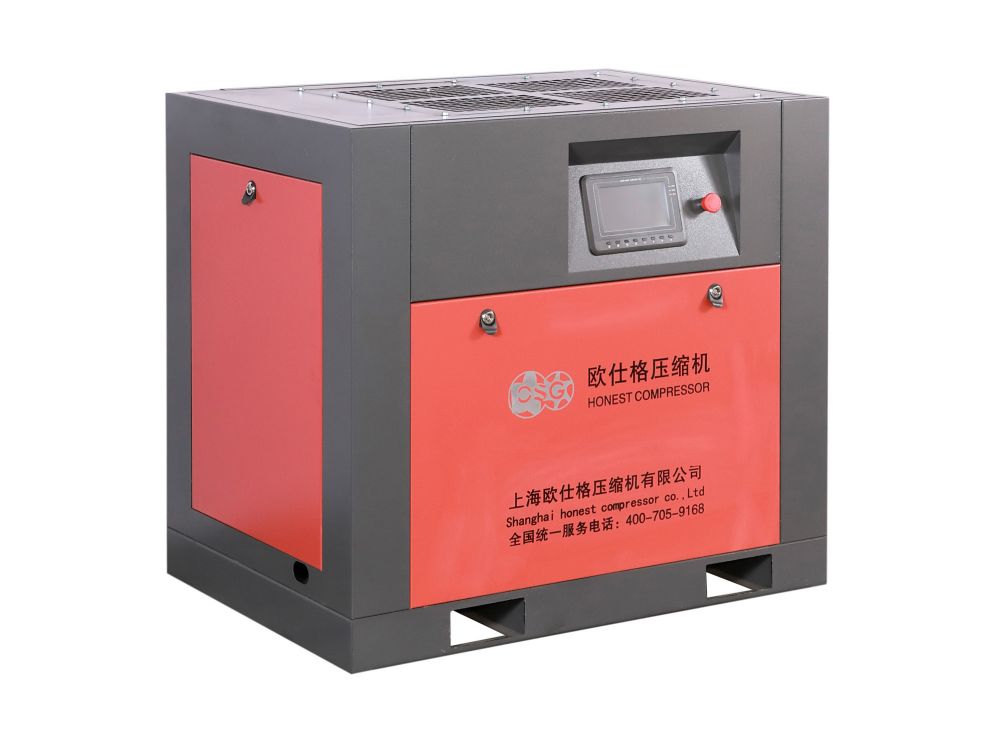

High-Quality Diesel Screw Air Compressor for Industrial Use

By:Admin

The Diesel Screw Air Compressor is designed to deliver superior air compression for a wide range of industrial operations, including manufacturing, construction, mining, and oil and gas exploration. Its robust and durable construction makes it suitable for use in harsh and demanding environments, ensuring consistent performance and reliability even in the most challenging conditions.

One of the key highlights of the Diesel Screw Air Compressor is its fuel-efficient diesel engine, which not only reduces operational costs but also minimizes environmental impact. This engine is specifically designed to optimize fuel consumption while maintaining high power output, making it an environmentally friendly choice for businesses looking to reduce their carbon footprint.

In addition to its fuel efficiency, the Diesel Screw Air Compressor is equipped with advanced control and monitoring systems that allow for seamless integration into industrial processes. The compressor can be easily configured and customized to meet specific application requirements, providing users with flexibility and control over their air compression operations.

Furthermore, [CompanyName] has ensured that the Diesel Screw Air Compressor is designed with ease of maintenance in mind. The compressor features convenient access points for routine servicing and maintenance tasks, reducing downtime and maximizing operational efficiency for businesses.

"We are excited to introduce the Diesel Screw Air Compressor to our product portfolio," said a spokesperson for [CompanyName]. "This new addition represents our commitment to providing innovative and reliable solutions to our customers. We believe that the advanced features and high performance of this compressor will add significant value to a wide range of industrial operations."

To support the launch of the Diesel Screw Air Compressor, [CompanyName] is offering comprehensive training and technical support to help customers maximize the benefits of this new product. The company's team of experts is readily available to provide guidance on installation, operation, and maintenance, ensuring that customers can leverage the full potential of the compressor in their respective applications.

