Understanding the benefits of high pressure screw compressors

By:Admin

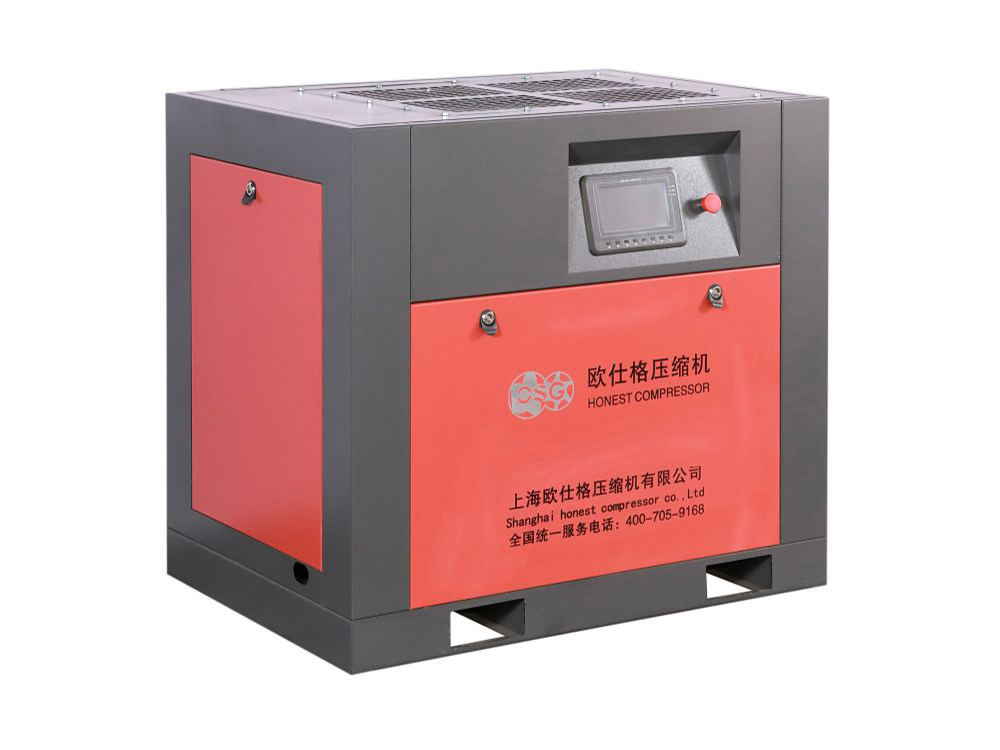

High Pressure Screw Compressor Revolutionizes Industrial Air Supply

A high-pressure screw compressor has been developed by a leading manufacturer to deliver more efficient, reliable and durable performance, transforming industrial air supply and delivering significant cost savings.

This new solution, available without the use of oil, is set to provide a game-changing alternative for businesses of all sizes, as it offers consistent high-pressure compressed air in applications that demand enhanced equipment performance. It can be used in various industries including, but not limited to, steel, cement, electronics, and automobiles.

High-pressure screw compressors are necessary to supply compressed air for various processes and applications where larger volumes of compressed air are required at higher pressures than can be provided by traditional low-pressure systems. Compressed air is used as an energy source, for pneumatic tools, and for operating production equipment, so the reliability and efficiency of the compressor have a considerable impact on productivity and profitability.

This new compressor uses an innovative design to deliver a superior air supply, with advanced technology to support the maximum possible energy efficiency under any operating condition and without loss of performance. It utilizes a twin-screw rotary design, which is well-suited for high output, high-pressure applications.

Combining advanced technological innovation with a dependable product design, and a strong focus on optimizing efficiency, the product offers a compelling and unique value proposition.

The new high-pressure screw compressor is available in a wide range of sizes and configurations, incorporating the latest technological advancements to deliver the highest level of energy efficiency and reliability in various applications.

The use of oil-free screw compressors ensures that businesses can minimize the risk of contamination in their production environment, ensuring consistent performance and minimizing the need for maintenance. In addition, oil-free models facilitate a more eco-friendly approach to powering industrial equipment, with significantly lower carbon emissions during operation.

