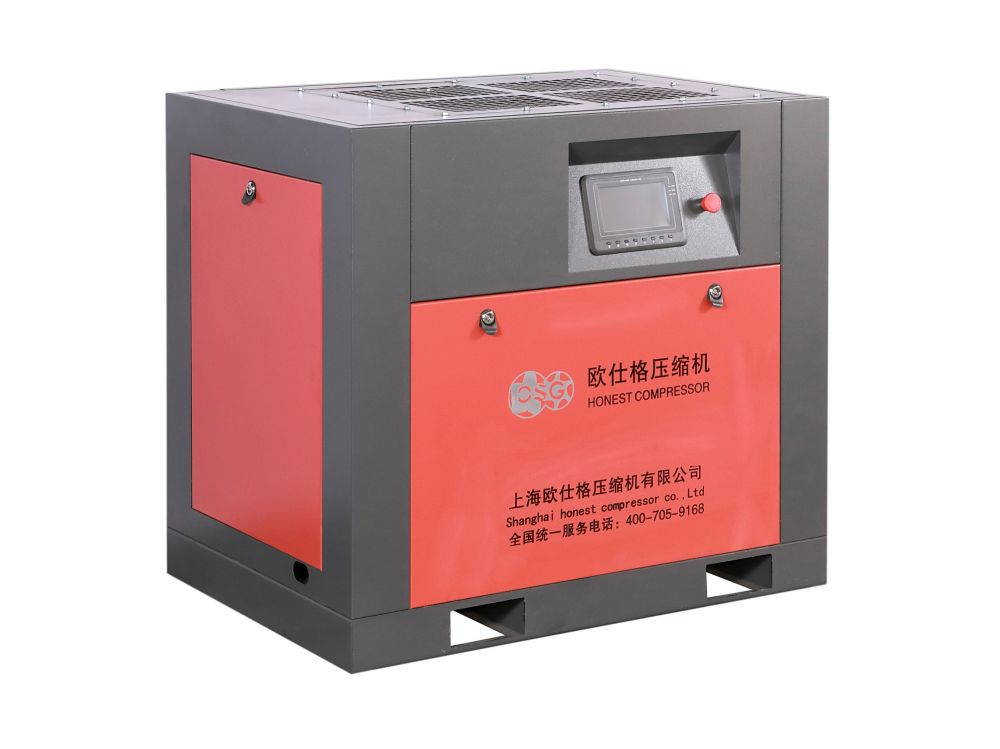

New High-Performance Screw Compressor Machine Released for Industrial Use

By:Admin

Introduction:

In today's fast-paced industrial landscape, efficiency and reliability are crucial elements for success. One company, renowned for its cutting-edge technology, has been revolutionizing the industry with its state-of-the-art Screw Compressor Machine. Combining innovation, durability, and unparalleled performance, this compressor sets new benchmarks in the field. Let us delve deeper into the functionalities and benefits offered by this exceptional product.

Section 1: Screw Compressor Machine Overview

The Screw Compressor Machine, developed by a leading industrial solutions provider, is a game-changer in multiple industries. Widely used in manufacturing, construction, oil and gas, automotive, and other sectors, this advanced machinery possesses several unique features.

The compressor employs a twin-screw design that efficiently compresses air or gas. The tightly meshed rotating screws create a continuous flow of compressed air, resulting in enhanced productivity and reduced energy consumption. Additionally, the patented cooling system ensures optimal heat dissipation, guaranteeing prolonged operation without any performance degradation.

Section 2: Key Features and Functionality

1. High Efficiency: The Screw Compressor Machine boasts exceptional efficiency rates due to advanced engineering techniques. It combines performance-enhancing elements like precision-honed rotors, specialized lubrication system, and efficient motor technology, resulting in maximum output with minimal energy input.

2. Intelligent Control System: Equipped with a state-of-the-art control panel, the machine allows precise monitoring of critical factors such as temperature, pressure, and power consumption. This intelligent system ensures optimal functionality, enabling operators to make real-time adjustments for enhanced performance and reduced downtime.

3. Versatile Applications: With its adaptability, the Screw Compressor Machine can be tailored to suit various application requirements. From compressed air supply for pneumatic tools to high-pressure applications in gas pipelines, this compressor delivers exceptional performance across multiple scenarios.

Section 3: Advantages and Benefits

1. Energy Efficiency: The advanced design of the Screw Compressor Machine ensures maximum air compression with minimal energy consumption. By utilizing energy-saving features and continuous monitoring, it significantly lowers overall operational costs.