As part of its dedication to customer satisfaction, [CompanyName] also offers a range of service and support packages for the Diesel Screw Air Compressor, including maintenance contracts, spare parts availability, and emergency response services. This comprehensive support is designed to give customers peace of mind and confidence in the reliability of their air compression systems.

In conclusion, the introduction of the Diesel Screw Air Compressor by [CompanyName] signifies a significant milestone in the company's commitment to delivering cutting-edge industrial solutions. With its advanced features, high performance, and comprehensive support, this new addition is poised to make a positive impact on a wide range of industrial operations, setting new standards for efficiency and reliability in air compression technology.

Company News & Blog

High-Efficiency Industrial Rotary Screw Air Compressor

Industrial Rotary Screw Air Compressor - The Engine of ProductivityIn the fast-paced world of industrial manufacturing, efficiency and productivity are key. The ability to produce high-quality products at a rapid pace is essential for remaining competitive in the market. One of the critical elements in achieving this level of efficiency lies within the machinery and equipment used in the manufacturing process. This is where the Industrial Rotary Screw Air Compressor comes into play.The Industrial Rotary Screw Air Compressor has become the engine of productivity for many industrial manufacturing companies. Its ability to provide a reliable source of compressed air for various applications has made it an essential component in the production process. From powering pneumatic tools to operating machinery, this piece of equipment has proven to be indispensable in keeping manufacturing operations running smoothly.The Industrial Rotary Screw Air Compressor works by using a rotary-type positive displacement mechanism to compress air. This method allows for a continuous supply of compressed air, making it ideal for applications that require a constant and steady stream of air. This feature is especially beneficial for industries such as automotive manufacturing, aerospace, food and beverage production, and many others.In addition to its continuous supply of compressed air, the Industrial Rotary Screw Air Compressor is known for its energy efficiency. With the rising costs of energy, manufacturers are continually seeking ways to reduce their operational expenses. The design of the Industrial Rotary Screw Air Compressor allows for high efficiency in converting power into compressed air, ultimately leading to cost savings for companies that rely on this equipment for their production needs.Furthermore, the Industrial Rotary Screw Air Compressor offers low maintenance requirements, providing peace of mind for manufacturing operations. With regular servicing and maintenance, this equipment can provide years of reliable service, ensuring minimal downtime and maximum productivity.As a leader in providing Industrial Rotary Screw Air Compressors, {} has been at the forefront of innovation and quality in the industry. With a commitment to delivering reliable and efficient compressed air solutions, {} has earned a reputation for excellence among industrial manufacturing companies worldwide. With a wide range of products to meet various industrial needs, {} has become a trusted partner for those seeking to enhance their production capabilities.One of the key factors that set {} apart is its dedication to customer satisfaction. By providing comprehensive support and service, the company ensures that its customers can rely on their Industrial Rotary Screw Air Compressors to perform at the highest level. With a team of experienced professionals, {} is capable of offering tailored solutions to meet the specific requirements of its clients, further enhancing the value of its products.In addition to its commitment to quality and customer satisfaction, {} is also dedicated to environmental responsibility. The Industrial Rotary Screw Air Compressor is designed with energy efficiency in mind, helping to reduce the carbon footprint of manufacturing operations. As sustainability becomes an increasingly important aspect of business operations, {} is proud to contribute to this global initiative while helping its clients achieve their environmental goals.Looking ahead, the demand for Industrial Rotary Screw Air Compressors is expected to continue to grow as industries strive to enhance their efficiency and productivity. With the advancements in technology and manufacturing processes, the need for reliable and efficient compressed air solutions will only become more critical. As a trusted provider of Industrial Rotary Screw Air Compressors, {} is poised to lead the way in meeting these evolving needs and driving the future of industrial manufacturing.In conclusion, the Industrial Rotary Screw Air Compressor has proven to be a vital component in the success of industrial manufacturing operations. With its continuous supply of compressed air, energy efficiency, and low maintenance requirements, this equipment has become the engine of productivity for many companies. As a leading provider of Industrial Rotary Screw Air Compressors, {} continues to play a crucial role in helping industries achieve their production goals while maintaining a focus on quality, customer satisfaction, and environmental responsibility.