At its core, the new high-pressure screw compressor is designed to provide optimal performance, delivering increased productivity, end-product quality, and reduced maintenance costs. It is highly efficient, with a low noise level, and designed to support energy-saving operation under heavy loads while reducing downtime.

“Over the years, we have seen considerable demand for high-pressure compressed air systems that are both reliable and cost-effective,” said the company spokesperson. “This new solution provides a unique and highly competitive alternative that meets the needs of businesses both large and small, across multiple industries. We believe this product is set to transform the way companies approach their compressed air needs, delivering instant benefits to the bottom line.”

In conclusion, the deployment of this innovative new product represents a major step forward for businesses looking to improve their compressed air supply while reducing costs and supporting sustainability objectives. This product represents the latest in a long line of technological innovations by one of the world's leading manufacturers, and it is poised to make a significant impact in various sectors. Businesses that are looking to improve the efficiency and reliability of their compressed air systems should naturally look to this new high-pressure screw compressor as a game-changing solution.

Company News & Blog

Leading Air Compressor Manufacturer in Ahmedabad, India: Top Quality Products & Services Available

As the demand for air compressors rises globally, Real Air Compressor, a leading air compressor manufacturer based in Ahmedabad, India, is making a significant impact in the industry. Established in 1995, Real Air Compressor has built a reputation for producing high-quality and reliable air compressors for various applications, including industrial, commercial, and residential use.While the company started manufacturing single-stage air compressors, its commitment to quality and customer satisfaction has helped it expand its product range. Today, the company produces a wide range of air compressors, including two-stage air compressors, lubricated and oil-free air compressors, reciprocating air compressors, and screw air compressors, among others.Real Air Compressor places a high value on innovation and technology, continually updating its manufacturing processes and investing in the latest technology. The company's engineering team comprises experienced professionals who work with the latest software and design tools to develop efficient, reliable, and durable air compressors that meet the diverse needs of its customers.The company's dedication to quality has also earned it global recognition, with its air compressors exported to various countries worldwide. Real Air Compressor adheres to strict quality control measures, using high-grade materials to manufacture its machines and testing them thoroughly before releasing them to the market. This approach has helped the company build a loyal customer base, with many of its clients returning for repeat purchases and referring others to the company.One aspect that sets Real Air Compressor apart from its competitors is its after-sales service. The company has a team of skilled technicians who provide comprehensive installation, maintenance, and repair services to its clients. This support ensures that the customers' air compressors continue to operate efficiently throughout their lifespan, minimizing downtime and reducing maintenance costs.To expand its reach and provide better services to its customers, Real Air Compressor has established a global network of distributors. This distribution network enables the company to reach customers in different parts of the world, providing them with high-quality air compressors and related services quickly and efficiently.In recent years, Real Air Compressor has invested heavily in research and development, seeking to develop more energy-efficient air compressors that meet environmental standards. The company recognizes the need to reduce the carbon footprint of its machines and develop more sustainable solutions for its customers. This commitment to sustainability has seen the company develop air compressors that reduce energy consumption and noise pollution, making them more environmentally friendly.As the world's demand for air compressors grows, Real Air Compressor is poised to continue making a significant impact in the industry. The company's commitment to quality, innovation, and customer satisfaction is second to none, making it one of the most reputable air compressor manufacturers globally. With its extensive product range, global distribution network, and world-class after-sales services, Real Air Compressor has positioned itself as a leader in the air compressor industry, setting the benchmark for others to follow.