2. Durability and Reliability: Built with robust materials and engineering techniques, the compressor offers an extended operational lifespan. With regular maintenance and minimal downtime, it guarantees uninterrupted productivity, minimizing losses due to equipment failure.

3. User-Friendly Design: The Screw Compressor Machine incorporates user-friendly interfaces, making it accessible to operators of varying expertise levels. The ergonomic design promotes ease of use, maintenance, and troubleshooting, thereby reducing human errors and increasing operational efficiency.

4. Reduced Environmental Impact: In line with global sustainability initiatives, the compressor adopts eco-friendly practices. Its energy-efficient operation reduces carbon emissions while the use of environmentally friendly refrigerants protects the ozone layer, ensuring a greener future.

Section 4: Company Background and Dedication to Innovation

The company behind this groundbreaking Screw Compressor Machine has a rich history of providing advanced industrial solutions. With a focus on research and development, they consistently strive to revolutionize industry standards. Their commitment to innovation, customer satisfaction, and environmental responsibility has earned them a strong reputation and a global clientele.

Conclusion:

The Screw Compressor Machine signifies a remarkable advancement in industrial machinery. Its unmatched efficiency, durability, and adaptability make it an essential asset for industries globally. With its ability to optimize performance, reduce environmental impact, and enhance profitability, this compressor demonstrates the epitome of cutting-edge technology. As the demands of modern industries continue to evolve, the Screw Compressor Machine stands ready to meet and exceed expectations, fostering a more productive and sustainable future.

Company News & Blog

Vertical Air Compressor for Oil-Free Operations: Latest News

[Introduction]In the ever-evolving world of industrial equipment, innovation plays a crucial role in meeting the needs of various industries. One such innovation is the development of oil-free vertical air compressors, which have revolutionized the compressor industry by providing cleaner and more efficient air compression solutions. (Brand name removed), a renowned name in the industrial equipment market, has taken a significant step forward with their latest oil-free vertical air compressor.[Company Introduction]Founded in (year), (Company name) has established itself as a global leader in providing cutting-edge industrial equipment and solutions. With a commitment to innovation, quality, and customer satisfaction, the company has earned a reputation for delivering products that exceed industry standards. (Brand name) has an extensive range of products, including air compressors, generators, pumps, and more, catering to the diverse needs of industries such as manufacturing, construction, healthcare, and energy.The company's state-of-the-art facilities and advanced manufacturing technologies enable them to develop world-class products. Their team of experienced engineers and technicians work tirelessly to design, test, and manufacture equipment that meets the ever-changing demands of modern industries. With a focus on sustainability, (Company name) ensures that their products have minimal environmental impact while maximizing efficiency.[Oil-Free Vertical Air Compressor]Recognizing the growing need for cleaner air compression solutions, (Company name) has launched its latest oil-free vertical air compressor. This compressor is designed to provide businesses with a reliable and efficient solution that eliminates concerns related to oil contamination.Oil contamination has long been a challenge for industries that require compressed air, as even a tiny amount of oil can negatively impact the performance and longevity of the equipment using it. Traditional compressors, although widely used, often introduce oil into the compressed air, leading to costly maintenance and potential risks to the end-products or processes.The new oil-free vertical air compressor from (Company name) overcomes these challenges by ensuring 100% oil-free compressed air. This eliminates the risk of oil contamination, allowing businesses to operate with peace of mind knowing that their applications and products are not compromised.The key features of the oil-free vertical air compressor include:1. Advanced Technology: The compressor is equipped with state-of-the-art technology that ensures efficient and reliable operation. The cutting-edge design and precision-engineered components minimize energy consumption, resulting in significant cost savings for businesses.2. Vertical Configuration: The vertical configuration of the compressor optimizes floor space utilization, making it ideal for industries with limited space. The compact design and vertical arrangement also simplify installation and maintenance processes.3. Enhanced Performance: The oil-free vertical air compressor delivers consistent performance, ensuring a steady supply of clean compressed air. This is essential for industries requiring high-quality air, such as pharmaceuticals, electronics, food processing, and more.4. Low Maintenance: The elimination of oil in the compression process reduces wear and tear on components, resulting in reduced maintenance requirements and extended equipment lifespan. This translates into cost savings for businesses.5. Environmentally Friendly: The absence of oil in the compressed air not only benefits the end-products or processes but also contributes to a cleaner and healthier environment. Reduced oil consumption leads to lower carbon emissions, supporting sustainability initiatives.(Company name)'s commitment to customer satisfaction is reflected in the warranty and after-sales service provided with their oil-free vertical air compressor. Their dedicated support team ensures prompt assistance in case of any issues or inquiries, ensuring minimal downtime for businesses.[Conclusion]The introduction of (brand name removed)'s oil-free vertical air compressor marks a significant advancement in the field of air compression technology. Solving the long-standing challenge of oil contamination, this compressor offers businesses a reliable, efficient, and environmentally friendly solution. With their unwavering commitment to innovation and customer satisfaction, (Company name) continues to push the boundaries of industrial equipment, empowering businesses across various industries to achieve optimal performance and productivity.