Ultimate Guide to Industrial Screw Air Compressors: Everything You Need to Know

[Company Name], a leading manufacturer of industrial equipment, has recently introduced a new and innovative Industrial Screw Air Compressor to its product line. This cutting-edge compressor is designed to meet the increasing demand for reliable and efficient air compression solutions in a wide range of industrial applications.The Industrial Screw Air Compressor is built to deliver high performance and energy efficiency, making it an ideal choice for businesses looking to optimize their operations and reduce their environmental footprint. With a robust and durable design, this compressor is capable of handling the most demanding industrial settings, providing a continuous and reliable source of compressed air.One of the key features of the Industrial Screw Air Compressor is its advanced screw compressor technology, which allows for smooth and quiet operation while delivering consistent air pressure. This technology also ensures minimal energy consumption, resulting in cost savings for businesses in the long run. With a high-efficiency motor and precision engineered components, this compressor is designed to deliver maximum output while minimizing maintenance requirements.In addition to its advanced technology, the Industrial Screw Air Compressor is designed with user-friendliness in mind. The intuitive control panel and user interface make it easy for operators to monitor and adjust the compressor's performance, ensuring optimal operation at all times. Furthermore, the compressor is equipped with safety features to protect both the equipment and the workers using it, offering peace of mind in industrial environments.“We are excited to introduce the Industrial Screw Air Compressor to our product lineup,” said [Company Name]’s CEO. “As a company committed to providing innovative and reliable industrial solutions, we believe that this compressor will make a significant impact in the industry by offering superior performance, energy efficiency, and user-friendly operation.”The Industrial Screw Air Compressor is available in a range of models to suit different industrial needs, from small-scale operations to large manufacturing facilities. With customizable options for capacity, pressure, and additional features, businesses can find the right compressor to meet their specific requirements.As part of [Company Name]'s commitment to customer satisfaction, the Industrial Screw Air Compressor is backed by comprehensive support services. This includes installation assistance, maintenance training, and responsive technical support to ensure that businesses can maximize the performance and longevity of their investment.With a proven track record of delivering high-quality industrial equipment, [Company Name] has established itself as a trusted partner for businesses looking to enhance their operations. The introduction of the Industrial Screw Air Compressor further solidifies [Company Name]'s position as a leader in the industry, providing innovative solutions that drive efficiency and productivity for its customers.The Industrial Screw Air Compressor is now available for purchase, and interested businesses are encouraged to contact [Company Name] for more information about this cutting-edge industrial solution. With its advanced technology, user-friendly design, and comprehensive support services, the Industrial Screw Air Compressor is set to make a significant impact in the industrial sector, delivering reliable and efficient compressed air solutions for a wide range of applications.

High-Quality Screw Compressor Spare Parts for Efficient Repairs

Screw Compressor Spare (SCS), a leading supplier of high-quality spare parts for screw compressors, has been making waves in the industry with their commitment to excellence and customer satisfaction. With their extensive range of products and dedication to innovation, SCS has become a trusted name in the field of compressor spare parts.Established in [year], SCS has quickly carved out a niche for itself in the market by providing top-notch spare parts for screw compressors. Their dedication to quality and customer service has earned them a reputation for reliability and excellence among their clientele. With a team of highly skilled professionals and a state-of-the-art manufacturing facility, SCS is committed to delivering products that meet and exceed the expectations of their customers.One of the key factors that sets SCS apart from its competitors is its diverse range of products. From screws and rotors to bearings and seals, SCS offers a comprehensive selection of spare parts for various types and brands of screw compressors. This extensive range of products allows SCS to cater to the needs of a wide range of customers, from small businesses to large industrial operations.In addition to their wide product range, SCS also prides itself on its commitment to innovation. The company continuously invests in research and development to stay abreast of the latest technological advancements in the industry. This dedication to innovation enables SCS to continuously improve the quality and performance of their products, ensuring that they remain at the forefront of the market.Furthermore, SCS places a strong emphasis on customer satisfaction. The company strives to build long-lasting relationships with its customers by providing exceptional service and support. SCS understands the critical role that screw compressors play in various industrial applications, and they are dedicated to providing reliable and efficient spare parts that keep their customers' operations running smoothly.In recent news, SCS has announced the launch of a new line of screw compressor spare parts that are designed to offer even greater reliability and performance. The new products include advanced components that have been engineered to withstand the rigors of demanding industrial environments. With these new offerings, SCS aims to further solidify its position as a top supplier of spare parts for screw compressors.Additionally, SCS has also expanded its distribution network to better serve its customers. The company has established strategic partnerships with distributors in key regions, allowing them to reach a broader customer base and provide timely support and service to their clients."We are excited to introduce our new line of screw compressor spare parts, which are the result of our ongoing commitment to innovation and excellence," said [Spokesperson name], [Title] at SCS. "These new products have been meticulously designed and tested to ensure that they meet the highest standards of quality and performance. We are confident that they will deliver exceptional value to our customers and help them enhance the efficiency and reliability of their compressor systems."As SCS continues to grow and expand its product offerings, the company remains dedicated to upholding its core values of quality, innovation, and customer satisfaction. With its unwavering commitment to excellence, SCS is well-positioned to continue leading the way in the supply of spare parts for screw compressors for years to come.