Discover the Advantages of Industrial Oil Free Air Compressors for Efficient Operations

[Industrial Oil-Free Air Compressor] Revolutionizing the Manufacturing Industry[City, Date] - In today's manufacturing sector, efficiency, sustainability, and cleanliness are of paramount importance. With the increasing awareness of environmental concerns and the need for reducing carbon footprints, industries are embracing innovative technologies to enhance their productivity while minimizing their impact on the environment. One such groundbreaking solution that has caught the attention of manufacturers worldwide is the Industrial Oil-Free Air Compressor, designed and developed by a leading industry player.A pioneer in air compressor technology, this company has revolutionized the manufacturing industry with its state-of-the-art oil-free air compressor. Combining advanced engineering techniques with extensive research and development, they have created a compressor that offers numerous benefits to manufacturing facilities, making it an indispensable asset within industrial settings.The Industrial Oil-Free Air Compressor serves as an energy-efficient alternative to traditional oil-lubricated compressors. By eliminating the need for oil, it delivers compressed air that is entirely free from any oil contaminants. This ensures that the air meets the highest standards of purity, making it particularly suitable for industries that demand clean air, such as pharmaceuticals, food and beverages, electronics, and automotive manufacturing.Featuring cutting-edge technology, this air compressor guarantees exceptional performance, reduced maintenance costs, and minimized downtime. The advanced design utilizes a series of precision-engineered components to achieve remarkable efficiency, resulting in significant energy savings for the company. By avoiding the use of oil, manufacturers can eliminate the associated costs of oil procurement, disposal, and maintenance, leading to substantial financial savings.Moreover, the Industrial Oil-Free Air Compressor exceeds regulatory standards set by environmental agencies worldwide. With a focus on sustainability, the company has created a compressor that significantly reduces carbon emissions, contributing to a cleaner and greener environment. By eliminating oil, which is a major source of air pollution, the compressor has achieved an impressive environmental footprint. This makes it an excellent choice for companies aiming to fulfill their corporate social responsibility by adopting eco-friendly practices.The oil-free design also ensures that the compressor operates quietly, without compromising on performance. This feature is particularly valuable for manufacturing units located in urban areas or those situated in close proximity to residential areas. The reduced noise levels promote a healthier, more comfortable working environment for employees while enhancing the overall harmony within the community.In addition to these advantages, the Industrial Oil-Free Air Compressor offers unmatched reliability and durability. With rigorous quality control and meticulous testing procedures, the company guarantees that each compressor leaving their factory is of the highest standard. This reliability ensures minimal disruptions to the manufacturing process, safeguarding productivity and reducing costly downtime.With an unwavering commitment to customer satisfaction, the company not only provides cutting-edge technology but also offers exceptional customer service. A team of highly skilled engineers and technicians provides prompt assistance, ensuring that each client receives personalized support tailored to their unique requirements.As the industrial landscape continues to evolve, manufacturers must adapt to emerging trends and technologies to stay ahead in the competitive market. The Industrial Oil-Free Air Compressor represents the future of compressed air solutions, providing manufacturers with the means to improve productivity, reduce costs, and align with sustainable practices. With an emphasis on quality, efficiency, and environmental consciousness, this compressor is poised to transform the manufacturing industry, offering businesses a reliable and dynamic solution for their compressed air needs.About [Company]:[Company] is a pioneering force in the air compressor industry, specializing in innovative and sustainable compressed air solutions. With a global presence and a commitment to excellence, [Company] has established itself as a trusted provider of state-of-the-art compressors, catering to a diverse range of industries. By combining cutting-edge technology, extensive research, and unparalleled customer service, [Company] continues to shape the future of compressed air solutions worldwide.For media inquiries, please contact:[Contact Information]###

