Ultimate Guide to Oil-Injected Screw Air Compressors

By:Admin

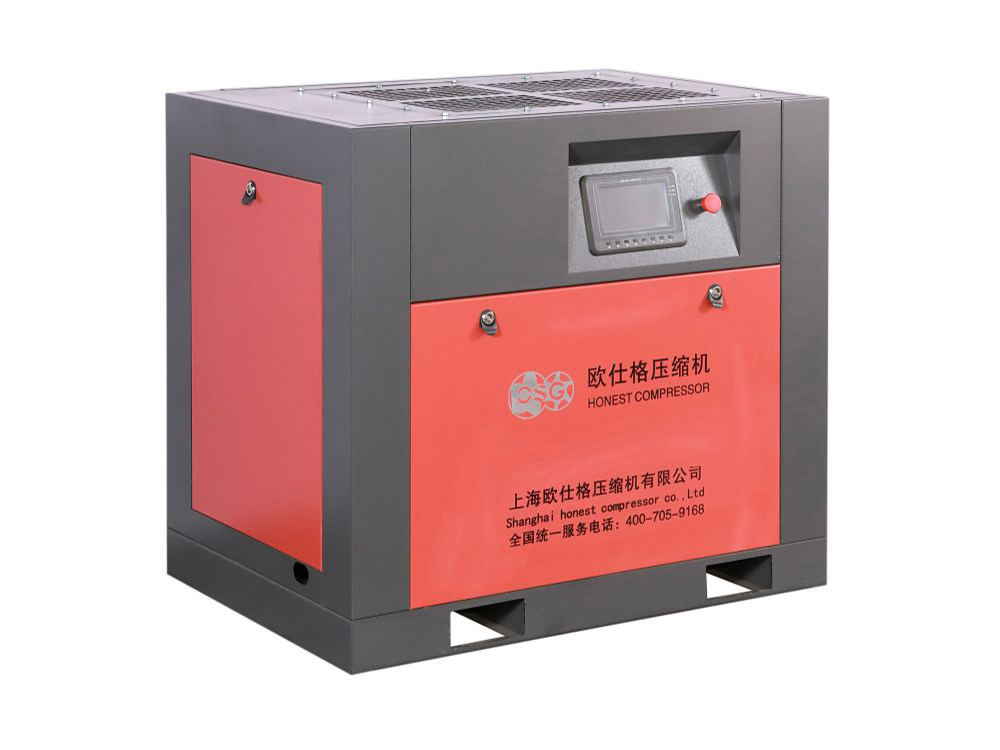

Air compressors have become an essential aspect of several industrial processes. From painting to pneumatic tools to manufacturing, air compressors are used extensively in various industries. It is crucial to choose the right air compressor for achieving the desired output. The oil-injected screw air compressor has revolutionized the air compressor industry. The compressor's design and functionality make it one of the most popular choices among the industrial players. In this news article, we will discuss this compressor's features and how it has transformed various sectors.

Features of Oil Injected Screw Air Compressor

The oil-injected screw air compressor (model number need to remove) is a cutting-edge technology that features the latest design and features. The compressor has two screws in the inlet, which means the machine reduces energy loss and leakages. The configuration of the screws is such that they don't touch each other, ensuring the lifespan of the machine is extended. The compressor's thermal stability is exceptional, which enables the machine to operate continuously even under high pressure.

The oil-free air compressor works by oil injected into the compressor, which lubricates the moving parts such as the moving screw and cylinder. It also seals gaps and cracks, reducing leakages. The oil is later filtered out to ensure the air that comes out of the compressor is free from any contaminants.

The most significant advantage of the oil-injected screw air compressor is its efficiency. The compressor is designed to handle high-pressure environments without consuming significant amounts of energy. The machine's specific power consumption is relatively low when compared to other compressors in the industry. This cuts down operational costs and improves the machine's environmental footprint. Additionally, the compressor features an advanced control system that is user-friendly and offers a wide range of customization options.

Application in various industries

The oil-injected screw air compressor has become a game-changer in the air compressor industry and has found applications in various sectors. The usage of this compressor can be found in industries such as automotive, textiles, food and beverage, oil and gas, plastics, and many more. The compressor is preferred in industries where efficiency, reliability, and less maintenance are critical.