Powerful 10 HP Screw Compressor for Your Industrial Needs

10 HP Screw Compressor: A Reliable Solution for Your Compressed Air NeedsIn today's industrial and manufacturing landscape, having a reliable source of compressed air is crucial for powering various tools and equipment. This is where the 10 HP Screw Compressor comes in, offering a dependable and efficient solution for businesses looking to meet their compressed air requirements.{Company Name} is proud to introduce the 10 HP Screw Compressor to its line of industrial equipment. With a strong focus on innovation and quality, {Company Name} has been a trusted name in the industry for providing top-notch machinery and tools for various applications.The 10 HP Screw Compressor is designed to deliver consistent and high-quality compressed air, making it an ideal choice for a wide range of industrial and manufacturing operations. Whether it's for powering pneumatic tools, operating machinery, or even for use in HVAC systems, this compressor is up to the task.One of the key features of the 10 HP Screw Compressor is its energy efficiency. With a focus on reducing energy consumption and operating costs, this compressor is designed to deliver maximum performance while minimizing power requirements. This not only helps businesses save on energy bills but also contributes to a more sustainable and eco-friendly operation.Another standout feature of the 10 HP Screw Compressor is its durability and reliability. Built to withstand the rigors of industrial use, this compressor is constructed using high-quality materials and components, ensuring long-term performance and minimal downtime. This reliability is crucial for businesses that rely on compressed air for their day-to-day operations.Maintenance is also made easy with the 10 HP Screw Compressor, thanks to its user-friendly design and accessible components. This allows for quick and hassle-free servicing, keeping downtime to a minimum and ensuring that the compressor operates at peak efficiency.In addition, {Company Name} offers comprehensive support and service for the 10 HP Screw Compressor, including installation, training, and ongoing maintenance. This ensures that businesses can maximize the performance and lifespan of their compressor, allowing them to focus on their core operations with confidence.The 10 HP Screw Compressor is available in various configurations to suit different application needs, making it a versatile and adaptable solution for businesses of all sizes and industries. Whether it's for a small workshop or a large-scale manufacturing facility, this compressor can be tailored to meet specific compressed air requirements.With a commitment to quality, performance, and customer satisfaction, {Company Name} stands behind the 10 HP Screw Compressor, offering a reliable and cost-effective solution for businesses looking to optimize their compressed air systems.In conclusion, the 10 HP Screw Compressor from {Company Name} is a standout solution for businesses in need of a reliable and efficient source of compressed air. With its energy-efficient design, durability, and comprehensive support, this compressor is a valuable addition to any industrial operation, helping businesses meet their compressed air needs with confidence and peace of mind.

