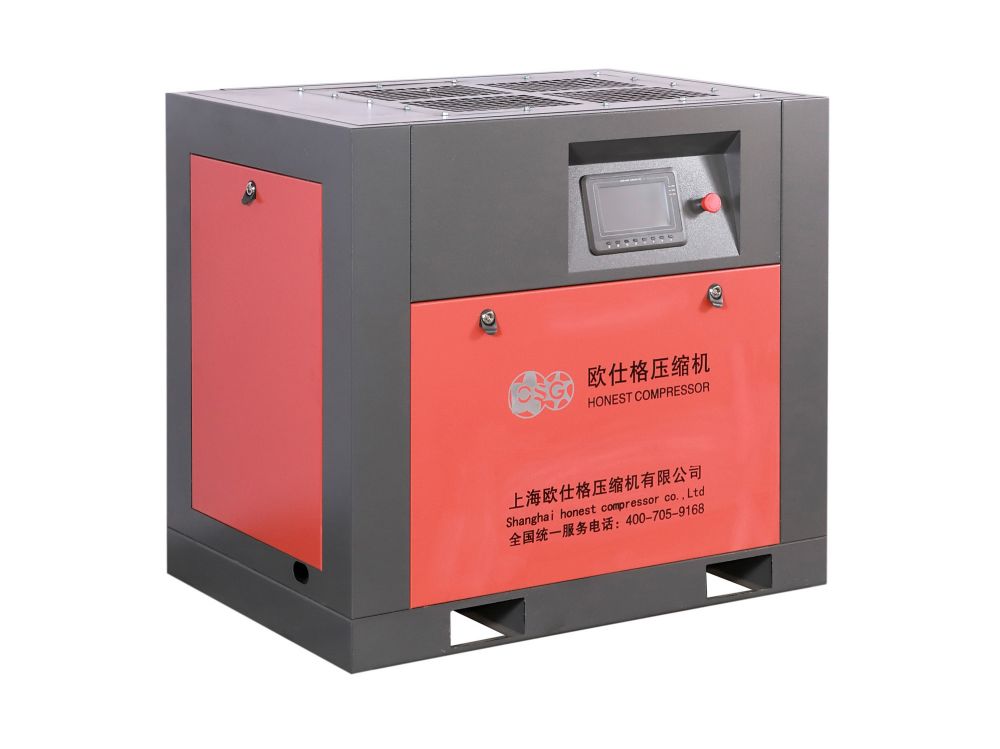

Highly Efficient Mini Screw Compressor for Various Applications

By:Admin

The Mini Screw Compressor is a compact and efficient compressor that is designed to deliver reliable performance in a variety of industrial settings. Whether it's for power generation, oil and gas, or manufacturing, the Mini Screw Compressor is built to handle the demands of modern industry.

One of the key features of the Mini Screw Compressor is its compact size. This makes it an ideal choice for businesses with limited space, as it can be easily integrated into existing production lines without the need for major modifications. Despite its small footprint, the Mini Screw Compressor is capable of delivering high levels of compressed air, making it a versatile and cost-effective solution for businesses of all sizes.

In addition to its compact size, the Mini Screw Compressor is also known for its energy efficiency. With a focus on sustainability and environmental responsibility, the company has designed the compressor to minimize energy consumption while maximizing performance. This not only helps businesses reduce their carbon footprint, but also lowers operating costs in the long term.

Furthermore, the Mini Screw Compressor is built to last. Using high-quality materials and precision engineering, the company ensures that its compressors are durable and reliable, even in the toughest industrial environments. This commitment to quality and reliability has made the Mini Screw Compressor a trusted choice for businesses that depend on consistent compressed air supply for their operations.

The company behind the Mini Screw Compressor has a strong reputation for customer service and support. With a global network of distributors and service centers, businesses can rely on the company to provide timely maintenance and repairs for their compressors. This level of support gives businesses the peace of mind that their compressed air supply is in good hands, allowing them to focus on their core operations without worrying about equipment downtime.