The automotive industry uses the compressor for several tasks. The compressor can be used for painting, providing power to pneumatic tools, and operating assembly lines. The compressor's exceptional pressure and specific power consumption make it the most appropriate choice for various applications in the automotive industry.

Textile manufacturing requires compressed air for several processes such as spinning, weaving, dyeing, and finishing. The oil-injected screw air compressor is extensively used in the textile industry as it helps ensure production efficiency. The compressor's high pressure, energy efficiency, and low maintenance requirements make it an ideal choice for textile industries.

The food and beverage industry uses compressed air for several processes such as vacuum packaging, filling, quality control, and cleaning. The oil-injected screw air compressor with oil filtering system ensures that the compressed air used in these processes is free from contaminants, thereby ensuring food safety.

The oil and gas industry requires compressed air for several applications such as pipeline cleaning, pressure testing, and tool powering. The compressor's rugged design and reliability make it an ideal choice for various applications in the oil and gas industry.

Conclusion:

The oil-injected screw air compressor is undoubtedly a game-changer in the air compressor industry. Its high efficiency, low maintenance, and reliability make it an ideal choice for several industries. With its energy efficiency and environmental friendliness, it is not just good for industries but also for society as a whole. The compressor (model need to be removed) has dramatically changed the outlook of the air compressor industry and will continue to do so in the future.

Company News & Blog

Compressor Manufacturers, Dealers and repairers in India: Find Suppliers for Refrigeration and Air Compressors

Compressors play a critical role in various sectors of the Indian economy, ranging from agriculture to manufacturing, construction, and transportation. A compressor is a device that uses mechanical energy to compress gases. It is widely used in many industries because it helps to store and transport gases more efficiently and safely.India has a thriving market for compressors, with many manufacturers, dealers, and suppliers competing to meet the diverse needs of their customers. Some of the leading compressor brands in India include Atlas Copco, Ingersoll-Rand, Kaeser, ELGi, and Sullair. However, there are also many other local and regional players in the market who offer quality products at competitive prices.The Indian compressor market is projected to grow at a CAGR of 6.57% between 2021 and 2026, fueled by rising demand from various industries. The growth of the agriculture and construction sectors, along with the expansion of the oil and gas industry, is expected to drive the demand for compressors in the coming years. Additionally, the increasing adoption of automation and robotics in manufacturing processes is likely to boost the demand for compressed air systems.Various types of compressors are available in the Indian market, including reciprocating, rotary screw, centrifugal, and portable compressors. Reciprocating compressors are widely used in small-scale industries, while rotary screw compressors are preferred in larger industries due to their high efficiency and low maintenance costs. Centrifugal compressors are commonly used in the oil and gas industry and other high-pressure applications, while portable compressors are popular in construction and mining sites.Leading compressor manufacturers in India offer a range of services, including compressor rental, maintenance, repair, and spare parts supply. Compressor rental services allow customers to use high-quality compressors without making a significant upfront investment. Maintenance and repair services help to ensure that compressors are functioning optimally, reducing downtime and maintenance costs. Spare parts supply ensures that customers can find the parts they need to repair their compressors quickly and efficiently.One of the leading compressor manufacturers in India is [Company Name], which has been providing high-quality compressors and compressor services to customers in India and abroad for over [Number of years] years. The company offers a wide range of compressor types, including reciprocating, rotary screw, and centrifugal compressors, as well as accessories and spare parts. Additionally, they provide compressor rental and maintenance services to ensure that customers' compressors are always in premium condition.[Company Name] is committed to providing excellent customer service and ensuring that their products and services exceed customer expectations. Their team of highly skilled technicians and engineers work closely with customers to develop customized solutions that meet their specific needs. They also offer comprehensive training programs to help customers operate their compressors efficiently and safely.In conclusion, the Indian compressor market is poised for significant growth in the coming years, driven by rising demand from various industries. The availability of diverse compressor types and services, coupled with the expertise of leading manufacturers and suppliers like [Company Name], will continue to play a vital role in meeting the needs of Indian businesses. With the right investments and strategies, the Indian compressor market has the potential to become a global leader in the coming years.

