:Admin

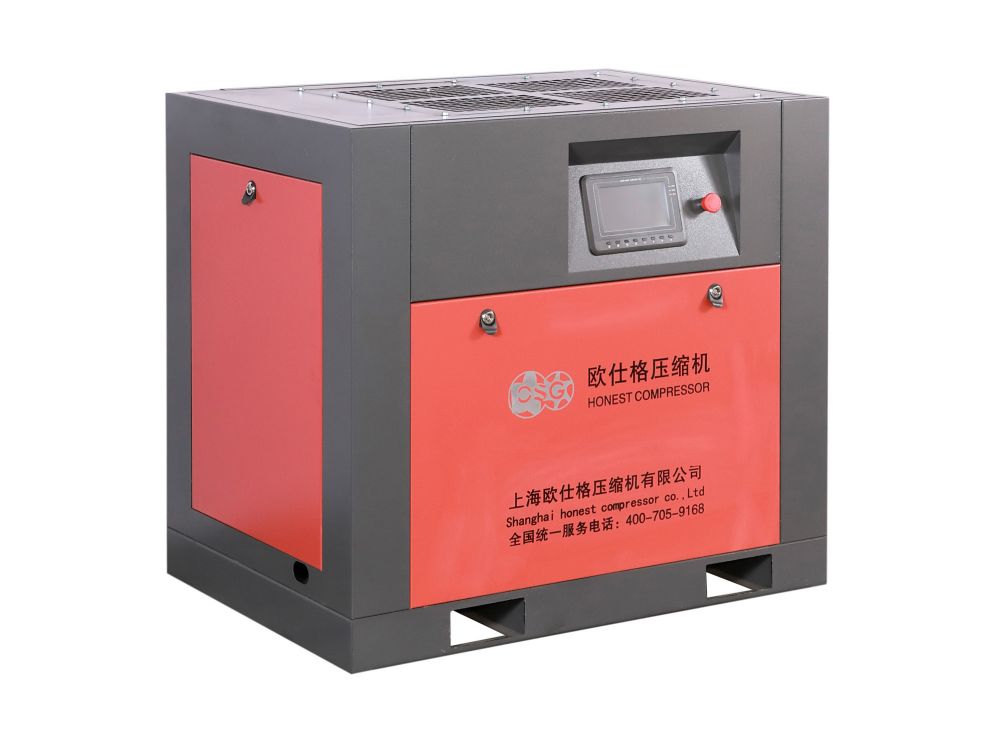

Industrial manufacturing demands advanced and reliable machinery to ensure efficient and smooth operations. With this in mind, renowned company {name removed} is proud to introduce their latest innovation—an advanced 7.5kW screw compressor. This cutting-edge compressor offers enhanced performance, unparalleled energy efficiency, and robust durability, making it an ideal choice for various industrial applications.

Built with state-of-the-art technology, this new 7.5kW screw compressor is engineered to fulfill the growing demands of diverse industries, including automotive, food processing, pharmaceuticals, and more. By consistently delivering high-quality compressed air, this compressor enhances productivity and optimizes operations while minimizing maintenance requirements and costs.

One of the key features of this compressor is its superior energy efficiency, ensuring substantial energy savings for industrial operations. Equipped with an innovative drive motor, this 7.5kW screw compressor significantly reduces energy consumption, resulting in lowered operational expenses and a reduced carbon footprint. Its advanced control system allows for precise monitoring and managing of energy usage, which enables operators to optimize performance according to their specific requirements.

Additionally, this state-of-the-art screw compressor incorporates an advanced cooling system that enhances its overall efficiency and prolongs its lifespan. The efficient cooling system effectively regulates the compressor's temperature, preventing overheating and ensuring consistent performance even in demanding industrial environments. With enhanced durability, this compressor can withstand harsh conditions and frequent use, reducing downtime and maintenance costs.

The 7.5kW screw compressor is designed for easy installation and operation, offering maximum convenience to industrial facilities. Its compact size allows for efficient use of space, ensuring it seamlessly fits into existing operations. Equipped with user-friendly controls and interfaces, this compressor enables operators to effortlessly monitor and adjust settings, facilitating smooth and trouble-free operation.

Moreover, this compressor is equipped with advanced safety features to ensure secure industrial operations. A comprehensive protection system safeguards against overloading, overheating, and other potential risks, enhancing both the operator's safety and the compressor's longevity. By prioritizing safety, {name removed} demonstrates their commitment to providing reliable and secure equipment.