Find the Best Air Compressor Suppliers in the UK - Get Free Quotes

Looking for a reliable Industrial Heavy Duty Air Compressor? Look no further than the leading air compressor suppliers in the UK. With so many options available, it can be overwhelming to choose the right air compressor for your needs. Luckily, our suppliers offer free quotes and advice to help you make the right choice.First, let's take a look at what makes an air compressor "heavy duty." Industrial heavy duty air compressors are specifically designed to handle tough jobs in large, commercial settings. These compressors are built for constant use and are known for their durability and efficiency.When comparing air compressor suppliers, it's important to consider their experience and reputation in the industry. Our suppliers have years of experience providing top-quality air compressors to a range of industries, including construction, automotive, and manufacturing.Another factor to consider when choosing an air compressor is the type of compressor you need. Our suppliers offer a range of compressor types, including rotary screw compressors, reciprocating compressors, and centrifugal compressors. Each type has its own unique advantages and disadvantages, so it's important to consult with our suppliers to determine which type is best for your specific needs.One of the most important factors to consider when choosing an air compressor is its overall performance. Industrial heavy duty air compressors are designed to provide high levels of performance and efficiency, allowing you to complete your projects with ease. Look for air compressors with high CFM (cubic feet per minute) and PSI (pounds per square inch) ratings to ensure optimal performance.When it comes to choosing an air compressor, it's also important to consider your budget. Our suppliers offer a range of affordable options, so you can find an air compressor that fits your budget without sacrificing on quality or performance.In conclusion, if you're in need of a reliable Industrial Heavy Duty Air Compressor, turn to the UK's leading air compressor suppliers. With their free quotes, expert advice, and top-quality products, you can feel confident in your choice and get back to work with ease.

Understanding the benefits of high pressure screw compressors

release.High Pressure Screw Compressor Revolutionizes Industrial Air SupplyA high-pressure screw compressor has been developed by a leading manufacturer to deliver more efficient, reliable and durable performance, transforming industrial air supply and delivering significant cost savings.This new solution, available without the use of oil, is set to provide a game-changing alternative for businesses of all sizes, as it offers consistent high-pressure compressed air in applications that demand enhanced equipment performance. It can be used in various industries including, but not limited to, steel, cement, electronics, and automobiles.High-pressure screw compressors are necessary to supply compressed air for various processes and applications where larger volumes of compressed air are required at higher pressures than can be provided by traditional low-pressure systems. Compressed air is used as an energy source, for pneumatic tools, and for operating production equipment, so the reliability and efficiency of the compressor have a considerable impact on productivity and profitability.This new compressor uses an innovative design to deliver a superior air supply, with advanced technology to support the maximum possible energy efficiency under any operating condition and without loss of performance. It utilizes a twin-screw rotary design, which is well-suited for high output, high-pressure applications.Combining advanced technological innovation with a dependable product design, and a strong focus on optimizing efficiency, the product offers a compelling and unique value proposition.The new high-pressure screw compressor is available in a wide range of sizes and configurations, incorporating the latest technological advancements to deliver the highest level of energy efficiency and reliability in various applications.The use of oil-free screw compressors ensures that businesses can minimize the risk of contamination in their production environment, ensuring consistent performance and minimizing the need for maintenance. In addition, oil-free models facilitate a more eco-friendly approach to powering industrial equipment, with significantly lower carbon emissions during operation.At its core, the new high-pressure screw compressor is designed to provide optimal performance, delivering increased productivity, end-product quality, and reduced maintenance costs. It is highly efficient, with a low noise level, and designed to support energy-saving operation under heavy loads while reducing downtime.“Over the years, we have seen considerable demand for high-pressure compressed air systems that are both reliable and cost-effective,” said the company spokesperson. “This new solution provides a unique and highly competitive alternative that meets the needs of businesses both large and small, across multiple industries. We believe this product is set to transform the way companies approach their compressed air needs, delivering instant benefits to the bottom line.”In conclusion, the deployment of this innovative new product represents a major step forward for businesses looking to improve their compressed air supply while reducing costs and supporting sustainability objectives. This product represents the latest in a long line of technological innovations by one of the world's leading manufacturers, and it is poised to make a significant impact in various sectors. Businesses that are looking to improve the efficiency and reliability of their compressed air systems should naturally look to this new high-pressure screw compressor as a game-changing solution.