Get Your Hands on Air Compressors for Sale Online or In-Store – Shop Now at Australia's Leading Tool Shop with Afterpay Option Available!

When it comes to finding the best tools for your DIY project or business, it's essential to get the right equipment for the job. One such tool that is critical for anyone who wants to work with compressed air is an air compressor. Air compressors offer many benefits, including convenience, high performance, and easy handling. With so many options available in the market, it can be a daunting process trying to find the best air compressor that suits your needs. But fortunately, there's a tool supplier that has been trusted by many Australians for years.Tools Warehouse is a leading independent tool shop that carries a broad range of quality air compressors for sale online or in-store. The company understands the importance of having reliable tools and equipment, which is why it provides only the best brands in the market. Whether you're searching for a portable or stationary air compressor, you can trust Tools Warehouse to have what you need.One of the popular types of air compressors available is the direct drive air compressor. A direct drive air compressor refers to a compressor that's connected directly to the motor. This type of compressor is compact, lightweight, and portable, making it an ideal tool for DIY projects and small businesses that require mobility.At Tools Warehouse, you can find a range of direct drive air compressors for sale from various trusted brands. These compressors are available in different sizes, horsepower, and voltage, making it easy for you to choose the right one for your needs. Some of the most popular brands that Tools Warehouse carries include Milwaukee, Kincrome, and JetAir. These brands are known for their durability, power, and performance, making them an excellent choice for professionals and enthusiasts alike.One of the best things about buying from Tools Warehouse is that they offer flexible payment options, including Afterpay. With Afterpay, you can purchase your air compressor today and pay for it later in four easy installments, making it easier than ever to get the tools you need.Besides offering a wide range of air compressors for sale, Tools Warehouse is also committed to providing excellent customer service. As a business dedicated to serving its customers, Tools Warehouse has a team of friendly and knowledgeable staff who can help you with any queries. The company also offers free shipping for orders over $100, making it even more convenient to shop online.In conclusion, if you're in the market for a direct drive air compressor, look no further than Tools Warehouse. With a diverse range of quality air compressors for sale, including Afterpay, you can easily find the best compressor for your needs. So, visit Tools Warehouse today and take advantage of their excellent deals and customer service.

Industry Spotlight: The Advantages of Portable Rotary Screw Air Compressors

As the demand for portable rotary screw air compressors continues to rise, companies are constantly innovating to meet customer needs. One such company, which is well-known in the industry for producing high-quality air compressors, has recently launched a new portable rotary screw air compressor that promises to be a game changer for professionals.This new compressor, which features advanced technology and innovative design, has been designed to provide reliable and efficient performance in even the most demanding work environments. With its compact and lightweight design, it can easily be transported from one job site to another, making it ideal for contractors and other professionals who need to work in different locations.The compressor is powered by a high-performance, energy-efficient motor that delivers the perfect amount of air pressure for a range of applications. Its advanced filtration system ensures that the air is clean and free of contaminants, which is essential for applications where clean air is critical. Additionally, the compressor features a rugged construction that is built to withstand the toughest work conditions, ensuring that it can be relied upon for years to come.One of the standout features of this new portable rotary screw air compressor is its user-friendly control panel. Designed with ease of use in mind, the control panel is intuitive and easy to navigate, allowing even novice users to operate the compressor with ease. From here, users can adjust the air pressure, monitor the oil level, and track the compressor's runtime, among other things.In addition to its advanced features and innovative design, this new compressor is backed by the company's renowned customer service and support. With a strong commitment to customer satisfaction, the company offers comprehensive support, including maintenance, repair, and technical assistance, ensuring that users get the most out of their compressor.According to the company spokesperson, "We are excited to launch this new portable rotary screw air compressor, which reflects our commitment to innovation and quality. We understand that our customers require robust and reliable equipment that can perform even in the most demanding work environments, and we are proud to deliver a product that meets those needs."Experts in the industry have also expressed their enthusiasm about this new compressor, praising its innovative design, advanced features, and use of high-quality materials. They predict that it will quickly become a favorite among professionals in a range of industries, including construction, manufacturing, and more.Overall, this new portable rotary screw air compressor is an impressive addition to the market, offering users an efficient and reliable option for their compressed air needs. With its advanced technology, user-friendly design, and superior performance, it is sure to become a go-to choice for professionals seeking a top-quality compressor that delivers results every time.