Another significant advantage of choosing this 7.5kW screw compressor is its low noise emissions. Industrial operations often generate high levels of noise pollution, impacting the overall work environment and employee well-being. However, this new compressor is designed to minimize noise output, promoting a quieter workplace and ensuring a more comfortable and productive atmosphere.

In terms of maintenance, this compressor is designed to simplify and streamline the process. With strategically located service points, routine maintenance and inspections can be carried out efficiently, minimizing downtime and maximizing productivity. A user-friendly control panel provides valuable information and alerts regarding maintenance schedules and system health, facilitating proactive maintenance measures.

In conclusion, the introduction of the new 7.5kW screw compressor by {name removed} represents a significant advancement for industrial manufacturing. This cutting-edge compressor boasts superior energy efficiency, robust durability, ease of use, and enhanced safety features. With its state-of-the-art technology and advanced cooling system, this compressor guarantees reliable performance, reduced operational costs, and improved productivity. {name removed} once again demonstrates its commitment to providing innovative and reliable solutions to meet the evolving needs of the industrial sector.

Company News & Blog

Efficient Compressor Machine for Construction: A Must-Have Equipment for Builders

Introducing the New Compressor Machine Revolutionizing the Construction IndustryAs the construction industry booms and innovation continues to transform the way we build, one machine stands out as a game-changer in improving efficiency and productivity on construction sites. Enter the latest compressor machine, which has quickly become an indispensable tool for construction companies around the world. In this article, we will explore the remarkable features and benefits of this innovative device while delving into the company behind its creation.Manufactured by a leading industry player, the compressor machine is designed to optimize the power and performance required in the construction sector. Its compact and sturdy build allows for easy transport and handling, making it a popular choice for both small-scale and large-scale construction projects. The compressor machine is engineered to generate high-pressure air, enabling it to efficiently power various tools and equipment on a construction site.But what sets this compressor machine apart from others on the market? One of its standout features is its advanced control system, which enhances usability and functionality. Equipped with a user-friendly interface, operators can easily adjust and monitor air pressure, temperature, and other crucial settings, ensuring optimal performance. This intuitive control system reduces the learning curve for new users and increases overall productivity on heavy-duty tasks.Moreover, the compressor machine boasts cutting-edge technology that reduces noise levels while maintaining high efficiency. Construction sites are often plagued by excessive noise, posing risks to workers' health and causing disturbances in nearby areas. However, this compressor machine incorporates innovative noise reduction technology, making it an ideal choice for noise-sensitive environments such as urban construction sites or residential areas.In addition to its noise reduction capabilities, the compressor machine also shines in terms of energy efficiency. Energy consumption is a critical concern for construction companies, both for cost savings and environmental sustainability. This machine features an intelligent power management system that optimizes energy usage without compromising performance. By minimizing energy waste and maximizing power output, companies can significantly reduce their operational costs and carbon footprint.Furthermore, the compressor machine's advanced filtration system ensures clean and high-quality compressed air, essential for maintaining machinery and equipment longevity. Contaminants and moisture can wreak havoc on tools, causing breakdowns and costly repairs. However, this machine's filtration system efficiently removes impurities, guaranteeing reliable and continuous operation of pneumatic tools. Construction companies can now avoid unnecessary downtime and repair expenses, improving overall project efficiency and completion timelines.The company behind this groundbreaking compressor machine is recognized as a pioneer in engineering innovative solutions for the construction industry. With several decades of experience and a global presence, this company has established itself as a trusted partner for construction companies worldwide. Its commitment to research and development, as well as its adherence to strict quality assurance protocols, have resulted in top-notch products that consistently exceed industry standards.Furthermore, the company's unwavering dedication to customer satisfaction sets it apart from its competitors. It provides comprehensive after-sales support, including training programs for operators, prompt customer service, and a wide range of spare parts readily available. This commitment ensures that construction companies can maximize the benefits of the compressor machine, allowing them to complete projects efficiently and on time.In conclusion, the compressor machine introduced by [Company Name] has revolutionized the construction industry through its innovative features and remarkable benefits. From its advanced control system and noise reduction technology to its energy efficiency and impeccable filtration system, this machine proves to be an indispensable asset for construction companies around the world. With a reputable and customer-centric company behind its creation, the compressor machine is set to transform construction sites, increasing efficiency, reducing costs, and elevating overall project outcomes.