Revolutionary Air-Purifying Technology Uses Desiccants to Combat Moisture and Odor

[Company Name] Revolutionizes Air Desiccant Technology for Enhanced Air Quality[date][City, State] - [Company Name], a leading provider of innovative air quality solutions, is set to transform the industry with its revolutionary Air Desiccant. This advanced technology not only removes excess moisture from the air but also eliminates harmful pollutants, creating a healthier and more comfortable indoor environment for all.In recent years, the issue of indoor air pollution has gained significant attention as it poses a severe risk to public health. Research has shown that indoor air can be up to five times more polluted than outdoor air, making it essential to find effective solutions to combat this problem. [Company Name] has taken up this challenge and developed a cutting-edge Air Desiccant capable of improving air quality in any indoor setting.Traditionally, the primary function of desiccants has been to remove moisture from the air to prevent the growth of mold and mildew. However, [Company Name]'s Air Desiccant goes beyond that by incorporating an innovative filtration system designed to capture and eliminate harmful pollutants, such as dust, pollen, pet dander, and volatile organic compounds (VOCs).The secret behind [Company Name]'s Air Desiccant lies in its advanced filtration technology. Utilizing a multi-stage filtration process, it effectively captures particles as small as 0.3 microns, ensuring that even the tiniest pollutants are trapped. In addition, the Air Desiccant features an activated carbon filter that absorbs and neutralizes odors, leaving the air fresh and clean.One of the key advantages of [Company Name]'s Air Desiccant is its ease of use. Designed for hassle-free operation, it can be effortlessly incorporated into any residential or commercial setting. The compact and lightweight design allows for easy installation, and the intuitive control panel ensures a user-friendly experience. With minimal maintenance requirements, the Air Desiccant offers a truly hassle-free solution for improving air quality.Moreover, the Air Desiccant's intelligent sensor technology automatically adjusts the fan speed and humidity levels to maintain an optimal environment. This feature not only ensures maximum efficiency but also saves on energy consumption, making it an environmentally friendly choice.[Company Name]'s commitment to innovation and product quality is evident in its meticulous manufacturing process. Each Air Desiccant undergoes rigorous quality checks to ensure unparalleled performance and longevity. The company's dedication to customer satisfaction is further demonstrated by its comprehensive warranty and excellent after-sales service.With indoor air quality becoming an increasingly significant concern, [Company Name]'s Air Desiccant is set to disrupt the market and become an industry leader in air purification. Whether it's a residential home, office space, or a healthcare facility, this groundbreaking technology offers a solution to improve the air we breathe, promoting better health and well-being for all occupants.In conclusion, [Company Name] has introduced a game-changing Air Desiccant that combines moisture removal with advanced air purification capabilities. By effectively capturing and eliminating pollutants, this innovative solution has the potential to revolutionize indoor air quality. With its user-friendly design and energy-efficient features, it promises to be a game-changer in the industry. As [Company Name] continues to push boundaries and redefine air quality standards, the future looks bright for cleaner, healthier indoor environments.

Efficient Desiccant Air Dryer for your Air Compression System - Explore now!

When it comes to air compression systems, a crucial component is the air dryer. Moisture in compressed air can cause damage to equipment, decrease efficiency, and lead to costly downtime. That's where desiccant air dryers come in - they effectively remove moisture from compressed air through a process that involves using a desiccant material to absorb the moisture.While standard desiccant air dryers are effective, they may not be the best option for every air compression system. In some cases, a heated desiccant air dryer may be a better choice. In this blog, we'll explore the benefits of heated desiccant air dryers and why they may be the right choice for your air compression system.First things first - what is a heated desiccant air dryer? As the name suggests, these air dryers use heat to regenerate the desiccant material. In a standard desiccant air dryer, the desiccant material becomes saturated with moisture over time and must be regenerated. This is typically done by depressurizing the system and allowing the desiccant to release the moisture into the atmosphere. With a heated desiccant air dryer, the desiccant is heated to release the moisture, allowing it to be used again.So why choose a heated desiccant air dryer over a standard desiccant air dryer? The main advantage is increased efficiency. When a standard desiccant air dryer regenerates its desiccant material, it requires a significant amount of energy to depressurize the system and release the moisture. With a heated desiccant air dryer, the heat is used to regenerate the desiccant, reducing the amount of energy required. This can lead to lower operating costs and increased efficiency.Another advantage of heated desiccant air dryers is their ability to handle variable inlet temperatures and flow rates. In some air compression systems, the inlet temperature and flow rate can fluctuate, which can affect the performance of a standard desiccant air dryer. Heated desiccant air dryers, on the other hand, are designed to handle these fluctuations, ensuring reliable performance in a variety of conditions.It's also worth noting that heated desiccant air dryers are available in a range of sizes and configurations, making them a versatile option for a variety of air compression systems. Whether you need a small unit for a portable compressor or a larger unit for an industrial system, there's a heated desiccant air dryer that can meet your needs.In conclusion, if you're in the market for an air dryer for your compression system, a heated desiccant air dryer may be the way to go. With increased efficiency, reliable performance in varying conditions, and a range of sizes and configurations available, a heated desiccant air dryer offers numerous benefits over a standard desiccant air dryer. Contact us today to learn more about our selection of heated desiccant air dryers and find the perfect solution for your air compression system.