Discover the Benefits of Industrial Screw Type Air Compressors for Effective Operations

Industrial Screw Type Air Compressor Solutions for Efficiency and Cost-EffectivenessIn today's fast-paced and competitive world, businesses and industries alike require machinery and equipment that are efficient, reliable and cost-effective. Among these indispensable machines is the industrial air compressor, which provides compressed air for a wide range of applications, including manufacturing, woodworking, automotive repairs, and more.Industrial Screw Type Air Compressor (name not disclosed) is a global leader in compressed air solutions. With more than 100 years of experience in the industry, the company is committed to providing innovative technologies that deliver high efficiency, low maintenance and energy savings to their clients worldwide.The company's signature product, the industrial screw type air compressor, is a versatile and robust machine that is designed to meet the needs of diverse industries. With features like variable speed technology, energy-efficient motors, and advanced controls, Industrial Screw Type Air Compressor offers a range of options that cater to various applications and budgets.Whether it's a small workshop or a large manufacturing plant, the company's air compressors are designed to deliver optimal performance, reliability, and durability. The industrial screw type compressor range is available in various horsepower, ranging from 2hp to 500hp, and pressure ratings up to 200psi.One of the unique features of Industrial Screw Type Air Compressor is its R&D capabilities. The company's team of engineers and technicians are constantly researching and developing new technologies to improve the efficiency and performance of their products. This emphasis on research and innovation has led to the development of several patented technologies, such as Neo Standard Oil-free Scroll Compressor, Magna Drive, and Leak Detection System, among others.Additionally, Industrial Screw Type Air Compressor's commitment to sustainability is evident in its Eco-Smart range of air compressors. These energy-efficient machines are designed to reduce energy consumption, lower carbon emissions, and promote a greener environment. The company's Eco-Smart range is also compliant with international standards on safety and quality.Industrial Screw Type Air Compressor's global footprint spans across 85 countries, with a network of distributors and service centres that provide technical support, training, and after-sales services to their clients. The company's dedication to customer service is reflected in its comprehensive warranty policies and extended service plans.In conclusion, the Industrial Screw Type Air Compressor is a reliable and efficient solution for businesses and industries that require compressed air for their daily operations. With its high performance, low maintenance, and energy-saving features, this machine offers a cost-effective solution that not only improves productivity but also contributes to sustainable practices. Furthermore, Industrial Screw Type Air Compressor's commitment to research and innovation, customer service, and sustainability ensures that its products remain at the forefront of industrial air compressor technology.