Efficient Desiccant Air Dryer for your Air Compression System - Explore now!

When it comes to air compression systems, a crucial component is the air dryer. Moisture in compressed air can cause damage to equipment, decrease efficiency, and lead to costly downtime. That's where desiccant air dryers come in - they effectively remove moisture from compressed air through a process that involves using a desiccant material to absorb the moisture.While standard desiccant air dryers are effective, they may not be the best option for every air compression system. In some cases, a heated desiccant air dryer may be a better choice. In this blog, we'll explore the benefits of heated desiccant air dryers and why they may be the right choice for your air compression system.First things first - what is a heated desiccant air dryer? As the name suggests, these air dryers use heat to regenerate the desiccant material. In a standard desiccant air dryer, the desiccant material becomes saturated with moisture over time and must be regenerated. This is typically done by depressurizing the system and allowing the desiccant to release the moisture into the atmosphere. With a heated desiccant air dryer, the desiccant is heated to release the moisture, allowing it to be used again.So why choose a heated desiccant air dryer over a standard desiccant air dryer? The main advantage is increased efficiency. When a standard desiccant air dryer regenerates its desiccant material, it requires a significant amount of energy to depressurize the system and release the moisture. With a heated desiccant air dryer, the heat is used to regenerate the desiccant, reducing the amount of energy required. This can lead to lower operating costs and increased efficiency.Another advantage of heated desiccant air dryers is their ability to handle variable inlet temperatures and flow rates. In some air compression systems, the inlet temperature and flow rate can fluctuate, which can affect the performance of a standard desiccant air dryer. Heated desiccant air dryers, on the other hand, are designed to handle these fluctuations, ensuring reliable performance in a variety of conditions.It's also worth noting that heated desiccant air dryers are available in a range of sizes and configurations, making them a versatile option for a variety of air compression systems. Whether you need a small unit for a portable compressor or a larger unit for an industrial system, there's a heated desiccant air dryer that can meet your needs.In conclusion, if you're in the market for an air dryer for your compression system, a heated desiccant air dryer may be the way to go. With increased efficiency, reliable performance in varying conditions, and a range of sizes and configurations available, a heated desiccant air dryer offers numerous benefits over a standard desiccant air dryer. Contact us today to learn more about our selection of heated desiccant air dryers and find the perfect solution for your air compression system.

Understanding Screw Compressors: A Guide to Rotary-Element Gas Compressors

Screw compressors are a type of rotary-element gas compressor that operate by compressing gas between two intermeshing, counter-rotating screws. This technology has been around since the early 20th century and has evolved over time to become one of the most efficient and reliable compressor technologies available today.One company that has been at the forefront of screw compressor design and manufacturing is [Compressor Company]. Based in [City], [Country], [Compressor Company] has been producing screw compressors for over [Number] years and has a reputation for delivering high-quality, reliable compressors to a wide range of industrial customers.One of the key advantages of screw compressors is their ability to deliver a high volume of compressed gas with low energy consumption. This is achieved through the use of a highly efficient rotor design, which allows for a greater amount of gas to be compressed with each rotation of the screws. As a result, screw compressors are often used in applications where high volumes of compressed gas are required, such as in industrial air conditioning systems, pneumatic tools, and gas pipelines.In addition to their energy efficiency, screw compressors are also known for their reliability and durability. The intermeshing design of the screws provides a continuous seal, preventing gas from leaking out and reducing the risk of mechanical failure. This makes screw compressors ideal for use in harsh operating environments where other compressor technologies may struggle to perform.[Compressor Company] has built its reputation on delivering screw compressors that are specifically designed to meet the demanding needs of industrial customers. The company's compressors are engineered to operate at high levels of efficiency, delivering optimal performance with minimal downtime. They are also built to withstand the rigors of industrial use, with robust components that are designed to last for many years.In addition to its range of standard screw compressors, [Compressor Company] also offers custom solutions for customers with unique requirements. Whether it's a compressor with a specific capacity, pressure, or power requirement, or a unit designed to operate in extreme temperatures or corrosive environments, the company has the expertise and experience to design and build a compressor that meets the customer's needs.Overall, screw compressors are a critical technology in many industrial applications, and [Compressor Company] has established itself as a leader in the field. With its focus on delivering high-quality, reliable compressors that are designed to meet the unique needs of its customers, the company is well-positioned to continue to grow and innovate in the years to come.