Compressor Manufacturers, Dealers and repairers in India: Find Suppliers for Refrigeration and Air Compressors

Compressors play a critical role in various sectors of the Indian economy, ranging from agriculture to manufacturing, construction, and transportation. A compressor is a device that uses mechanical energy to compress gases. It is widely used in many industries because it helps to store and transport gases more efficiently and safely.India has a thriving market for compressors, with many manufacturers, dealers, and suppliers competing to meet the diverse needs of their customers. Some of the leading compressor brands in India include Atlas Copco, Ingersoll-Rand, Kaeser, ELGi, and Sullair. However, there are also many other local and regional players in the market who offer quality products at competitive prices.The Indian compressor market is projected to grow at a CAGR of 6.57% between 2021 and 2026, fueled by rising demand from various industries. The growth of the agriculture and construction sectors, along with the expansion of the oil and gas industry, is expected to drive the demand for compressors in the coming years. Additionally, the increasing adoption of automation and robotics in manufacturing processes is likely to boost the demand for compressed air systems.Various types of compressors are available in the Indian market, including reciprocating, rotary screw, centrifugal, and portable compressors. Reciprocating compressors are widely used in small-scale industries, while rotary screw compressors are preferred in larger industries due to their high efficiency and low maintenance costs. Centrifugal compressors are commonly used in the oil and gas industry and other high-pressure applications, while portable compressors are popular in construction and mining sites.Leading compressor manufacturers in India offer a range of services, including compressor rental, maintenance, repair, and spare parts supply. Compressor rental services allow customers to use high-quality compressors without making a significant upfront investment. Maintenance and repair services help to ensure that compressors are functioning optimally, reducing downtime and maintenance costs. Spare parts supply ensures that customers can find the parts they need to repair their compressors quickly and efficiently.One of the leading compressor manufacturers in India is [Company Name], which has been providing high-quality compressors and compressor services to customers in India and abroad for over [Number of years] years. The company offers a wide range of compressor types, including reciprocating, rotary screw, and centrifugal compressors, as well as accessories and spare parts. Additionally, they provide compressor rental and maintenance services to ensure that customers' compressors are always in premium condition.[Company Name] is committed to providing excellent customer service and ensuring that their products and services exceed customer expectations. Their team of highly skilled technicians and engineers work closely with customers to develop customized solutions that meet their specific needs. They also offer comprehensive training programs to help customers operate their compressors efficiently and safely.In conclusion, the Indian compressor market is poised for significant growth in the coming years, driven by rising demand from various industries. The availability of diverse compressor types and services, coupled with the expertise of leading manufacturers and suppliers like [Company Name], will continue to play a vital role in meeting the needs of Indian businesses. With the right investments and strategies, the Indian compressor market has the potential to become a global leader in the coming years.

Best Air Compressors for Garage Use - Maintenance/Repairs - Car Talk Community

In today's fast-paced world, our cars are our lifelines. They take us from point A to point B with ease and speed, making our lives more convenient than ever before. However, owning a car also brings some responsibilities. Keeping your car well maintained is essential to ensure its long-term functionality. One of the crucial requirements for maintaining your car is an air compressor. From inflating tires to powering air tools, air compressors play an essential role in keeping your car in optimal condition.That being said, finding the right air compressor can be a daunting task. There are so many brands and types of air compressors available in the market, each with its unique features and specifications. However, one of the most critical factors to consider while selecting an air compressor is its durability. After all, you don't want to invest in a device you will have to replace every other year.One of the top-rated air compressors for car maintenance and repairs is a product from a well-known brand in the industry. However, to avoid any bias, this article will not mention the brand name. This air compressor is known for its sturdy build and longevity. It is designed to withstand extended usage and harsh environments, making it ideal for use in a garage.Another advantage of this air compressor is that it can be easily connected to a standard electrical outlet. This eliminates the need for any special electrical wiring, making it an easy and hassle-free addition to your garage. Additionally, it is designed to provide optimal performance for its users while ensuring that your electricity bills remain manageable.Another feature that makes this air compressor an excellent choice for car owners is that it is multi-functional. This means that you can use it for various purposes such as inflating tires, powering pneumatic tools, and other tasks that require compressed air. This makes it an added convenience for car owners, as you no longer have to invest in separate devices for individual tasks.More importantly, this air compressor requires minimal maintenance. It is designed to be a hassle-free addition to your garage, and you don't have to worry about maintaining it regularly. In doing so, this air compressor saves you time and effort while ensuring that it continues to serve you for an extended period.In conclusion, owning a car comes with its responsibilities, and one of them is ensuring that your vehicle is well-maintained at all times. One way to achieve this is by investing in an air compressor that is both durable and reliable. One such air compressor is readily available in the market from a renowned brand. It is a top-rated product and has been designed to be the perfect addition to your garage. With features such as durability, easy operation, and minimal maintenance, investing in this air compressor is an investment that will pay off in the long run.