Discover Industrial Air Compressors and Related Products on Ferret.com.au

Industrial air compressors are critical components of most production facilities all over the world. They are used to power a host of industrial applications such as pneumatic tools, air-driven machinery, and spray painting systems.Industrial air compressors come in different types and sizes, but one of the most popular today is the industrial oil-free air compressor. This type of compressor is widely used in facilities that require clean and pure compressed air for processes such as food and beverage production, pharmaceutical manufacturing, and electronics manufacturing.Industrial oil-free air compressors are designed to provide clean, dry, and oil-free compressed air. These compressors are fitted with high-efficiency filters and separators that remove moisture, oil, and other contaminants from the compressed air stream. What makes them unique is their ability to deliver clean and oil-free compressed air, which is critical for processes that require sterile and contamination-free environments.Industrial oil-free air compressors have several advantages over traditional oil-lubricated compressors. Here are a few of them:1. Enhanced air qualityThe main benefit of industrial oil-free air compressors is that they deliver clean, oil-free compressed air. This air is free from pollutants and contaminants, making it ideal for applications that require a sterile and contaminant-free environment. With an industrial oil-free air compressor, you can be confident that the compressed air supply in your facility is of the highest quality.2. Reduced maintenance costsOil-lubricated compressors require regular maintenance to ensure that they function optimally. Maintenance involves regular oil changes, filter replacements, and lubrication of moving parts. With industrial oil-free air compressors, however, there is no need for oil changes and lubrication, which significantly reduces maintenance costs. This also means that there is no risk of oil leaks and spills, which can cause environmental damage and pose a safety hazard.3. Increased energy efficiencyIndustrial oil-free air compressors are designed to deliver optimal performance while consuming less energy. They are fitted with energy-efficient motors and advanced control systems that ensure that they operate at peak efficiency. This translates to lower energy bills, which can significantly reduce operational costs in the long run.4. Longer lifespanIndustrial oil-free air compressors have a longer lifespan than traditional oil-lubricated compressors. This is because they are designed to operate without oil, which reduces wear and tear on the moving parts. This means that you can get more years of service from an industrial oil-free air compressor, making it a cost-effective investment for your facility.In conclusion, industrial oil-free air compressors are a critical component of modern industrial facilities. They offer several advantages over traditional oil-lubricated compressors, including enhanced air quality, reduced maintenance costs, increased energy efficiency, and longer lifespan. With the right industrial oil-free air compressor, you can be confident that your facility is running at maximum efficiency and productivity.