Twin Screw Air Compressors: A Comprehensive Guide for Efficient Industrial Applications

Twin Screw Air Compressor Revolutionizes Compressed Air System IndustryCompressed air is an integral component in various industrial processes, and air compressors are at the heart of compressed air systems. The trouble, however, is that traditional air compressors are often noisy, inefficient, and prone to breakdowns, resulting in production delays and hiked maintenance costs. But thanks to recent advancements in air compressor technology, a new player in the market is set to revolutionize how manufacturers and other industries handle their compressed air needs.Introducing a revolutionary product, the Twin Screw Air Compressor (TSAC), developed by a leading global engineering solutions provider. The company specializes in the design and manufacture of complex engineering systems, with a focus on energy efficiency, productivity, and operational safety. The unrivaled expertise of the company’s engineers went into producing the Twin Screw Air Compressor, a next-generation technology that promises to transform the compressed air industry.So, what makes this particular air compressor so special?First, the TSAC operates much quieter than traditional air compressors, producing minimal noise pollution. This feature, coupled with its low vibration, allows for placement at any location without fear of noise disturbance. As a result, manufacturers can position the compressor closer to their production processes, minimizing air leaks, which can significantly improve energy efficiency and minimize maintenance costs.Second, the TSAC has an energy efficiency rate of up to 98%. This means that it can convert almost all of the electrical energy it utilizes into usable compressed air, delivering significant energy savings compared to traditional reciprocating or rotary air compressors. For industries that consume massive amounts of compressed air, this feature can lead to millions of dollars in energy savings over time.Third, the TSAC's unique oil-injected twin-screw design ensures that there is always a constant supply of compressed air. This feature eliminates the pulsating flow common with traditional air compressors, resulting in a steady stream of compressed air output that can improve production quality and reduce downtime.Fourth, TSAC has a longer service life than other air compressors, thanks to its state-of-the-art construction materials that ensure its longevity. The sound dampening canopy surrounding the air compressor is made of high-quality steel, preventing rust and corrosion. Additionally, the screws are coated in a proprietary material that ensures their abrasion resistance, minimizing wear and tear.Fifth, the TSAC is equipped with an intelligent control system that monitors its performance and adjusts its operations in real-time to maximize efficiency. The advanced monitoring system allows operators to detect problems before they cause any extensive damage, reducing maintenance costs and downtime. The operator-friendly design of the control system also allows for remote installation, monitoring, and control, reducing the need for personnel on-site.In summary, the Twin Screw Air Compressor is a game-changer in the air compressor industry. Its unique features make it more energy-efficient, reliable, and user-friendly than traditional models, leading to significant cost savings and improved production quality. With its state-of-the-art monitoring system and superior construction materials, the TSAC is a valuable investment that can serve industries for decades.

Industry Spotlight: The Advantages of Portable Rotary Screw Air Compressors

As the demand for portable rotary screw air compressors continues to rise, companies are constantly innovating to meet customer needs. One such company, which is well-known in the industry for producing high-quality air compressors, has recently launched a new portable rotary screw air compressor that promises to be a game changer for professionals.This new compressor, which features advanced technology and innovative design, has been designed to provide reliable and efficient performance in even the most demanding work environments. With its compact and lightweight design, it can easily be transported from one job site to another, making it ideal for contractors and other professionals who need to work in different locations.The compressor is powered by a high-performance, energy-efficient motor that delivers the perfect amount of air pressure for a range of applications. Its advanced filtration system ensures that the air is clean and free of contaminants, which is essential for applications where clean air is critical. Additionally, the compressor features a rugged construction that is built to withstand the toughest work conditions, ensuring that it can be relied upon for years to come.One of the standout features of this new portable rotary screw air compressor is its user-friendly control panel. Designed with ease of use in mind, the control panel is intuitive and easy to navigate, allowing even novice users to operate the compressor with ease. From here, users can adjust the air pressure, monitor the oil level, and track the compressor's runtime, among other things.In addition to its advanced features and innovative design, this new compressor is backed by the company's renowned customer service and support. With a strong commitment to customer satisfaction, the company offers comprehensive support, including maintenance, repair, and technical assistance, ensuring that users get the most out of their compressor.According to the company spokesperson, "We are excited to launch this new portable rotary screw air compressor, which reflects our commitment to innovation and quality. We understand that our customers require robust and reliable equipment that can perform even in the most demanding work environments, and we are proud to deliver a product that meets those needs."Experts in the industry have also expressed their enthusiasm about this new compressor, praising its innovative design, advanced features, and use of high-quality materials. They predict that it will quickly become a favorite among professionals in a range of industries, including construction, manufacturing, and more.Overall, this new portable rotary screw air compressor is an impressive addition to the market, offering users an efficient and reliable option for their compressed air needs. With its advanced technology, user-friendly design, and superior performance, it is sure to become a go-to choice for professionals seeking a top-quality compressor that delivers results every time.