Reliable and Efficient Oil-Injected Screw Compressors for Railway Air Supply - Designed to Handle Harsh Environments

for Railway, GAR Oil-injected Screw Compressor, Railway Air Supply.GAR Oil-injected Screw Compressor for Reliable and Efficient Railway Air SupplyRailway transportation is a significant mode of transportation in many countries worldwide. Railways require a reliable and efficient air supply system for their operations. To ensure that the locomotives run efficiently and smoothly, it is essential to invest in the right equipment. GAR oil-injected screw compressors are ideal compressors for railway applications. They are specially designed to operate in harsh environments and provide a dependable source of compressed air.The main advantage of GAR oil-injected screw compressors lies in their superior performance. These compressors deliver efficient and reliable compressed air, enabling smooth and uninterrupted operation of railway systems. The GAR compressors are built to endure the rugged environment of the railway industry, providing long-lasting benefits for a variety of applications.One of the primary benefits of the GAR oil-injected screw compressor is its reliability. The compressor has a high uptime, ensuring that compressed air is available when it is needed. The screw compressor is designed with robust components that can withstand the rigors of the harsh railway environment. This makes the compressor a cost-effective solution for railway operators.Another advantage of GAR oil-injected screw compressors is their efficiency. The compressor design ensures that compressed air is delivered at a constant pressure, providing rail operators with consistent performance. The compressors have low energy consumption features, making it an efficient solution for railway operations.The GAR oil-injected screw compressor is built to meet the specific requirements of railway applications. It has a unique design that provides a more compact and simplified package, which makes it easy to install and maintain. GAR compressors' design is also tailored to eliminate installation costs and reduce installation time by integrating supplementary equipment, such as air dryers, to improve system efficiency.Additionally, GAR oil-injected screw compressors have a low noise level, which makes them an excellent solution for railway operations. They produce less noise, which helps to maintain a peaceful environment for railway staff and nearby residents. The low noise level also minimizes noise pollution to nearby structures.ConclusionThe GAR oil-injected screw compressor is an ideal solution for railway operators requiring a reliable and efficient air supply system. Its unique design makes it suitable for harsh railway environments, providing long-lasting benefits for a variety of applications. The compressor is easy to install and maintain, ensuring consistent performance and uptime. GAR compressors provide improved efficiency and are cost-effective solutions for railway operators. Investing in GAR oil-injected screw compressors will ensure that your railway systems run efficiently and reliably. Choose GAR compressors to achieve maximum performance with minimal maintenance.Keywords: Screw Compressor Package for Railway, GAR Oil-injected Screw Compressor, Railway Air Supply.

Shop for Air Compressor Pumps Online in India at Affordable Prices - Get Discounts and Offers with COD Available!