In addition to its standard range of compressors, the company also offers custom solutions to meet the specific needs of its clients. Whether it's a unique size, capacity, or special requirements, the company's team of engineers and technical experts can work with businesses to develop a tailored compressor solution that fits their exact specifications. This level of flexibility and customization sets the company apart from its competitors, making it a preferred choice for businesses with unique compressed air requirements.

Overall, the Mini Screw Compressor and the company behind it are dedicated to providing reliable, efficient, and high-quality compression solutions for businesses around the world. With a focus on innovation, sustainability, and customer satisfaction, the company continues to lead the way in the industry, setting new standards for compressed air technology and performance.

With a track record of success and a commitment to excellence, the Mini Screw Compressor is a name that businesses can trust for their compressed air needs. Whether it's for industrial manufacturing, energy production, or any other application, the company's compressors are designed to deliver reliable performance and value for their customers.

As businesses continue to evolve and adapt to new challenges, the Mini Screw Compressor and its parent company are well-positioned to provide the cutting-edge compression solutions that businesses need to stay ahead. With a focus on quality, innovation, and customer satisfaction, the company is poised to remain a leader in the industry for years to come.

Company News & Blog

Powerful Screw Compressor with 30 Horsepower for Industrial Use

{Company Name} is proud to introduce the latest addition to its product line - the 30 Hp screw compressor. This powerful and efficient compressor is set to revolutionize the industry with its cutting-edge technology and high performance.The 30 Hp screw compressor is designed for industrial applications where high reliability and low maintenance are essential. With a compact and space-saving design, this compressor provides a reliable source of compressed air for a wide range of manufacturing and industrial processes.The key feature of this compressor is its advanced screw technology, which ensures consistent and reliable performance. The screw compressor is known for its high efficiency and reliability, making it a preferred choice for industrial applications.One of the key benefits of the 30 Hp screw compressor is its energy efficiency. With rising energy costs, companies are increasingly looking for ways to reduce their energy consumption and carbon footprint. The screw compressor is designed to operate at optimal efficiency, resulting in significant energy savings for the end user.In addition to its energy efficiency, the 30 Hp screw compressor is also known for its low maintenance requirements. With fewer moving parts and a simple design, this compressor is easy to service and maintain, reducing downtime and increasing productivity for the end user.The 30 Hp screw compressor is also equipped with advanced monitoring and control systems, allowing for real-time performance tracking and remote diagnostics. This ensures that the compressor operates at its optimal performance level at all times, reducing the risk of unexpected downtime and costly repairs.With a robust construction and high-quality components, the 30 Hp screw compressor is built to withstand the rigors of industrial use. Its durable design and reliable performance make it a valuable asset for any industrial operation.The 30 Hp screw compressor is also designed with safety in mind. With advanced safety features and built-in protection systems, this compressor provides peace of mind for operators and maintenance personnel, ensuring a safe working environment.From automotive manufacturing to food processing, the 30 Hp screw compressor is suitable for a wide range of industrial applications. Its versatility and high performance make it an ideal choice for companies looking to optimize their operations and enhance productivity.As a leading provider of industrial equipment, {Company Name} is proud to offer the 30 Hp screw compressor as part of its comprehensive product range. With a focus on innovation and quality, the company continues to deliver reliable and cutting-edge solutions to meet the evolving needs of the industry.With its advanced technology, energy efficiency, and low maintenance requirements, the 30 Hp screw compressor is set to make a significant impact in the industrial sector. Its reliable performance and versatility make it a valuable asset for companies looking to streamline their operations and improve their bottom line.In conclusion, the introduction of the 30 Hp screw compressor represents a significant milestone for {Company Name} and the industry as a whole. With its advanced technology and high performance, this compressor is set to redefine the standards for reliability, efficiency, and productivity in the industrial sector. As companies continue to seek innovative solutions to enhance their operations, the 30 Hp screw compressor is poised to become a preferred choice for industrial applications around the world.