Explore Latest Information and Features of Air Compressor: Reviews, Photos, and More

Air compressors have revolutionized various industries, providing compressed air for countless applications. From powering pneumatic tools to operating factories and manufacturing plants, industrial compressor machines have a multitude of uses. With technological advancements, there are numerous air compressors to choose from in the market. In this blog post, we'll delve into everything you need to know about industrial compressor machines.Understanding Industrial Compressor MachinesAn industrial compressor machine is a device that converts power from an electric motor or diesel engine into potential energy stored in pressurized air. Industrial air compressors can be classified into two major types - reciprocating and rotary.Reciprocating compressors work in a similar way to car engines. Pistons inside the compressor cylinder compress air into the storage tank. While these compressors are compact and cost-effective, they are also the noisiest and have higher maintenance requirements.Rotary compressors compress air using rotating screws, lobes, or vanes. These compressors are generally quieter and have lower maintenance requirements than reciprocating compressors. However, they are also more expensive and consume more electricity.Application of Industrial Compressor MachinesIndustrial compressor machines have a multitude of applications in various industries. Some of these applications include:1. Pneumatic Tools - Industrial compressors power a wide range of pneumatic tools such as nail guns, sanders, and painting guns. By providing compressed air, they enable the smooth operation of these tools, increasing productivity in the workplace.2. Oil and Gas - Industrial compressors play a vital role in the oil and gas industry. They are used to extract gas from wells and transport oil and gas through pipelines.3. Manufacturing - Most manufacturing cases require the use of compressed air for various processes such as pressure testing, spray painting, and packaging lines.4. Mining - Compressors are used in mining operations to operate pneumatic drilling equipment and control ventilation.5. Construction - Air compressors power large construction tools such as jackhammers and concrete mixers.Factors to Consider When Choosing Industrial Compressor MachinesWhen it comes to choosing industrial compressor machines, there are several factors to keep in mind. These include:1. Type of compressor - As mentioned earlier, there are two major types of compressors. The first step is to determine which type of compressor best suits your application.2. Required airflow - The amount of compressed air required is an essential consideration. It is critical to choose a compressor that can provide adequate airflow for your application.3. Operating pressure - The operating pressure needed will depend on the application. It is important to select a compressor that can provide the required pressure levels.4. Noise level - Noise pollution is a significant concern when it comes to compressed air. Choose a compressor that operates at an acceptable noise level for your work environment.5. Maintenance requirements - Different compressors have different maintenance requirements. It is important to choose a compressor that you can maintain easily and cost-effectively.ConclusionIndustrial compressor machines are essential in various industries, providing compressed air for various processes. From choosing the right type of compressor to considering the maintenance requirements, there are several factors to keep in mind when choosing a compressor. By understanding industrial compressor machines, determining the right compressor for your application, and maintaining it correctly, you can increase productivity while reducing costs in the long run.