Screw Air Compressors: Your Solution for Air Compressing Needs

Mobile Screw Compressor – Making Air Compressing More ConvenientWhen it comes to industrial applications, air compressors are indispensable. They serve as the source of power for a lot of machines and equipment. However, like all other machines, air compressors too demand a certain level of care and maintenance. But, imagine if there was an air compressor that was not only reliable, but also mobile enough to be taken from one place to another easily. That's where the Mobile Screw Compressor comes in.With the advent of technology, the manufacturing industry has seen a lot of advancements. As a result, a lot of new and improved types of air compressors are now available in the market. But, the Mobile Screw Compressor stands out with its convenience and portability. Let us take a closer look at what a mobile screw compressor is, its features, and its benefits.What is a Mobile Screw Compressor?A Mobile Screw Compressor is a type of air compressor that is designed to be easily moved from one location to another. These compressors come equipped with wheels, handles, and other features that make it much easier to transport. They are specifically designed to cater to industries that require compressed air at several locations. These compressors are compact, efficient, easy to service, and can be powered by a variety of power sources.The Features of a Mobile Screw CompressorA Mobile Screw Compressor comes packed with a lot of features that make it a reliable and efficient choice for industries that require compressed air. Here are a few notable features:1. Compact Design – Mobile Screw Compressors have a compact design that makes it possible to transport them in areas with space restrictions.2. Extreme Mobility – With wheels and handles, it's a breeze to move the compressor from one location to another.3. Non-Stop Compressed Air – The compressor has a built-in air receiver that enables it to automatically stop and start according to the requirements.4. Noiseless Operation – The Mobile Screw Compressor is designed to operate quietly without causing any disturbance in the workplace.5. High-Quality Material – The compressor is made up of high-quality materials that guarantee durability and longevity.The Benefits of Owning a Mobile Screw CompressorA Mobile Screw Compressor offers a host of benefits to industries that require compressed air. Here are a few notable ones:1. Increased Efficiency - With the Mobile Screw Compressor, compressed air is available wherever it is required, which increases efficiency and productivity.2. Easy to Transport - Because of its compact design and mobility, the compressor can be effortlessly moved to any location.3. Improved Accessibility - A Mobile Screw Compressor can be used in remote locations that don't have access to a power source. This is because it can be powered by a range of sources including generators, trucks, and tow vehicles.4. Reduced Downtime - With the non-stop compressed air feature, there is no need to wait for the air to build up again. Tasks can be completed faster, and the overall downtime is reduced.5. Noiseless Operation - It operates quietly, whatever the work environment, resulting in a better work experience and a more harmonious environment.ConclusionThe Mobile Screw Compressor is a practical piece of equipment that is designed to make air compressing more convenient. Due to its compact design, easy mobility, and range of features, it has become the right choice for many industries which require compressed air at multiple locations. It's a durable and reliable machine that can be powered in various ways and provides non-stop compressed air to guarantee productivity and efficiency. If you're looking for a reliable and efficient air compressor, consider investing in a Mobile Screw Compressor.

Discover the Advantages of Water-Injected Screw Compressors for Enhanced Performance

Water Injected Screw Compressor: A Revolutionary Solution to Energy and EfficiencyIn recent years, the need for energy-efficient equipment and solutions has become more prominent than ever before. With the rising costs of electricity and the growing environmental concerns, companies have been compelled to seek out innovative and sustainable ways to optimize their operations. This is where the Water Injected Screw Compressor comes in - a game-changing technology that promises unparalleled energy savings and performance.Firstly, what is a Water Injected Screw Compressor? It is an advanced air compression system that employs water as a cooling agent instead of traditional oil. The process involves injecting water into the compression cycle, which reduces the temperature and eliminates the need for oil lubrication. This not only results in decreased environmental impact but also leads to increased efficiency, reliability, and cost-effectiveness.One of the forerunners of this cutting-edge technology is a leading industrial air compressor manufacturer with over 100 years of experience in the industry. Their innovative Water Injected Screw Compressor has been hailed as a significant breakthrough in the field of air compression, offering exceptional performance and energy savings.The Water Injected Screw Compressor offers several benefits that make it an attractive option for various industries. Some of these advantages include:Energy Efficiency: The Water Injected Screw Compressor has a low energy consumption rate, thanks to its water cooling system. It can reduce electricity costs by up to 37%, which translates to significant savings for businesses.Increased Reliability: The elimination of oil lubrication in the compression cycle reduces the risk of system breakdowns, enhancing reliability and providing a longer lifespan for the equipment.Low Environmental Impact: The environmentally-friendly design of the Water Injected Screw Compressor eliminates oil usage, reducing the carbon footprint and promoting sustainability.Low Maintenance Cost: The simplified design of the Water Injected Screw Compressor requires less maintenance than traditional compressors, leading to reduced maintenance costs and increased uptime for businesses.Flexibility: The Water Injected Screw Compressor is versatile and can be customized to meet the specific needs of various industries, making it a practical solution for a wide range of applications.The Water Injected Screw Compressor has been widely adopted in many industries, including automotive, food and beverage, pharmaceuticals, and more. Its innovative technology has helped companies improve their operational efficiency while simultaneously reducing their environmental impact.In conclusion, the Water Injected Screw Compressor is an exceptional technology that has revolutionized air compression and set a new industry standard for efficiency and sustainability. With its incredible energy savings, increased reliability, and low environmental impact, it is a must-have solution for businesses that seek to optimize their operations and reduce their carbon footprint. Companies can rely on trusted manufacturers like ours to provide them with high-quality and customizable Water Injected Screw Compressors that meet their unique needs and drive their success.