10 Benefits of Using a Permanent Magnet Screw Compressor for Industrial Applications

[Company Name] Launches Revolutionary Permanent Magnet Screw Compressor Redefining Industry Standards[City, Date]In a significant breakthrough that promises to reshape the industrial machinery sector, [Company Name], a global leader in engineering and manufacturing, has unveiled its latest innovation – the Permanent Magnet Screw Compressor. Built on years of research and development, this cutting-edge technology sets the stage for a new era of efficiency, performance, and reliability.The Permanent Magnet Screw Compressor stands out among its counterparts due to the incorporation of advanced permanent magnet motor technology. This revolutionary feature delivers unmatched energy efficiency, offering significant cost savings and an eco-friendly solution to industries relying on compressed air systems for their operations.[Company Name], known for its commitment to innovative engineering, has been a prominent player in the industrial machinery sector for several decades. With a track record of delivering high-quality products, the company has successfully established itself as a trusted partner in meeting the unique needs of various industries across the globe. Now, with the launch of the Permanent Magnet Screw Compressor, [Company Name] aims to further bolster its reputation as an industry leader.The Permanent Magnet Screw Compressor leverages the power of permanent magnets to provide precise and variable speed control. This ensures that the compressor operates at optimal efficiency regardless of varying demands. By accurately matching the compressed air supply to the actual demand, energy wastage is reduced, resulting in a significant decrease in operating costs.Furthermore, with its compact and space-saving design, the Permanent Magnet Screw Compressor maximizes efficiency without compromising on performance. It enables industries to reduce their carbon footprint by slashing energy consumption and lowering greenhouse gas emissions. By embracing this innovative technology, businesses can not only achieve their sustainability goals but also comply with stringent environmental regulations.One of the key advantages of the Permanent Magnet Screw Compressor is its ability to deliver consistent pressure and air quality. The advanced control system ensures stable operation, minimizing downtime and maximizing productivity even in demanding industrial environments. This level of reliability is crucial for industries such as manufacturing, automotive, aerospace, and food processing, where uninterrupted compressed air is essential for critical operations.To ensure the highest standard of quality, [Company Name] employs rigorous testing and state-of-the-art manufacturing processes in the production of the Permanent Magnet Screw Compressor. Thorough reliability tests and quality control measures are implemented at every stage, making certain that each unit meets industry standards and exceeds customer expectations.Additionally, [Company Name] provides comprehensive after-sales support to its customers, including regular maintenance and technical assistance. A dedicated team of highly skilled professionals is available 24/7 to address any concerns and ensure optimal performance of the Permanent Magnet Screw Compressor throughout its service life.The impact of the Permanent Magnet Screw Compressor extends beyond efficiency and reliability. Its ability to deliver significant energy savings directly contributes to the sustainable development goals laid out by governments and international organizations globally. By reducing energy consumption and carbon emissions, this groundbreaking technology aligns with the growing emphasis on environmental stewardship and corporate social responsibility.With the launch of the Permanent Magnet Screw Compressor, [Company Name] reaffirms its commitment to driving innovation in the industrial machinery sector. By redefining industry standards and providing an energy-efficient solution, [Company Name] aims to empower businesses to optimize their operations, achieving a competitive edge in the increasingly demanding market.Through a combination of cutting-edge technology, exceptional build quality, and unmatched customer support, [Company Name] continues to trailblaze the path towards a more sustainable and efficient future for the industrial machinery sector.