Industrial Air Compressor Pump: The Essential Tool for Every IndustryWhen it comes to industrial applications, air compressor pumps play a critical role in powering numerous tools and machinery. These devices generate compressed air to power various pneumatic tools, including impact wrenches, sanders, and spray painters. With the help of air compressor pumps, workers can complete their tasks more efficiently, accurately, and safely.If you are in the industrial sector and require an efficient tool to power your devices, investing in an industrial air compressor pump is a wise choice. With the right air compressor pump, your company can increase productivity, reduce operating costs, and improve the quality of your output. In this blog, we will discuss the features and benefits of air compressor pumps and help you choose the right one for your industrial needs.Features of Industrial Air Compressor Pumps:Power Output: The first feature to consider when choosing an industrial air compressor pump is its power output. The power output is measured by the potential energy produced by the device in cubic feet per minute (CFM). The CFM rating determines the range of pneumatic tools that the compressor can power. For industrial applications, a powerful air compressor pump with a high CFM rating is essential.Tank Size: The second feature to consider when choosing an industrial air compressor pump is the size of the tank. The larger the tank, the more compressed air it can store. A bigger tank is beneficial because it allows the compressor pump to run for more extended periods without shutting off.Noise Level: The third feature to consider is the noise level. An industrial air compressor pump can produce a significant amount of noise, which can be disturbing to nearby workers. To mitigate noise pollution in the workplace, consider choosing a compressor pump with a noise-reducing feature.Portability: The fourth feature to consider is portability. If you need to move the compressor pump from one location to another, choose a device that comes equipped with wheels or a handle for easy transportation.Benefits of Industrial Air Compressor Pumps:Increased Productivity: Air compressor pumps help increase productivity in the workplace by powering pneumatic tools that require less manual labor and generate more output. This means that workers can complete tasks in less time, allowing the business to increase its productivity and profitability.Reduced Operating Costs: By using pneumatic tools powered by air compressor pumps, companies can save on operating costs. These compressors consume less energy compared to other machines, resulting in decreased energy bills.Improved Quality of Output: Air compressor pumps also improve the quality of the output. Powered tools produce more accurate and consistent results, resulting in fewer errors and a more polished final product.Conclusion:In conclusion, industrial air compressor pumps are essential tools for any business that requires consistent and reliable compressed air power for pneumatic tools. When choosing an air compressor pump, consider factors such as power output, tank size, noise level, and portability. With the right air compressor pump, businesses can increase productivity, reduce operating costs, and improve the quality of their output. Choose wisely, and reap the benefits.

Everything You Need to Know About Desiccants: Tips and Insights from Experts

Industrial Desiccant Air Dryer: Why It’s Essential to Your BusinessIn any industrial setting, moisture is one of the major impediments to the proper functioning of equipment and machinery. From rust and corrosion to electrical shorts and malfunctions, the effects of moisture can be devastating to your business. However, with industrial desiccant air dryers, you can eliminate these problems and maintain optimal working conditions all year round.What is a Desiccant Air Dryer?A desiccant air dryer is a device that removes moisture from compressed air systems. By drawing air through a desiccant material, it effectively absorbs and traps moisture before releasing dry air back into your system. In this way, desiccant air dryers are able to provide a reliable solution for maintaining the moisture levels of your compressed air systems at acceptable levels, regardless of the environment.Why is It Important to Maintain Proper Moisture Levels?The presence of moisture in compressed air systems can cause a number of problems, including but not limited to:1. Corrosion and RustMoisture in compressed air can cause corrosion and rust in your equipment and machinery, reducing their lifespan and performance.2. Poor Quality of End ProductsMoisture can cause discoloration, deformities, and other abnormalities in your products. This can lead to higher rejection rates, lower-quality end products, and ultimately, lost profits.3. Equipment Failure and DowntimeMoisture can cause shorts, malfunctions, and other failures in equipment and machinery, leading to costly downtime and lost production.4. Increased Maintenance CostsMoisture can cause wear and tear on your equipment, leading to increased maintenance and repairs. This can result in higher costs, longer downtime, and ultimately, lower profits.5. Health and Safety RisksMoisture can also lead to the growth of mold, fungi, and bacteria, creating health and safety hazards for workers in the industrial setting.How Does an Industrial Desiccant Air Dryer Help?An industrial desiccant air dryer helps to mitigate the risks mentioned above by removing moisture from compressed air systems. By maintaining proper moisture levels, you can improve the reliability, efficiency, and safety of your industrial operations. Here are some of the key benefits of using an industrial desiccant air dryer:1. ConsistencyAn industrial desiccant air dryer can provide consistent moisture removal over time, helping to maintain the optimal working conditions of your compressed air system.2. Increased EfficiencyAn industrial desiccant air dryer can help to reduce the workload on other filtration systems, such as oil separators, by removing moisture and other contaminants from compressed air.3. Reduced Maintenance CostsBy removing moisture from your compressed air system, an industrial desiccant air dryer can help to reduce wear and tear on your equipment and machinery, reducing maintenance and repair costs.4. Improved Quality of End ProductsBy maintaining proper moisture levels, an industrial desiccant air dryer can help to reduce discoloration, deformities, and other abnormalities in your products, ensuring high-quality end products.5. Increased SafetyBy reducing the growth of mold, fungi, and bacteria, an industrial desiccant air dryer can help to create a safer working environment for your employees.Choosing the Right Industrial Desiccant Air DryerWhen choosing an industrial desiccant air dryer, there are a few key factors to consider, including the size and type of your compressed air system, the humidity and temperature levels in your environment, and the amount of moisture in your compressed air system.To ensure that you are getting the right industrial desiccant air dryer for your needs, it’s recommended that you consult with a professional in the industry. They can help you determine the best type and size of industrial desiccant air dryer for your business, as well as provide advice on installation and maintenance.ConclusionIn today’s industrial setting, moisture can be a significant problem for equipment, machinery, and end products. However, with the help of an industrial desiccant air dryer, you can reduce the risks associated with moisture and maintain optimal working conditions all year round. By choosing the right industrial desiccant air dryer and implementing proper installation and maintenance, you can ensure the efficiency, reliability, and safety of your industrial operations for years to come.