Top Features and Benefits of Fixed Speed Air Compressors

Title: Revolutionary Fixed Speed Air Compressor: A Game-Changer in the IndustryIntroduction (100 words):The air compressor industry has witnessed a groundbreaking development with the introduction of a highly advanced Fixed Speed Air Compressor by a leading industry player. This cutting-edge technology promises to revolutionize the market and redefine efficiency standards. With a focus on meeting the diverse needs of industrial operations, this compressor combines state-of-the-art engineering with an unwavering commitment to reliability and performance. Let us delve into the key features and advantages of this exceptional product, created to address the evolving demands of the rapidly growing industrial sector.Major Advancements in Fixed Speed Air Compressor Technology (200 words):The new Fixed Speed Air Compressor offers an array of significant advancements that make it stand out in the market. Equipped with advanced motor technology, this compressor delivers uninterrupted compressed air supply, ensuring high productivity levels by minimizing downtime. The efficient and robust motor operates with minimum vibration and noise, ensuring a smooth and quiet working environment.The compressor also incorporates smart control technology that enables users to monitor, manage, and adjust the air output and pressure according to specific requirements. This feature maximizes energy efficiency and reduces operating costs, making the Fixed Speed Air Compressor an environmentally-friendly choice for businesses.The intelligent and user-friendly control panel facilitates easy programming and customization, allowing operators to monitor critical parameters such as temperature, oil level, and service intervals. Furthermore, the compressor is equipped with advanced safety features that protect against voltage spikes, overloads, and other potential risks.Applications and Market Potential (200 words):The Fixed Speed Air Compressor is designed to cater to diverse industrial applications, spanning automotive manufacturing, oil and gas, construction, pharmaceuticals, and more. Its high-performance capabilities, coupled with its reliability, make it an ideal choice for businesses looking to enhance productivity and reduce operational costs.The automotive sector, in particular, will benefit from this compressor’s ability to generate a steady stream of compressed air, meeting the rigorous demands of manufacturing, assembly, and paint spraying processes. Similarly, the oil and gas industry will witness significant improvements in drilling operations, wellhead maintenance, and pipeline maintenance due to the compressor’s continuous, efficient air supply.The construction industry will find the Fixed Speed Air Compressor invaluable for powering pneumatic tools, cement blending, and sandblasting operations. Additionally, the pharmaceutical sector can rely on this compressor for sensitive air supply requirements, such as cleanroom environments or pneumatic control systems.Company Overview (200 words):The manufacturer behind this cutting-edge Fixed Speed Air Compressor is a globally renowned company with a rich history of delivering innovative solutions in the air compressor industry. With decades of experience, the company has earned a reputation for its commitment to quality, engineering excellence, and customer satisfaction.Their extensive research and development efforts have resulted in the creation of this state-of-the-art air compressor that surpasses industry standards. By integrating feedback from customers and understanding the evolving needs of different sectors, the company has successfully developed a product that meets varying demands while prioritizing performance, sustainability, and cost-efficiency.Conclusion (100 words):The introduction of the Fixed Speed Air Compressor represents a significant milestone in the air compressor industry. Its advanced technology, unmatched reliability, and exceptional performance make it an invaluable asset to various industrial sectors. From automotive manufacturing to oil and gas operations, this compressor caters to a wide range of applications, enhancing productivity while minimizing environmental impact.As industries strive for improved efficiency and performance, the Fixed Speed Air Compressor serves as a game-changer, setting new benchmarks in the industry. With its innovative features and the reputation of the renowned manufacturer, this compressor is poised to shape the future of compressed air applications in numerous sectors and revolutionize the way businesses operate.