Innovative Air Dryer System: A Game Changer for Drying Technology

Air Dryer System Helps Company Improve Efficiency and SustainabilityIn today’s fast-paced and competitive business world, companies are constantly seeking ways to improve their efficiency and sustainability. One important aspect of this effort is the management of the company’s air quality, particularly in manufacturing and industrial settings. This is where the innovative Air Dryer System offered by {Company Name} comes into play, helping companies to improve their operations and reduce their environmental footprint.{Company Name} has been a leading supplier of air quality management solutions for over 20 years, serving a wide range of industries including automotive, food and beverage, pharmaceuticals, and more. The company is committed to providing high-quality, cost-effective, and environmentally friendly solutions to its customers, and the Air Dryer System is a prime example of this commitment.The Air Dryer System is designed to remove moisture and contaminants from compressed air, ensuring that the air used in industrial processes is clean, dry, and free from impurities. This is crucial for maintaining the efficiency and reliability of pneumatic equipment, as well as for ensuring the quality of manufactured products. By removing moisture from compressed air, the Air Dryer System helps to prevent corrosion and fouling in equipment, reducing maintenance costs and downtime.Furthermore, the Air Dryer System also contributes to the sustainability efforts of companies by reducing energy consumption. By removing moisture from compressed air, the system helps to improve the efficiency of pneumatic equipment, reducing the amount of energy needed to operate it. This not only helps companies to save on energy costs, but it also reduces their overall greenhouse gas emissions, contributing to a more sustainable and environmentally friendly operation.One of {Company Name}’s latest success stories involves a partnership with a leading automotive manufacturer that was facing challenges with moisture-related issues in their painting process. The company’s painting equipment was experiencing frequent breakdowns and quality issues, resulting in costly rework and delays in production. After implementing the Air Dryer System, the automotive manufacturer saw a significant improvement in their operations. The system effectively removed moisture from the compressed air used in the painting process, resulting in a reduction in equipment breakdowns and improved paint quality. This not only saved the company money in maintenance and rework costs, but also resulted in increased productivity and customer satisfaction.The success of the Air Dryer System has been further demonstrated in the food and beverage industry, where companies have utilized the system to maintain the quality and safety of their products. By ensuring that compressed air is free from contaminants, the system helps to meet the strict hygiene and safety standards of the industry, while also improving the efficiency and reliability of production processes.{Company Name} takes pride in its ability to provide customized air quality solutions to meet the specific needs and challenges of each customer. With a team of experienced engineers and technicians, the company works closely with its clients to assess their air quality requirements and develop tailored solutions to address them. This customer-centric approach has earned {Company Name} a reputation for reliability and excellence in the industry.Looking ahead, {Company Name} remains committed to innovation and continuous improvement in its air quality management solutions. The company is constantly seeking new ways to enhance the performance and sustainability of its products, ensuring that it remains at the forefront of the industry.In conclusion, the Air Dryer System offered by {Company Name} has proven to be an invaluable asset for companies seeking to improve their efficiency and sustainability. By removing moisture and contaminants from compressed air, the system helps to reduce maintenance costs, improve equipment reliability, and increase energy efficiency. As companies continue to prioritize sustainability and environmental responsibility, the Air Dryer System stands as a testament to the crucial role of air quality management in achieving these goals. With its track record of success and commitment to excellence, {Company Name} remains a trusted partner for businesses seeking reliable and cost-effective air quality solutions.

Compact and Portable Screw Compressor for Versatile Use

[Company Name], a leading manufacturer of industrial machinery, has recently introduced a new portable screw compressor to their product lineup. This state-of-the-art compressor is designed to provide reliable and efficient compressed air solutions for a wide range of industrial applications.The new portable screw compressor from [Company Name] is the result of years of research and development, aimed at creating a versatile and high-performance machine that meets the needs of modern industries. The compressor is compact and lightweight, making it easy to transport and install in various working environments. Its portable design allows for flexibility and convenience, making it an ideal choice for mobile and remote operations.One of the key features of the new portable screw compressor is its powerful and energy-efficient motor. This motor is designed to deliver consistent and high-quality compressed air, while minimizing energy consumption and operating costs. This makes the compressor an environmentally friendly and cost-effective solution for businesses looking to reduce their carbon footprint and save on energy expenses.The compressor also comes equipped with advanced control systems, allowing for precise adjustment of air pressure and flow to meet specific requirements. This level of control ensures optimal performance and reliability, while also extending the lifespan of the compressor and reducing maintenance needs.In addition to its cutting-edge technology and superior performance, the new portable screw compressor from [Company Name] is also designed with user-friendliness in mind. Its intuitive interface and ergonomic design make it easy to operate and maintain, while its robust construction ensures durability and longevity even in demanding industrial settings.The portable screw compressor is available in various models and configurations, allowing businesses to choose the right machine for their specific needs. Whether it’s for construction, manufacturing, oil and gas, or other industrial applications, the new compressor offers a versatile and dependable solution for generating compressed air on the go.“At [Company Name], we are committed to providing innovative and reliable solutions for our customers’ compressed air needs,” said a spokesperson for the company. “The introduction of our new portable screw compressor is a testament to our dedication to delivering cutting-edge technology and superior performance in all our products.”With the launch of the new portable screw compressor, [Company Name] continues to solidify its position as a leading provider of compressed air solutions for industrial applications. The company’s extensive experience and expertise in the industry, combined with its commitment to innovation and quality, make it a trusted partner for businesses around the world.To learn more about the new portable screw compressor from [Company Name] and explore their complete range of industrial machinery and equipment, visit their website or contact their sales team for personalized assistance. As industries continue to evolve and demand more efficient and reliable compressed air solutions, [Company Name] remains at the forefront, offering state-of-the-art products and unparalleled support to help businesses thrive and succeed.