Explore Latest Information and Features of Air Compressor: Reviews, Photos, and More

Air compressors have revolutionized various industries, providing compressed air for countless applications. From powering pneumatic tools to operating factories and manufacturing plants, industrial compressor machines have a multitude of uses. With technological advancements, there are numerous air compressors to choose from in the market. In this blog post, we'll delve into everything you need to know about industrial compressor machines.Understanding Industrial Compressor MachinesAn industrial compressor machine is a device that converts power from an electric motor or diesel engine into potential energy stored in pressurized air. Industrial air compressors can be classified into two major types - reciprocating and rotary.Reciprocating compressors work in a similar way to car engines. Pistons inside the compressor cylinder compress air into the storage tank. While these compressors are compact and cost-effective, they are also the noisiest and have higher maintenance requirements.Rotary compressors compress air using rotating screws, lobes, or vanes. These compressors are generally quieter and have lower maintenance requirements than reciprocating compressors. However, they are also more expensive and consume more electricity.Application of Industrial Compressor MachinesIndustrial compressor machines have a multitude of applications in various industries. Some of these applications include:1. Pneumatic Tools - Industrial compressors power a wide range of pneumatic tools such as nail guns, sanders, and painting guns. By providing compressed air, they enable the smooth operation of these tools, increasing productivity in the workplace.2. Oil and Gas - Industrial compressors play a vital role in the oil and gas industry. They are used to extract gas from wells and transport oil and gas through pipelines.3. Manufacturing - Most manufacturing cases require the use of compressed air for various processes such as pressure testing, spray painting, and packaging lines.4. Mining - Compressors are used in mining operations to operate pneumatic drilling equipment and control ventilation.5. Construction - Air compressors power large construction tools such as jackhammers and concrete mixers.Factors to Consider When Choosing Industrial Compressor MachinesWhen it comes to choosing industrial compressor machines, there are several factors to keep in mind. These include:1. Type of compressor - As mentioned earlier, there are two major types of compressors. The first step is to determine which type of compressor best suits your application.2. Required airflow - The amount of compressed air required is an essential consideration. It is critical to choose a compressor that can provide adequate airflow for your application.3. Operating pressure - The operating pressure needed will depend on the application. It is important to select a compressor that can provide the required pressure levels.4. Noise level - Noise pollution is a significant concern when it comes to compressed air. Choose a compressor that operates at an acceptable noise level for your work environment.5. Maintenance requirements - Different compressors have different maintenance requirements. It is important to choose a compressor that you can maintain easily and cost-effectively.ConclusionIndustrial compressor machines are essential in various industries, providing compressed air for various processes. From choosing the right type of compressor to considering the maintenance requirements, there are several factors to keep in mind when choosing a compressor. By understanding industrial compressor machines, determining the right compressor for your application, and maintaining it correctly, you can increase productivity while reducing costs in the long run.