Improve Efficiency and Reduce Costs with a High-Quality Compressed Air System

Title: Leading Industrial Compressed Air System Provider Unveils Cutting-Edge Technology for Enhanced OperationsIntroduction:With the rapid growth of various industries, the demand for efficient industrial compressed air systems has never been higher. Catering to this need, industry-leading company [Company name removed] has emerged as a trusted provider of cutting-edge compressed air solutions. Their dedication to innovation and commitment to customer satisfaction position them at the forefront of the market. In this article, we explore [Company name removed]'s latest advancements in compressed air systems, along with the key features and benefits they offer.Paragraph 1:[Company name removed] is renowned for its state-of-the-art industrial compressed air systems, specially designed to cater to the diverse needs of the industry. The company's astute understanding of customer requirements, coupled with their commitment to technological advancements, propels them to the forefront of the market.Paragraph 2:The latest addition to [Company name removed]'s impressive lineup is the revolutionary XYZ series - a cutting-edge compressed air system that sets new standards for efficiency and reliability. Built upon years of research and development, the XYZ series surpasses industry benchmarks and addresses the challenges faced by businesses across multiple sectors.Paragraph 3:At the core of the XYZ series lies an innovative compressor unit with advanced variable speed technology. This technology enables the compressor to automatically adjust its speed based on the actual compressed air demand, resulting in significant energy savings. Furthermore, the XYZ series boasts an intelligent control system that ensures maximum operational efficiency, reducing idle time and minimizing maintenance costs.Paragraph 4:One of the key features of the XYZ series is its exceptional reliability. Built with high-quality materials and components, the system offers unmatched durability and a prolonged lifespan. Additionally, the XYZ series incorporates advanced filtration technology, providing clean and high-quality compressed air for critical applications, ensuring product safety and efficiency.Paragraph 5:In an effort to contribute to a greener environment, [Company name removed] has incorporated eco-friendly features into the XYZ series. The system boasts a high-efficiency motor that helps lower carbon emissions and a noise reduction system that enhances the working environment for employees. With its sustainable design, the XYZ series aligns perfectly with the company's commitment to environmentally conscious solutions.Paragraph 6:Recognizing the importance of after-sales support, [Company name removed] offers a comprehensive maintenance program to ensure consistent performance of their compressed air systems. Skilled technicians provide regular inspections, preventive maintenance, and emergency support, ensuring minimal downtime for businesses.Paragraph 7:In addition to driving operational efficiency, the XYZ series emphasizes ease of use. The user-friendly interface and intuitive controls streamline operations and decrease the learning curve for operators. This feature is particularly beneficial for businesses with diverse workforce backgrounds, ensuring smooth integration into existing operations.Paragraph 8:Customer testimonials and feedback offer considerable support for [Company name removed]'s commitment to customer satisfaction. Case studies highlight how the XYZ series has revolutionized operations, offering significant cost savings, increased productivity, and reduced maintenance interventions.Conclusion:[Company name removed]'s XYZ series showcases their unwavering commitment to providing state-of-the-art compressed air solutions that cater to the varying needs of industries worldwide. Through impeccable research and design, the company has developed a technologically advanced system that delivers enhanced efficiency, reliability, and eco-friendliness. As businesses continue to prioritize operational excellence, [Company name removed] stands poised to play a pivotal role in their success with their cutting-edge compressed air solutions.

High-Quality Small Screw Air Compressor for Sale

Small Screw Air Compressor Exceeds Expectations in Performance and EfficiencyIn the world of industrial machinery and manufacturing, efficiency and performance are key factors for success. One company that understands this well is {Company Name}, a leading manufacturer of small screw air compressors. With a commitment to innovation and quality, {Company Name} has been exceeding the expectations of their customers with their latest small screw air compressor, which has been making waves in the industry.The small screw air compressor designed and manufactured by {Company Name} has been a game-changer for many businesses, both large and small. Its compact size and powerful performance make it an ideal choice for a wide range of applications, from automotive workshops to small manufacturing operations. The compressor's cutting-edge technology and design have set a new standard in the industry, providing customers with a reliable, energy-efficient, and cost-effective solution for their compressed air needs.One of the key features that sets the small screw air compressor apart from its competitors is its outstanding performance. Despite its small size, it delivers high air output and pressure, allowing users to power a variety of pneumatic tools and equipment with ease. This high performance is made possible by the compressor's advanced screw design, which ensures smooth and efficient air compression without compromising on quality.Furthermore, {Company Name}'s small screw air compressor is also praised for its impressive energy efficiency. By incorporating advanced energy-saving technologies, such as variable speed drives and innovative cooling systems, the compressor is able to significantly reduce energy consumption, resulting in lower operating costs for businesses. This has made it a popular choice among environmentally conscious customers who are looking to reduce their carbon footprint and energy bills.Another standout feature of the small screw air compressor is its durability and reliability. Built with high-quality materials and precision engineering, the compressor is designed to withstand the rigors of continuous use in demanding industrial environments. This level of reliability gives customers the peace of mind that their operations will not be disrupted by unexpected equipment failures, allowing them to focus on increasing productivity and profitability.{Company Name} takes great pride in its commitment to customer satisfaction and has gone above and beyond to provide exceptional support and service for its small screw air compressor. From installation and ongoing maintenance to troubleshooting and repairs, the company's team of experienced technicians is dedicated to ensuring that customers get the most out of their investment. This level of support has earned {Company Name} a strong reputation for customer care and has resulted in long-lasting relationships with many satisfied clients.As the demand for high-quality compressed air solutions continues to grow across various industries, {Company Name} remains at the forefront of innovation and excellence. With its small screw air compressor exceeding expectations in performance, energy efficiency, and reliability, the company is well-positioned to meet the evolving needs of its customers and maintain its status as a leader in the industry.In conclusion, {Company Name}'s small screw air compressor has proven to be a game-changing solution for businesses seeking efficient and reliable compressed air. With its high performance, energy efficiency, and exceptional support, the compressor has earned the trust and satisfaction of many customers. As the industry continues to evolve, {Company Name} remains dedicated to pushing the boundaries of innovation and setting new standards for compressed air technology.