High-Performance Screw Air Compressor - Product by Leading Manufacturer

When it comes to powering tools and machinery, a reliable air compressor is an essential piece of equipment. For those needing a powerful and portable option, a rotary screw air compressor is an excellent choice. In this article, we’ll explore what a rotary screw air compressor is, how it works, and the benefits it can bring, as well as taking a closer look at portable screw air compressors.What is a rotary screw air compressor?A rotary screw air compressor is a type of air compressor that works by using two rotors, or screws, to compress air. These rotors spin in opposite directions within a specially-designed housing, compressing and releasing air as they move. This process creates a continuous flow of compressed air that can be used for powering tools, machinery, or other equipment.One of the main benefits of a screw compressor is its high efficiency. Unlike some other types of compressors, the compressed air produced by a screw compressor is free from pulsations and surges, meaning it is smooth and even. This can help to reduce wear and tear on machinery and improve performance.How does a rotary screw air compressor work?As mentioned above, a rotary screw air compressor uses two rotors to compress air. These rotors are typically helical in shape, meaning they have a spiral groove that runs along their length. As the rotors turn, the air that is trapped between them is forced into these grooves and gradually compressed. This process continues until the compressed air is released at the outlet port.One of the advantages of a screw compressor is that it can operate continuously, making it ideal for applications where a consistent supply of compressed air is needed. Additionally, because there is no need for a cooling period between compression cycles, a screw compressor can be more energy-efficient than some other types of air compressors.What are the benefits of a rotary screw air compressor?There are several advantages to using a rotary screw air compressor. Firstly, as mentioned earlier, they are highly efficient, providing a continuous supply of compressed air that is free from pulsations and surges. This can help to reduce wear and tear on machinery and improve performance.Another benefit of a screw compressor is that it can produce a large volume of compressed air in a small amount of time. This can make them ideal for use in manufacturing or construction environments where a high volume of compressed air is needed.Finally, rotary screw air compressors are also highly versatile. Depending on the application, they can be used for a wide range of tasks, from powering tools to inflating tires.Portable screw air compressorsFor those needing a powerful and portable option, a portable screw air compressor is an excellent choice. These compact compressors are designed to be easy to transport and use on-site, making them ideal for construction, automotive, and other industries.One of the key advantages of a portable screw air compressor is that it provides a high level of mobility. Many models are designed to be small and lightweight, allowing them to be easily transported from one location to another. Additionally, many models come with wheels or handles, making them even more portable.Another benefit of a portable screw air compressor is that it is typically very straightforward to set up and use. Many models come with easy-to-follow instructions and require minimal setup, meaning workers can quickly begin using them on-site.In conclusion, rotary screw air compressors are invaluable pieces of equipment for those needing a reliable and efficient source of compressed air. Whether you are a professional mechanic, contractor, or DIY enthusiast, a screw compressor can provide a continuous supply of compressed air to power your tools and equipment. And if you need a portable option, a portable screw air compressor is an excellent choice. With its ease of use and mobility, it’s a must-have for anyone needing a powerful and portable air compressor.