Improve Efficiency and Reduce Costs with a High-Quality Compressed Air System

Title: Leading Industrial Compressed Air System Provider Unveils Cutting-Edge Technology for Enhanced OperationsIntroduction:With the rapid growth of various industries, the demand for efficient industrial compressed air systems has never been higher. Catering to this need, industry-leading company [Company name removed] has emerged as a trusted provider of cutting-edge compressed air solutions. Their dedication to innovation and commitment to customer satisfaction position them at the forefront of the market. In this article, we explore [Company name removed]'s latest advancements in compressed air systems, along with the key features and benefits they offer.Paragraph 1:[Company name removed] is renowned for its state-of-the-art industrial compressed air systems, specially designed to cater to the diverse needs of the industry. The company's astute understanding of customer requirements, coupled with their commitment to technological advancements, propels them to the forefront of the market.Paragraph 2:The latest addition to [Company name removed]'s impressive lineup is the revolutionary XYZ series - a cutting-edge compressed air system that sets new standards for efficiency and reliability. Built upon years of research and development, the XYZ series surpasses industry benchmarks and addresses the challenges faced by businesses across multiple sectors.Paragraph 3:At the core of the XYZ series lies an innovative compressor unit with advanced variable speed technology. This technology enables the compressor to automatically adjust its speed based on the actual compressed air demand, resulting in significant energy savings. Furthermore, the XYZ series boasts an intelligent control system that ensures maximum operational efficiency, reducing idle time and minimizing maintenance costs.Paragraph 4:One of the key features of the XYZ series is its exceptional reliability. Built with high-quality materials and components, the system offers unmatched durability and a prolonged lifespan. Additionally, the XYZ series incorporates advanced filtration technology, providing clean and high-quality compressed air for critical applications, ensuring product safety and efficiency.Paragraph 5:In an effort to contribute to a greener environment, [Company name removed] has incorporated eco-friendly features into the XYZ series. The system boasts a high-efficiency motor that helps lower carbon emissions and a noise reduction system that enhances the working environment for employees. With its sustainable design, the XYZ series aligns perfectly with the company's commitment to environmentally conscious solutions.Paragraph 6:Recognizing the importance of after-sales support, [Company name removed] offers a comprehensive maintenance program to ensure consistent performance of their compressed air systems. Skilled technicians provide regular inspections, preventive maintenance, and emergency support, ensuring minimal downtime for businesses.Paragraph 7:In addition to driving operational efficiency, the XYZ series emphasizes ease of use. The user-friendly interface and intuitive controls streamline operations and decrease the learning curve for operators. This feature is particularly beneficial for businesses with diverse workforce backgrounds, ensuring smooth integration into existing operations.Paragraph 8:Customer testimonials and feedback offer considerable support for [Company name removed]'s commitment to customer satisfaction. Case studies highlight how the XYZ series has revolutionized operations, offering significant cost savings, increased productivity, and reduced maintenance interventions.Conclusion:[Company name removed]'s XYZ series showcases their unwavering commitment to providing state-of-the-art compressed air solutions that cater to the varying needs of industries worldwide. Through impeccable research and design, the company has developed a technologically advanced system that delivers enhanced efficiency, reliability, and eco-friendliness. As businesses continue to prioritize operational excellence, [Company name removed] stands poised to play a pivotal role in their success with their cutting-edge compressed air solutions.

Unlocking the Power of Vertical Air Compressors: A Comprehensive Guide

article about the benefits and features of a vertical air compressor and its importance in various industries.Vertical Air Compressor: The Perfect Solution for Your Industrial NeedsCompressed air is crucial to several industries, and an air compressor is the heart of many operations. Industries ranging from construction to manufacturing rely on compressed air to power their tools and equipment. The efficiency and productivity of these industries depend on high-quality compressed air systems. One of the best solutions to get your industry the necessary compressed air is a vertical air compressor.A vertical air compressor is an essential tool for many industries. It utilizes compressed air to operate various tools, such as air hammers, spray guns, and pneumatic tools such as nail guns. Vertical air compressors are the perfect option for customers that are looking for a compact, space-saving solution with high output efficiency.In its most straightforward form, a vertical air compressor works by compressing air in a tank or reservoir. The compressed air is then used to power other tools around the area. But what sets a vertical air compressor apart from other types of compressors? Here are some key benefits and features of a vertical air compressor and its importance in various industries.Benefits of a Vertical Air CompressorSpace-Saving Design: A vertical compressor takes up significantly less floor space than other horizontal models, making it an ideal choice for those with limited working area. The design allows users to put the compressor in tight corners, minimizes the amount of space needed, and provides more room to move around and get jobs done.Higher Efficiency by Storing More Compressed Air: Since vertical compressors are elongated, they can hold more compressed air than horizontal ones. This result in higher output efficiency, especially for industries that require a steady supply of compressed air.Ease of Maintenance: Aside from being a sturdy and reliable machine, vertical compressors are also easier to maintain. The vertical design allows the user to have easier access to the internal components.Less Vibration: Thanks to the vertical design, compressors do not shake as much as horizontal models. This leads to less wear and tear on the machine, increased stability, and helps extend its lifespan.Features of a Vertical Air CompressorPowerful Motors: A vertical air compressor generally has a more powerful motor, which is ideal for heavy-duty applications. It can produce more output in a shorter amount of time and can handle tougher challenges than other models.Tanks are Made of High-Quality Materials: Construction of the tank is a vital part of any compressor, and vertical compressors are no different in this regard. They are made of high-quality materials that ensure strength and durability.Oil-Lubricated or Oil-Free Operation: The vertical air compressor is available as an oil-lubricated or oil-free operation model, depending on the user's needs. Oil-lubricated compressors are well-suited for continuous use, while the oil-free version is ideal for applications that require high cleanliness levels.Importance of a Vertical Air Compressor in Various IndustriesConstruction: Some of the most vital applications that vertical air compressors are used for is in construction. Compressed air is an essential part of the construction process. Construction sites require compressed air to power everything from rock drills, jackhammers, and pneumatic nailers to power staple guns and sanders.Manufacturing: The manufacturing industry is another sector that heavily relies on compressed air from vertical compressors. These tools are used to power parts of a production process like packaging, metalworking, and the automotive sector.Automotive: Air compressors are part of many automotive workshops; they power tire air pressure sensors and clean parts of the vehicle in the detailing process.Agricultural: Compressed air has applications in the orchard and vineyard industries, like pruning and harvesting fruit and grapevines.Air compressors play a vital role in many industries, and no matter what field you're working in, you require dependable tools that can help you complete your tasks quickly and efficiently. Vertical air compressors are the ideal solution as they offer an excellent combination of efficiency and compact space-saving design.Final ThoughtsIf you're looking for an air compressor that can handle the most challenging jobs without taking up a lot of space, then a vertical air compressor is the perfect tool for you. It offers high efficiency, low vibration, and ease of maintenance, making it an exceptional investment that will pay off for years to come. Its importance cannot be underestimated, as many industries around the country depend on excellent compressed air to operate smoothly.