Benefits of using an Air Dryer for Compressed Air

In today's world, air dryers have become an integral part of numerous industries. Every industry uses compressed air systems for various applications, such as pneumatics, drying, and conveying. However, compressed air contains moisture that can compromise the quality of the system's air. This moisture can lead to corrosion, leaks, and other operational issues.To combat these challenges, various types of air dryers are available on the market. One such type is the refrigerated air dryer, which cools the compressed air to a dew point where the moisture condenses and can be removed. The advantage of the refrigerated air dryer is its cost-effectiveness and ability to dry air to a dew point that is suitable for many applications. Another type of air dryer is the desiccant air dryer, which uses a drying agent to absorb moisture from the compressed air. This type of air dryer is ideal for applications that require very dry compressed air because it can achieve a dew point as low as -100°F. In addition to these two types of air dryers, there are other solutions available, such as the membrane air dryer that works by separating moisture through a selective permeable membrane and the deliquescent air dryer that uses a salt-based drying agent to absorb moisture. One company that is well-known for its innovative air drying solutions is [Company Name]. The company offers a wide range of air dryers for various applications, including refrigerated air dryers, desiccant air dryers, and membrane air dryers. [Company Name]'s air dryers are designed to provide high-quality compressed air and cater to the diverse requirements of different industries. The company's team of experts work diligently to design, manufacture, and test air dryers to ensure optimal performance, reliability, and durability. The company's refrigerated air dryer series provides an efficient solution for drying compressed air with low to medium flow rates. These air dryers are designed with energy efficiency in mind, enabling them to provide cost-saving benefits to the customer. [Company Name] also offers a desiccant air dryer series that provides clean, dry air ideal for critical applications. These air dryers are designed to handle high flow rates, ensuring that they meet the demanding requirements of industries such as pharmaceuticals, food, and beverage. Further, the company's membrane air dryer series is ideal for customers who require clean and dry compressed air in remote locations where electricity supply is not available. These air dryers are compact, portable, and low-maintenance, making them perfect for different types of field applications. [Company Name] also offers customized solutions that cater to unique customer requirements. The company's team of engineers works closely with customers to design an air drying solution that meets their specific needs. This means that [Company Name] can deliver the perfect air drying solution for any application, whether for simple or complex requirements. The company's commitment to quality is evident in its stringent quality control procedures. All [Company Name]'s air dryers undergo rigorous testing to ensure that each air dryer meets the highest standards. Customer satisfaction is a top priority for the company, and this is ensured with the provision of documentation, installation, and commissioning services, as well as reliable after-sales support. In conclusion, air dryers play a crucial role in many industries by ensuring the delivery of clean, dry compressed air. [Company Name] offers a broad range of air drying solutions that cater to various requirements and applications. The company's commitment to quality, reliability, and customer satisfaction is evident in its products and services. [Company Name] is sure to be a top choice for customers seeking high-quality air drying solutions.

Screw Air Compressor With Integrated Dryer: The Ultimate Solution for Your Industrial Needs