Discover More About 1625423008: 15KW Cooler Unit and Its Benefits

Global manufacturing companies are investing heavily in innovative technologies to gain a competitive edge and streamline their operations. To support these efforts, Atlas Copco (brand name removed) has introduced the COOLER 15KW, an advanced cooling system designed to help companies achieve peak performance in their operations.The COOLER 15KW is the latest addition to the Atlas Copco range of industrial cooling solutions, designed for a wide range of applications and industries. This cutting-edge system is capable of delivering up to 15,000 watts of cooling capacity, ensuring machinery and equipment remain at optimal temperatures to avoid overheating and breakdowns. This is especially important in demanding industrial applications, where machinery can be subjected to extreme conditions that can cause wear and tear, leading to operational inefficiencies and increased downtime.The COOLER 15KW features a compact and efficient design, incorporating a range of advanced features to deliver superior performance. These features include robust temperature and pressure controls, which enable users to monitor and regulate cooling performance in real-time. The unit also includes a range of safety mechanisms to ensure reliable and safe operation, including overheat protection and alarms.One of the key benefits of the COOLER 15KW is its energy efficiency, achieved through the use of advanced technologies such as variable speed drives and electronic expansion valves. These features enable the system to regulate cooling performance more precisely, reducing energy consumption and improving overall efficiency. This makes the COOLER 15KW an ideal choice for companies looking to reduce their carbon footprint and operating costs.The COOLER 15KW is designed to meet the highest quality standards, ensuring maximum reliability and durability. The unit is built to withstand harsh industrial environments, with high-quality components that are resistant to corrosion and wear. Additionally, the unit comes with a two-year warranty, giving users peace of mind and ensuring optimal performance for years to come.Atlas Copco is a leading provider of industrial cooling solutions, with a reputation for innovation and quality. The company has a global network of sales and service offices, providing customers with local support and expertise. The COOLER 15KW is the latest addition to the Atlas Copco range, representing the company's commitment to delivering cutting-edge solutions that meet the evolving needs of its customers.In summary, the COOLER 15KW is a gamechanger for companies operating in demanding industrial applications. This advanced cooling system delivers superior performance, reliability, and energy efficiency, ensuring machinery and equipment remain at optimal temperatures for maximum productivity. By investing in the COOLER 15KW, companies can gain a competitive advantage in their industry while reducing their carbon footprint and operating costs. To learn more about the COOLER 15KW, contact your local Atlas Copco sales office today.

Guide to Choosing Between Oil-free and Oil-injected Air Compressors for Your Business or Organization

Choosing the right air compressor for your business or organization can be a daunting task, especially if you aren't familiar with the different types of air compressors available. There are two main types of air compressors on the market today – oil-free compressors and oil-injected compressors. In this blog post, we'll take a closer look at both types of compressors and help you determine which one is best suited for your needs.Oil-Free Air Compressors:Oil-free air compressors are designed to operate without the need for oil lubrication in the compression chamber. These compressors use a non-stick coating on the compression chamber walls to reduce friction and prevent build-up of unwanted materials within the air compression system. This type of compressor is ideal for facilities that require a zero-risk level of contamination, such as pharmaceutical plants, electronics manufacturing facilities, and food processing plants.One of the distinct advantages of oil-free compressors is that they produce clean air flow with no oil contaminants. This makes oil-free compressors ideal for environments where clean air supply is essential. On the other hand, oil-free compressors generally have a shorter lifespan than their oil-injected counterparts as they operate under higher temperatures and pressures.Oil-Injected Air Compressors:Oil-injected air compressors are the most common type of air compressor found in manufacturing processes today. These compressors require oil lubrication in the compression chamber to cool moving parts, reduce friction and absorb heat, and improve the operational efficiency. Oil-injected compressors are designed to withstand heavy use and are ideal for applications that require continuous operation, such as factories, mechanical workshops, and construction sites.One of the distinct advantages of oil-injected compressors is that they have a longer lifespan than oil-free compressors as they operate under lower temperatures and pressures. Additionally, oil-injected compressors are known for their superior performance, high-output capabilities, and versatile work portfolio. However, they require regular oil changes, and there is always a risk of oil contamination, particularly in applications where clean air supply is essential.Oil Injected Screw Air Compressor:If you're in the market for an oil-injected air compressor, you may want to consider purchasing an oil-injected screw air compressor. Compared to oil-free compressors, oil-injected screw air compressors have a longer lifespan, higher efficiency, and higher output capacity. They can handle a variety of tasks, from powering air tools and pneumatic machinery to inflating tires and powering large air conditioning systems.Screw air compressors are designed with two interlocking screws that compress air to provide high levels of output at lower power input levels. This type of compressor operates quietly, with minimal vibration and produces clean air flow with low oil consumption, making it ideal for a wide range of applications.In conclusion, choosing the right air compressor for your business or organization can be difficult. However, by understanding the advantages and disadvantages of both oil-free and oil-injected compressors, you can select the compressor best suited for your needs. If you're looking for an efficient, versatile, and reliable air compressor, an oil-injected screw air compressor may be the perfect solution for you. Whatever your choice may be, it pays to do your research and invest in a high-quality compressor that will serve your needs for years to come.