Reliable and Efficient Oil-Injected Screw Compressors for Railway Air Supply - Designed to Handle Harsh Environments

for Railway, GAR Oil-injected Screw Compressor, Railway Air Supply.GAR Oil-injected Screw Compressor for Reliable and Efficient Railway Air SupplyRailway transportation is a significant mode of transportation in many countries worldwide. Railways require a reliable and efficient air supply system for their operations. To ensure that the locomotives run efficiently and smoothly, it is essential to invest in the right equipment. GAR oil-injected screw compressors are ideal compressors for railway applications. They are specially designed to operate in harsh environments and provide a dependable source of compressed air.The main advantage of GAR oil-injected screw compressors lies in their superior performance. These compressors deliver efficient and reliable compressed air, enabling smooth and uninterrupted operation of railway systems. The GAR compressors are built to endure the rugged environment of the railway industry, providing long-lasting benefits for a variety of applications.One of the primary benefits of the GAR oil-injected screw compressor is its reliability. The compressor has a high uptime, ensuring that compressed air is available when it is needed. The screw compressor is designed with robust components that can withstand the rigors of the harsh railway environment. This makes the compressor a cost-effective solution for railway operators.Another advantage of GAR oil-injected screw compressors is their efficiency. The compressor design ensures that compressed air is delivered at a constant pressure, providing rail operators with consistent performance. The compressors have low energy consumption features, making it an efficient solution for railway operations.The GAR oil-injected screw compressor is built to meet the specific requirements of railway applications. It has a unique design that provides a more compact and simplified package, which makes it easy to install and maintain. GAR compressors' design is also tailored to eliminate installation costs and reduce installation time by integrating supplementary equipment, such as air dryers, to improve system efficiency.Additionally, GAR oil-injected screw compressors have a low noise level, which makes them an excellent solution for railway operations. They produce less noise, which helps to maintain a peaceful environment for railway staff and nearby residents. The low noise level also minimizes noise pollution to nearby structures.ConclusionThe GAR oil-injected screw compressor is an ideal solution for railway operators requiring a reliable and efficient air supply system. Its unique design makes it suitable for harsh railway environments, providing long-lasting benefits for a variety of applications. The compressor is easy to install and maintain, ensuring consistent performance and uptime. GAR compressors provide improved efficiency and are cost-effective solutions for railway operators. Investing in GAR oil-injected screw compressors will ensure that your railway systems run efficiently and reliably. Choose GAR compressors to achieve maximum performance with minimal maintenance.Keywords: Screw Compressor Package for Railway, GAR Oil-injected Screw Compressor, Railway Air Supply.