Screw Air Compressor With Dryer Provides Reliable and Efficient Compressed Air SolutionsIn the world of manufacturing and industrial operations, having a reliable source of compressed air is essential for efficiency and productivity. To meet this need, [Company Name] has introduced a high-performance screw air compressor with a built-in dryer that provides a seamless and efficient compressed air solution for a wide range of applications.The screw air compressor with a dryer is designed to deliver a constant and reliable source of compressed air while also effectively removing moisture from the air to ensure optimal performance. This innovative product is the result of years of research and development, and it is a testament to [Company Name]'s commitment to delivering cutting-edge solutions to its customers.With a focus on energy efficiency and reliability, the screw air compressor with dryer is equipped with advanced features that set it apart from traditional compressed air systems. The compressor is designed to minimize energy consumption while also maximizing performance, making it an ideal choice for businesses looking to reduce their carbon footprint and operating costs.One of the key benefits of the screw air compressor with a dryer is its compact design, which allows for easy installation and integration into existing air supply systems. This means that businesses can upgrade their compressed air infrastructure without the need for extensive modifications or downtime, resulting in a seamless transition to a more efficient and reliable compressed air solution.Furthermore, the built-in air dryer is a crucial component of the screw air compressor, as it effectively removes moisture from the compressed air, preventing corrosion and contamination of pneumatic equipment and ensuring the quality of the air supply. This feature is especially important for businesses operating in humid or moist environments, as it helps to prolong the lifespan of pneumatic tools and equipment.In addition to its reliable performance and energy efficiency, the screw air compressor with a dryer is also equipped with advanced controls and monitoring systems that allow for easy operation and maintenance. This means that businesses can effectively manage and optimize their compressed air supply, leading to improved productivity and cost savings in the long run.[Company Name] has built a reputation for delivering high-quality compressed air solutions to businesses across various industries. With a focus on innovation and customer satisfaction, the company has positioned itself as a leader in the field of compressed air technology, and the introduction of the screw air compressor with a dryer is a testament to its ongoing commitment to excellence.As a customer-centric company, [Company Name] offers comprehensive support and after-sales service for its products, ensuring that businesses can rely on their compressed air solutions for years to come. Whether it's installation, maintenance, or technical support, [Company Name] is dedicated to providing its customers with the highest level of service and expertise.In conclusion, the introduction of the screw air compressor with a dryer from [Company Name] represents a significant advancement in compressed air technology. With its reliable performance, energy efficiency, and advanced features, this innovative product is poised to provide businesses with a seamless and efficient compressed air solution for a wide range of applications. As the demand for reliable and high-performance compressed air solutions continues to grow, [Company Name] is well-positioned to meet the needs of its customers and lead the way in the industry.

Ultimate Guide to Screw AC Compressor Installation and Maintenance

Screw AC Compressor, WeNn Inc. Introduces New Line of Energy-Efficient Compressor SolutionsWeNn Inc. is proud to announce the launch of its latest line of energy-efficient screw AC compressors. The new range of compressors boasts cutting-edge technology and innovative engineering, positioning WeNn Inc. as a leader in the field of air conditioning and refrigeration.The screw AC compressors are designed to meet the growing demand for energy-efficient cooling solutions in residential, commercial, and industrial spaces. With a focus on sustainability and environmental responsibility, WeNn Inc. has developed a range of compressors that not only deliver exceptional performance but also reduce energy consumption and operational costs.The new line of screw AC compressors features state-of-the-art variable speed drive technology, allowing for precise control of the compressor speed based on the cooling load. This results in significant energy savings, as the compressors adjust their output to match the specific cooling requirements, thereby minimizing energy wastage.In addition to their energy-efficient operation, WeNn Inc.'s screw AC compressors are also designed for durability and reliability. The compressors are built to withstand the rigors of continuous operation, delivering consistent performance even in demanding operating conditions. This ensures minimal downtime and maintenance, contributing to overall operational efficiency and cost savings for customers."We are excited to introduce our new line of screw AC compressors, which represent a significant advancement in energy-efficient cooling technology," said the CEO of WeNn Inc. "With a focus on sustainability and performance, these compressors are well-suited for a wide range of applications, from residential air conditioning to large-scale industrial refrigeration systems."WeNn Inc. is known for its commitment to innovation and quality, and the new line of screw AC compressors is a testament to the company's dedication to excellence. By leveraging the latest advancements in compressor technology, WeNn Inc. aims to provide customers with reliable, cost-effective, and environmentally friendly cooling solutions that meet their specific needs.The launch of the new screw AC compressors underscores WeNn Inc.'s position as a leading provider of air conditioning and refrigeration solutions. With a track record of delivering high-performance products and exceptional customer service, WeNn Inc. continues to set industry standards and drive innovation in the field of cooling technology.As the demand for energy-efficient and environmentally friendly cooling solutions continues to grow, WeNn Inc. is well-positioned to meet the evolving needs of customers across various sectors. The company's new line of screw AC compressors is poised to make a significant impact in the market, offering a compelling combination of performance, efficiency, and reliability.WeNn Inc. remains committed to advancing the state of the art in air conditioning and refrigeration technology, and the introduction of the new screw AC compressors is a testament to the company's ongoing pursuit of excellence. With a focus on sustainability, performance, and customer satisfaction, WeNn Inc. looks forward to serving the needs of customers with its latest line of energy-efficient compressor solutions.