Benefits of using an Air Dryer for Compressed Air

In today's world, air dryers have become an integral part of numerous industries. Every industry uses compressed air systems for various applications, such as pneumatics, drying, and conveying. However, compressed air contains moisture that can compromise the quality of the system's air. This moisture can lead to corrosion, leaks, and other operational issues.To combat these challenges, various types of air dryers are available on the market. One such type is the refrigerated air dryer, which cools the compressed air to a dew point where the moisture condenses and can be removed. The advantage of the refrigerated air dryer is its cost-effectiveness and ability to dry air to a dew point that is suitable for many applications. Another type of air dryer is the desiccant air dryer, which uses a drying agent to absorb moisture from the compressed air. This type of air dryer is ideal for applications that require very dry compressed air because it can achieve a dew point as low as -100°F. In addition to these two types of air dryers, there are other solutions available, such as the membrane air dryer that works by separating moisture through a selective permeable membrane and the deliquescent air dryer that uses a salt-based drying agent to absorb moisture. One company that is well-known for its innovative air drying solutions is [Company Name]. The company offers a wide range of air dryers for various applications, including refrigerated air dryers, desiccant air dryers, and membrane air dryers. [Company Name]'s air dryers are designed to provide high-quality compressed air and cater to the diverse requirements of different industries. The company's team of experts work diligently to design, manufacture, and test air dryers to ensure optimal performance, reliability, and durability. The company's refrigerated air dryer series provides an efficient solution for drying compressed air with low to medium flow rates. These air dryers are designed with energy efficiency in mind, enabling them to provide cost-saving benefits to the customer. [Company Name] also offers a desiccant air dryer series that provides clean, dry air ideal for critical applications. These air dryers are designed to handle high flow rates, ensuring that they meet the demanding requirements of industries such as pharmaceuticals, food, and beverage. Further, the company's membrane air dryer series is ideal for customers who require clean and dry compressed air in remote locations where electricity supply is not available. These air dryers are compact, portable, and low-maintenance, making them perfect for different types of field applications. [Company Name] also offers customized solutions that cater to unique customer requirements. The company's team of engineers works closely with customers to design an air drying solution that meets their specific needs. This means that [Company Name] can deliver the perfect air drying solution for any application, whether for simple or complex requirements. The company's commitment to quality is evident in its stringent quality control procedures. All [Company Name]'s air dryers undergo rigorous testing to ensure that each air dryer meets the highest standards. Customer satisfaction is a top priority for the company, and this is ensured with the provision of documentation, installation, and commissioning services, as well as reliable after-sales support. In conclusion, air dryers play a crucial role in many industries by ensuring the delivery of clean, dry compressed air. [Company Name] offers a broad range of air drying solutions that cater to various requirements and applications. The company's commitment to quality, reliability, and customer satisfaction is evident in its products and services. [Company Name] is sure to be a top choice for customers seeking high-quality air drying solutions.

Discover the Advantages of Industrial Oil Free Air Compressors for Efficient Operations