Small Screw Type Air Compressor: Essential Features and Uses

Small Screw Type Air Compressor: Revolutionizing the Industrial MarketComprehensive and reliable equipment is the backbone of every industrial unit. With the advancement of technology, the demand for fast, efficient, and reliable machinery has increased exponentially. When it comes to air compressors, the small screw type air compressor (let's call it SSTAC) has gained immense popularity and revolutionized the market. With exceptional performance and easy installation, this compressor has become a preferred choice for many.SSTAC is a robust and efficient compressor with a compact design. The compressor's compact structure ensures an easy installation process, making it a perfect fit for small or restricted spaces. The compact design, however, doesn't compromise on performance. SSTAC has a high output pressure range, completing the job efficiently and effectively. The manufacturers designed this compressor to cater to various industrial applications such as food processing, beverage manufacturing, laboratory testing, among others.One of the fantastic features of SSTAC is its energy efficiency. This compressor can operate at a low power utilization rate, ensuring that the unit's energy consumption is low. The low power utilization rate ensures that the total cost of ownership is low. With the cost savings, companies can channel the resources into other productive areas.Another advantage of SSTAC is its user-friendliness. Companies with trained personnel can install, operate, and maintain the compressor with ease. The compressor's user-friendliness is evident in its control system, which is simple and easy to use. The control panel is equipped with intuitive digital displays that provide detailed operational data such as the compressor's pressure and temperature.Apart from being easy to operate, the compressor's maintenance needs are minimal. Regularly scheduled maintenance of SSTAC does not require extensive downtime, allowing companies to minimize production losses due to maintenance. The compressor's reduced downtime is further enhanced by the compressor's automatic maintenance scheduling feature, saving the company's operators valuable time.The SSTAC compressor's safety is a top priority for the manufacturer. The compressor is fitted with a range of safety features that protect the compressor and its operator. One such feature is the compressor's automatic safety shut-off system. This system shuts down the compressor in the event of any abnormal operation, avoiding any damage to the compressor or injury to its operator.In summary, SSTAC is an efficient, user-friendly, and easy-to-maintain air compressor that saves on energy consumption and running costs. With its compact design, the compressor can fit into tight spaces, making the compressor an optimal choice for most companies. The compressor is suitable for various industrial applications and provides a high output pressure range to ensure that the job is completed efficiently.As mentioned earlier, a company's equipment and machinery's reliability is paramount to its operations. If the equipment fails, the business's productivity, output, and overall success are at risk. That is why companies such as (the manufacturer of SSTAC) are dedicated to producing top-of-the-range equipment that ensures businesses' success.Founded in (the year of the manufacturer's establishment), (the manufacturer of SSTAC) is a leading provider of comprehensive and innovative air compressor solutions. The company boasts of a significant presence in the global industrial market, providing exceptional customer service, and producing high-quality compressors. The manufacturer's primary objective is to provide innovative compressor engineering solutions that meet the customer's requirements while ensuring sustainability and energy efficiency. The manufacturer's facilities are equipped with the latest technological advancements in air compressor design, with highly skilled and experienced engineers and laborers who continuously research and develop new compressors.In conclusion, air compressors have become a vital part of industrial operations, and with innovations such as SSTAC, the market has become more efficient. With companies such as (the manufacturer of SSTAC) providing state-of-the-art solutions, businesses can have confidence in their equipment and achieve their production goals.

Screw Air Compressor: Reliable Solution for Air Compression Needs in Ahmedabad, India