High-Quality Compressor Desiccant Dryer: A Must-Have for Your Industrial Applications

Compressor Desiccant Dryer: A Game Changer in Industrial Drying TechnologyIn today's fast-paced industrial landscape, efficiency and reliability are key factors in maintaining a competitive edge. With the increasing demand for high-quality compressed air, it has become essential for industries to invest in advanced drying technologies to ensure optimal performance of their pneumatic equipment. This is where the Compressor Desiccant Dryer comes into play. Developed by a leading manufacturer in the field of air treatment solutions, this cutting-edge dryer is designed to deliver superior drying performance, while offering a range of innovative features that set it apart from traditional drying systems.The Compressor Desiccant Dryer utilizes a dual-tower design, allowing for continuous drying operations without any interruptions. This ensures a consistent supply of dry air, which is crucial for preventing corrosion and contamination in pneumatic systems. In addition, the dryer is equipped with high-efficiency desiccant material that effectively removes moisture from the compressed air, resulting in enhanced air quality and extended equipment lifespan.One of the key advantages of the Compressor Desiccant Dryer is its advanced control system, which enables precise monitoring and adjustment of drying parameters. This level of automation eliminates the need for manual intervention, streamlining the drying process and reducing the risk of human error. As a result, users can enjoy peace of mind knowing that their compressed air supply is consistently maintained at optimal moisture levels.Moreover, this state-of-the-art dryer is engineered for energy efficiency, helping industries minimize operational costs and reduce their environmental footprint. By incorporating smart technologies such as variable speed drives and heat recovery systems, the Compressor Desiccant Dryer maximizes energy utilization and lowers overall power consumption. This not only translates to financial savings for businesses but also contributes to sustainability efforts.The reliability of the Compressor Desiccant Dryer is further underscored by its robust construction and adherence to stringent quality standards. Built to withstand demanding industrial environments, the dryer is engineered with durable components and precision engineering, ensuring long-term performance and minimal maintenance requirements. This durability is a testament to the manufacturer's commitment to delivering products that are built to last.In line with the company’s dedication to customer satisfaction, the Compressor Desiccant Dryer is backed by comprehensive technical support and after-sales services. From installation and commissioning to ongoing maintenance and troubleshooting, the manufacturer provides a full suite of support offerings to ensure that users get the most out of their investment. This customer-centric approach reflects the company's ethos of delivering value beyond the product itself.With its innovative features, advanced capabilities, and unwavering commitment to quality, the Compressor Desiccant Dryer has quickly become a game changer in the realm of industrial drying technology. Its ability to deliver consistently dry air, coupled with energy efficiency and reliable performance, makes it an indispensable asset for a wide range of industries, from manufacturing and automotive to food and beverage.As industries continue to prioritize the optimization of their compressed air systems, the Compressor Desiccant Dryer stands out as a solution that not only meets but exceeds the evolving needs of modern businesses. With its cutting-edge technology and customer-oriented approach, it is poised to set new benchmarks in the realm of air treatment solutions, solidifying its position as a leading choice for industrial drying requirements.