[Industrial Oil-Free Air Compressor] Revolutionizing the Manufacturing Industry[City, Date] - In today's manufacturing sector, efficiency, sustainability, and cleanliness are of paramount importance. With the increasing awareness of environmental concerns and the need for reducing carbon footprints, industries are embracing innovative technologies to enhance their productivity while minimizing their impact on the environment. One such groundbreaking solution that has caught the attention of manufacturers worldwide is the Industrial Oil-Free Air Compressor, designed and developed by a leading industry player.A pioneer in air compressor technology, this company has revolutionized the manufacturing industry with its state-of-the-art oil-free air compressor. Combining advanced engineering techniques with extensive research and development, they have created a compressor that offers numerous benefits to manufacturing facilities, making it an indispensable asset within industrial settings.The Industrial Oil-Free Air Compressor serves as an energy-efficient alternative to traditional oil-lubricated compressors. By eliminating the need for oil, it delivers compressed air that is entirely free from any oil contaminants. This ensures that the air meets the highest standards of purity, making it particularly suitable for industries that demand clean air, such as pharmaceuticals, food and beverages, electronics, and automotive manufacturing.Featuring cutting-edge technology, this air compressor guarantees exceptional performance, reduced maintenance costs, and minimized downtime. The advanced design utilizes a series of precision-engineered components to achieve remarkable efficiency, resulting in significant energy savings for the company. By avoiding the use of oil, manufacturers can eliminate the associated costs of oil procurement, disposal, and maintenance, leading to substantial financial savings.Moreover, the Industrial Oil-Free Air Compressor exceeds regulatory standards set by environmental agencies worldwide. With a focus on sustainability, the company has created a compressor that significantly reduces carbon emissions, contributing to a cleaner and greener environment. By eliminating oil, which is a major source of air pollution, the compressor has achieved an impressive environmental footprint. This makes it an excellent choice for companies aiming to fulfill their corporate social responsibility by adopting eco-friendly practices.The oil-free design also ensures that the compressor operates quietly, without compromising on performance. This feature is particularly valuable for manufacturing units located in urban areas or those situated in close proximity to residential areas. The reduced noise levels promote a healthier, more comfortable working environment for employees while enhancing the overall harmony within the community.In addition to these advantages, the Industrial Oil-Free Air Compressor offers unmatched reliability and durability. With rigorous quality control and meticulous testing procedures, the company guarantees that each compressor leaving their factory is of the highest standard. This reliability ensures minimal disruptions to the manufacturing process, safeguarding productivity and reducing costly downtime.With an unwavering commitment to customer satisfaction, the company not only provides cutting-edge technology but also offers exceptional customer service. A team of highly skilled engineers and technicians provides prompt assistance, ensuring that each client receives personalized support tailored to their unique requirements.As the industrial landscape continues to evolve, manufacturers must adapt to emerging trends and technologies to stay ahead in the competitive market. The Industrial Oil-Free Air Compressor represents the future of compressed air solutions, providing manufacturers with the means to improve productivity, reduce costs, and align with sustainable practices. With an emphasis on quality, efficiency, and environmental consciousness, this compressor is poised to transform the manufacturing industry, offering businesses a reliable and dynamic solution for their compressed air needs.About [Company]:[Company] is a pioneering force in the air compressor industry, specializing in innovative and sustainable compressed air solutions. With a global presence and a commitment to excellence, [Company] has established itself as a trusted provider of state-of-the-art compressors, catering to a diverse range of industries. By combining cutting-edge technology, extensive research, and unparalleled customer service, [Company] continues to shape the future of compressed air solutions worldwide.For media inquiries, please contact:[Contact Information]###

Screw Air Compressors: Your Solution for Air Compressing Needs

Mobile Screw Compressor – Making Air Compressing More ConvenientWhen it comes to industrial applications, air compressors are indispensable. They serve as the source of power for a lot of machines and equipment. However, like all other machines, air compressors too demand a certain level of care and maintenance. But, imagine if there was an air compressor that was not only reliable, but also mobile enough to be taken from one place to another easily. That's where the Mobile Screw Compressor comes in.With the advent of technology, the manufacturing industry has seen a lot of advancements. As a result, a lot of new and improved types of air compressors are now available in the market. But, the Mobile Screw Compressor stands out with its convenience and portability. Let us take a closer look at what a mobile screw compressor is, its features, and its benefits.What is a Mobile Screw Compressor?A Mobile Screw Compressor is a type of air compressor that is designed to be easily moved from one location to another. These compressors come equipped with wheels, handles, and other features that make it much easier to transport. They are specifically designed to cater to industries that require compressed air at several locations. These compressors are compact, efficient, easy to service, and can be powered by a variety of power sources.The Features of a Mobile Screw CompressorA Mobile Screw Compressor comes packed with a lot of features that make it a reliable and efficient choice for industries that require compressed air. Here are a few notable features:1. Compact Design – Mobile Screw Compressors have a compact design that makes it possible to transport them in areas with space restrictions.2. Extreme Mobility – With wheels and handles, it's a breeze to move the compressor from one location to another.3. Non-Stop Compressed Air – The compressor has a built-in air receiver that enables it to automatically stop and start according to the requirements.4. Noiseless Operation – The Mobile Screw Compressor is designed to operate quietly without causing any disturbance in the workplace.5. High-Quality Material – The compressor is made up of high-quality materials that guarantee durability and longevity.The Benefits of Owning a Mobile Screw CompressorA Mobile Screw Compressor offers a host of benefits to industries that require compressed air. Here are a few notable ones:1. Increased Efficiency - With the Mobile Screw Compressor, compressed air is available wherever it is required, which increases efficiency and productivity.2. Easy to Transport - Because of its compact design and mobility, the compressor can be effortlessly moved to any location.3. Improved Accessibility - A Mobile Screw Compressor can be used in remote locations that don't have access to a power source. This is because it can be powered by a range of sources including generators, trucks, and tow vehicles.4. Reduced Downtime - With the non-stop compressed air feature, there is no need to wait for the air to build up again. Tasks can be completed faster, and the overall downtime is reduced.5. Noiseless Operation - It operates quietly, whatever the work environment, resulting in a better work experience and a more harmonious environment.ConclusionThe Mobile Screw Compressor is a practical piece of equipment that is designed to make air compressing more convenient. Due to its compact design, easy mobility, and range of features, it has become the right choice for many industries which require compressed air at multiple locations. It's a durable and reliable machine that can be powered in various ways and provides non-stop compressed air to guarantee productivity and efficiency. If you're looking for a reliable and efficient air compressor, consider investing in a Mobile Screw Compressor.