Benefits of Refrigerant Dryers: Maximizing Efficiency and Reducing Moisture

Title: Innovating the Future of Air Compressors: Refrigerant Dryer Revolutionizes Moisture ControlSubtitle: Leading the Way in High-Quality and Efficient Air Compression TechnologyIntroduction (100 words):With a strong commitment to innovation and quality, [Company Name] continues to revolutionize the air compression industry by introducing its groundbreaking Refrigerant Dryer. This cutting-edge technology not only improves the overall performance of air compressors but also ensures optimum moisture control, paving the way for enhanced productivity in various industrial applications. The [Company Name] Refrigerant Dryer is designed to meet the diverse needs of global customers by providing energy-efficient solutions that reduce operational costs while improving the quality and durability of compressed air equipment. Let's delve deeper into its features and benefits.1. Moisture Control Reinvented (150 words):[Pronoun/Company Name]'s Refrigerant Dryer is a game-changer when it comes to controlling moisture and ensuring clean, dry compressed air. Unlike traditional air dryers, the innovative design of the Refrigerant Dryer minimizes the risk of condensation forming within air compressors, pipelines, and other pneumatic tools. This breakthrough technology prevents costly damage to equipment and avoids potential downtime due to moisture-related issues in industrial operations.By utilizing advanced refrigeration principles, the Refrigerant Dryer effectively removes water vapor and impurities from the compressed air, resulting in air of exceptional quality. This process protects downstream equipment from corrosion, enhances productivity, and extends the lifespan of air compressors and tools.2. Energy Efficiency Saves Costs (150 words):In line with its commitment to sustainability, [Company Name] Refrigerant Dryer is engineered to be highly energy-efficient. By employing state-of-the-art technology such as intelligent humidity controls and variable-speed fans, the dryer optimizes power consumption while delivering superior performance. This energy-saving feature significantly reduces operational costs, positively impacting a company's bottom line.Additionally, the Refrigerant Dryer's user-friendly interface allows for simple control and monitoring of the drying process, further enhancing efficiency. Operators can easily adjust settings and access real-time data for maintenance and energy optimization, making the [Company Name] Refrigerant Dryer an invaluable asset for any industrial setting.3. Versatility and Adaptability (150 words):The [Company Name] Refrigerant Dryer stands out for its versatility and adaptability in meeting the unique requirements of various industries. Its modular design and flexible installation options ensure seamless integration into existing compressed air systems, regardless of size or complexity. This adaptability allows businesses to enhance their operations without significant modifications, reducing downtime and increasing overall efficiency.Furthermore, the Refrigerant Dryer is engineered to handle varying airflow rates and ambient conditions, providing consistent and efficient moisture control even in demanding environments. With adjustable dew point levels, the dryer can cater to a wide range of applications, including manufacturing, pharmaceuticals, electronics, food and beverage, and much more.4. Reliability and Durability (150 words):When it comes to durability and reliability, the [Company Name] Refrigerant Dryer sets the benchmark. Built with high-quality materials and subjected to rigorous testing, this industry-leading innovation guarantees robust performance and long-lasting service. Its advanced filtration systems ensure the removal of harmful contaminants, safeguarding delicate equipment and sensitive processes from potential damage.By preventing the accumulation of moisture, which could lead to corrosion and system failure, the Refrigerant Dryer significantly reduces maintenance costs and downtime, providing businesses with a dependable and uninterrupted air compression solution.Conclusion (100 words):As air compressors play a vital role in countless industries, moisture control remains essential for safeguarding equipment and maximizing productivity. The [Company Name] Refrigerant Dryer redefines the standards by combining cutting-edge technology, energy efficiency, versatility, and durability in one state-of-the-art package. Its ability to remove moisture and impurities from compressed air ensures uninterrupted performance, enabling businesses to achieve optimal results while reducing operational costs. [Company Name], through its relentless pursuit of excellence, has once again solidified its position as a trusted and innovative leader in the air compression industry.