Efficient Methane Gas Screw Compressors with Variable Speed Drive Technology

Oil-lubricated gas screw compressors are crucial components of many different industrial applications. They can be used for a wide variety of purposes, including manufacturing, mining, and energy production. However, not all oil-lubricated gas screw compressors are created equal. Some are designed with specific applications in mind, and the Atlas Copco Taiwan GG-Series is one of them.The GG-Series of gas screw compressors is designed specifically for the compression of methane and biomethane gas. These gases are used in various industrial and energy production applications, and compressing them requires a compressor that is both efficient and durable. The Atlas Copco GG-Series of compressors is designed to meet these exacting requirements.One of the key features of the GG-Series is its Variable Speed Drive (VSD) technology. This technology allows the compressor to adjust its speed and output, depending on the needs of the application. This means that the compressor can operate at maximum efficiency, even when the demand for compressed gas is fluctuating. As a result, the GG-Series is able to provide consistent, reliable performance while minimizing energy consumption and operating costs.Another important feature of the GG-Series is its oil-lubricated design. Unlike some gas compressors that are oil-less, the GG-Series is designed to use oil as a lubricant. This oil helps to reduce friction and wear on the compressor's moving parts, which in turn reduces maintenance requirements and extends the compressor's lifespan.Of course, there are some drawbacks to using an oil-lubricated compressor, such as the need to change the oil and filter regularly. However, for many applications, the benefits of using an oil-lubricated compressor far outweigh the drawbacks. For example, in high-pressure applications, an oil-lubricated compressor can provide a more consistent output than an oil-less compressor, which may experience pressure fluctuations due to its lack of lubrication.In addition to its VSD and oil-lubricated design, the GG-Series also incorporates a number of other features designed to improve performance and reliability. For example, the compressor's advanced control system provides real-time monitoring and diagnostics, allowing operators to optimize performance and troubleshoot problems quickly. The compressor's advanced filtration system also helps to remove impurities and contaminants from the gas stream, improving the quality of the compressed gas and reducing the risk of equipment failure.All of these features make the Atlas Copco Taiwan GG-Series gas screw compressor an excellent choice for applications requiring the compression of methane and biomethane gas. Whether you're in the energy production industry, the manufacturing industry, or any other industry that requires compressed gas, the GG-Series offers the reliability, efficiency, and durability you need to get the job done.In conclusion, oil-lubricated gas screw compressors like the Atlas Copco Taiwan GG-Series are essential components of many industrial and energy production applications. With their Variable Speed Drive technology, oil lubrication, and advanced control systems, the GG-Series compressors are specially designed for the compression of methane and biomethane gas, delivering exceptional performance, reliability, and efficiency while minimizing energy consumption and operating costs. So if you're looking for a compressor that can help you achieve your goals while keeping your costs under control, the Atlas Copco Taiwan GG-Series is an excellent choice.

Best Air Compressors for Garage Use - Maintenance/Repairs - Car Talk Community

In today's fast-paced world, our cars are our lifelines. They take us from point A to point B with ease and speed, making our lives more convenient than ever before. However, owning a car also brings some responsibilities. Keeping your car well maintained is essential to ensure its long-term functionality. One of the crucial requirements for maintaining your car is an air compressor. From inflating tires to powering air tools, air compressors play an essential role in keeping your car in optimal condition.That being said, finding the right air compressor can be a daunting task. There are so many brands and types of air compressors available in the market, each with its unique features and specifications. However, one of the most critical factors to consider while selecting an air compressor is its durability. After all, you don't want to invest in a device you will have to replace every other year.One of the top-rated air compressors for car maintenance and repairs is a product from a well-known brand in the industry. However, to avoid any bias, this article will not mention the brand name. This air compressor is known for its sturdy build and longevity. It is designed to withstand extended usage and harsh environments, making it ideal for use in a garage.Another advantage of this air compressor is that it can be easily connected to a standard electrical outlet. This eliminates the need for any special electrical wiring, making it an easy and hassle-free addition to your garage. Additionally, it is designed to provide optimal performance for its users while ensuring that your electricity bills remain manageable.Another feature that makes this air compressor an excellent choice for car owners is that it is multi-functional. This means that you can use it for various purposes such as inflating tires, powering pneumatic tools, and other tasks that require compressed air. This makes it an added convenience for car owners, as you no longer have to invest in separate devices for individual tasks.More importantly, this air compressor requires minimal maintenance. It is designed to be a hassle-free addition to your garage, and you don't have to worry about maintaining it regularly. In doing so, this air compressor saves you time and effort while ensuring that it continues to serve you for an extended period.In conclusion, owning a car comes with its responsibilities, and one of them is ensuring that your vehicle is well-maintained at all times. One way to achieve this is by investing in an air compressor that is both durable and reliable. One such air compressor is readily available in the market from a renowned brand. It is a top-rated product and has been designed to be the perfect addition to your garage. With features such as durability, easy operation, and minimal maintenance, investing in this air compressor is an investment that will pay off in the long run.