New High-Quality Industrial Air Compressor Pump Released" could be rewritten to "High-Performance Industrial Air Compressor Pump Now Available".

[Your News Outlet’s Name][Date]Industrial Air Compressor Pump Sets New Industry Standard[City, State] – [Industrial Air Compressor Pump Manufacturer], a leading provider of innovative industrial solutions, has introduced their latest product, setting a new industry standard for air compressor pumps. Designed to meet the demands of the modern manufacturing sector, this revolutionary pump promises unparalleled performance and reliability.Compressed air is vital for various industries, including manufacturing, construction, and automotive. From powering tools and machinery to facilitating efficient processes, industrial air compressor pumps play a crucial role in ensuring smooth operations. With the release of their newest model, [Industrial Air Compressor Pump Manufacturer] aims to revolutionize the industry by offering a game-changing product.The [Model Name] boasts cutting-edge features that set it apart from competing air compressor pumps. Its impressive efficiency ensures maximum productivity, allowing businesses to save valuable time and resources. Equipped with advanced technology, this pump delivers a consistent, uninterrupted supply of compressed air, eliminating costly downtime and production delays.One of the key features of the [Model Name] is its robust construction. Built to withstand the rigors of heavy-duty usage, it offers exceptional durability and longevity. The pump's components are made from high-quality materials that guarantee longevity, reducing the need for frequent repairs and replacements. This not only saves businesses money but also enhances their operational efficiency.Furthermore, the [Model Name] is designed with a focus on energy efficiency. In an era characterized by sustainability and environmental responsibility, [Industrial Air Compressor Pump Manufacturer] demonstrates their commitment to reducing carbon footprints. The pump incorporates state-of-the-art technology that maximizes energy utilization without compromising performance. This not only helps businesses become more eco-friendly but also delivers substantial cost savings by reducing electricity consumption.Ease of use is another standout feature of the [Model Name]. The user-friendly interface and intuitive controls ensure that operators can quickly familiarize themselves with the pump, minimizing training time and potential errors. Additionally, its compact size and modular design allow for easy installation and maintenance, simplifying the overall process.[Industrial Air Compressor Pump Manufacturer], a renowned industry player, has a long-standing reputation for delivering excellence. With this latest innovation, they continue to uphold their commitment to pushing the boundaries of technological advancement. By prioritizing customer needs and investing in research and development, they have consistently been at the forefront of industry trends and customer satisfaction.In addition to its remarkable features, the [Model Name] is backed by [Industrial Air Compressor Pump Manufacturer]'s unmatched customer service. Their team of highly skilled technicians and engineers provides comprehensive support, ensuring that clients get prompt assistance whenever needed. This commitment to after-sales service ensures that customers receive the maximum value from their investment.The arrival of the [Model Name] has created a buzz among industry insiders and professionals. Early adopters who have had the opportunity to test the pump praise its performance and reliability, hailing it as a significant game-changer in the industry. Companies across various sectors are eagerly awaiting the chance to integrate the [Model Name] into their operations and experience the benefits firsthand.With its revolutionary capabilities, exceptional durability, energy efficiency, and outstanding customer support, the [Model Name] establishes itself as the go-to air compressor pump in the market. [Industrial Air Compressor Pump Manufacturer] cements its position as an industry leader, solidifying their commitment to innovation and customer satisfaction.For more information about the [Model Name] and other products offered by [Industrial Air Compressor Pump Manufacturer], please visit their website [website URL] or reach out to their dedicated customer service team at [customer service contact]. Experience the future of industrial air compressor pumps with [Industrial Air Compressor Pump Manufacturer].