Title: A Comprehensive Guide to Two-Stage Screw CompressorsIntroduction:In the world of industrial machinery, air compressors hold immense value due to their role in numerous applications. One such type of air compressor gaining popularity is the two-stage screw compressor. In this blog, we will delve into the workings, benefits, and applications of two-stage screw compressors, shining a light on their contribution to the industrial sector.Chapter 1: Understanding Two-Stage Screw Compressors1.1 What is a Two-Stage Screw Compressor?1.2 How does a Two-Stage Screw Compressor Function?1.3 Key Components of a Two-Stage Screw Compressor1.4 Differentiating Two-Stage Screw Compressors from Other TypesChapter 2: Benefits of Two-Stage Screw Compressors2.1 Enhanced Efficiency and Energy Savings2.2 Reduced Maintenance Requirements2.3 Higher Pressure Ratios and Capacity2.4 Superior Cooling AbilitiesChapter 3: Applications of Two-Stage Screw Compressors3.1 Manufacturing and Industrial Processes3.2 Oil and Gas Industry3.3 Petrol Stations and Automotive Services3.4 Food and Beverage Industry3.5 Pharmaceutical and Medical ApplicationsChapter 4: Choosing the Right Two-Stage Screw Compressor4.1 Factors to Consider4.2 Capacity and Pressure Requirements4.3 Maintenance and Service4.4 Noise Levels4.5 Cost and Return on InvestmentChapter 5: Suggestions to Optimize Two-Stage Screw Compressor Performance5.1 Regular Maintenance and Inspection5.2 Monitoring System Parameters5.3 Proper Operating ConditionsChapter 6: Developing a Maintenance Schedule for Two-Stage Screw Compressors6.1 Routine Inspections and Lubrication6.2 Filter Replacement6.3 Cleaning and Oiling Air Intake Grills6.4 Implementing a Compressor Maintenance LogChapter 7: ConclusionIn this comprehensive guide, we have shed light on the incredible efficiency, benefits, and applications of two-stage screw compressors. These powerful machines have revolutionized various industries, ensuring uninterrupted operations, reducing energy costs, and enhancing productivity. By understanding the basics of these compressors and implementing proper maintenance practices, businesses can make the most of their investment.Remember, when choosing a two-stage screw compressor, it is essential to consider factors such as capacity requirements, maintenance needs, noise levels, and overall cost-effectiveness. Investing in a high-quality two-stage screw compressor will undoubtedly pave the way for enhanced efficiency and improved productivity.In conclusion, two-stage screw compressors have proven their worth in numerous industries and continue to play a crucial role in the success of businesses worldwide. Whether it is in manufacturing, oil and gas, automotive, or any other sector, these compressors are a reliable and efficient solution.By choosing the right two-stage screw compressor and implementing a comprehensive maintenance schedule, businesses can experience increased productivity, energy savings, and long-term cost benefits. The reliability and performance of two-stage screw compressors make them an indispensable asset for any industry needing a consistent supply of compressed air.If you are looking for a trusted supplier of high-quality two-stage screw compressors in Ahmedabad, India, we encourage you to explore the range of compressors available at Real Air Compressors. They have a proven track record of delivering reliable and efficient compressors to a diverse range of industries.Choose a two-stage screw compressor and embrace the benefits of unparalleled efficiency, performance, and productivity!(Keywords: two-stage screw compressor, screw air compressor, screw compressor, industrial compressor, air compressor, Ahmedabad, India, Real Air Compressors)

Explore Variable Speed Lubricated Rotary Screw Compressors for Optimum Performance

Variable Speed Screw Compressors: How They Work and Their BenefitsWhen it comes to industrial air compression, variable speed screw compressors have become increasingly popular for their efficiency and ease of use. Whether you're looking to save on energy costs or improve the performance of your operation, a variable speed screw compressor might be the solution you need.So, how do variable speed screw compressors work?As the name suggests, these compressors feature a motor that can adjust its speed to meet the changing demands of your operation. When demand is low, the motor operates at a lower speed, which reduces energy consumption and wear on the compressor. As demand increases, the motor speeds up, providing the necessary airflow.Compressors that operate at a fixed speed can waste energy when the demand for air drops. This is because they continue to run at full power, even if it's unnecessary. With a variable speed screw compressor, you only use as much energy as you need, which translates to lower electricity bills and a smaller carbon footprint.Another benefit of variable speed compressors is their ability to provide consistent air pressure. Unlike fixed speed models, which may experience fluctuations in pressure during use, variable speed screw compressors maintain a stable output. This helps to prevent interruptions in production due to equipment malfunctions.Advancements in technology have also made variable speed screw compressors quieter and more reliable than ever before. Thanks to innovative designs and materials, these compressors operate with lower vibrations and produce less noise, making them ideal for use in noise-sensitive environments.In addition to these benefits, variable speed screw compressors offer a range of other features that make them a smart choice for industrial air compression. Some models, for example, come equipped with advanced monitoring and reporting capabilities, which allow you to keep track of your compressor's performance in real-time and identify potential issues before they lead to downtime.Other features to look for include:- Energy-saving modes that automatically adjust compressor output based on demand- User-friendly interfaces that make it easy to adjust settings and monitor performance- Compact, space-saving designs that take up less floor space than traditional compressorsWhether you're a facility manager or an industrial engineer, upgrading to a variable speed screw compressor can help you reduce costs, increase efficiency, and improve overall air compression performance. With so many benefits and options to choose from, there's no reason not to make the switch today.Get in touch with a reputable compressor supplier to learn more about the different variable speed screw compressor models available and find the perfect compressor that meets the demands of your operation.