Ultimate Guide to Choosing a Pressure Dryer: What You Need to Know

[Company Name] Introduces Innovative Pressure Dryer for Efficient Drying Solutions[City, State] – [Company Name], a leading manufacturer of industrial equipment, has recently introduced a new and innovative pressure dryer designed to provide efficient drying solutions for a wide range of industries. The [Company Name] Pressure Dryer is a state-of-the-art machine that utilizes advanced technology to deliver fast and effective drying results for various materials and products.The [Company Name] Pressure Dryer is the latest addition to the company's extensive line of industrial equipment, and it is expected to set new standards in the field of drying technology. With its cutting-edge features and high-performance capabilities, the pressure dryer is poised to revolutionize the way industries approach the drying process.One of the key features of the [Company Name] Pressure Dryer is its ability to efficiently remove moisture from materials while maintaining their integrity and quality. This is particularly important for industries such as pharmaceuticals, food processing, and chemical manufacturing, where the preservation of product quality is of utmost importance. The pressure dryer is designed to handle materials with precision, ensuring that they are thoroughly dried without compromising their structural and chemical properties.In addition to its exceptional drying capabilities, the [Company Name] Pressure Dryer also offers a user-friendly interface and intuitive controls, making it easy to operate and monitor. The machine is equipped with advanced sensors and automation technology, allowing for precise control over the drying process and ensuring consistent results every time. This level of automation not only streamlines the drying process but also reduces the need for manual intervention, thereby increasing overall efficiency and productivity.Another noteworthy aspect of the [Company Name] Pressure Dryer is its energy-efficient design, which helps to minimize operational costs and environmental impact. The machine features advanced heating and airflow systems that are optimized for maximum efficiency, resulting in lower energy consumption and reduced carbon emissions. This makes the pressure dryer an environmentally friendly solution for industries seeking to enhance their sustainability practices.Furthermore, the [Company Name] Pressure Dryer is built with durability and reliability in mind, featuring a robust construction and high-quality components that are designed to withstand heavy-duty use. This ensures a long service life for the machine, allowing industries to benefit from its drying capabilities for years to come. Additionally, the pressure dryer is backed by [Company Name]'s comprehensive warranty and customer support, providing peace of mind to users and ensuring their continued satisfaction with the product.The introduction of the [Company Name] Pressure Dryer represents a significant milestone for the company, as it further solidifies [Company Name]'s position as a leading provider of innovative industrial solutions. With its unparalleled performance, user-friendly design, and energy-efficient operation, the pressure dryer is poised to make a lasting impact on the industry and set new benchmarks for drying technology.[Company Name] is committed to delivering cutting-edge solutions that enhance the efficiency and productivity of industries worldwide. The introduction of the pressure dryer is a testament to [Company Name]'s dedication to innovation and its unwavering commitment to meeting the evolving needs of its customers.In conclusion, the [Company Name] Pressure Dryer is set to redefine the standards of industrial drying, offering a compelling combination of performance, efficiency, and reliability. With its advanced technology and user-friendly features, the pressure dryer is poised to become the go-to solution for industries seeking superior drying solutions. As [Company Name] continues to lead the way in industrial innovation, the introduction of the pressure dryer marks a significant advancement in the company's quest to empower industries with cutting-edge solutions.

Ultimate Guide to the Power and Efficiency of 3 Phase Screw Compressors

XYZ Company Launches Innovative 3 Phase Screw Compressor for Improved Efficiency and Reliability[City], [Country] - XYZ Company, a leading provider of industrial air compressor solutions, has recently unveiled its latest innovation in the field of compressed air technology, the 3 Phase Screw Compressor. This cutting-edge compressor is designed to offer enhanced efficiency and reliability in various industrial applications.Compressed air is an essential utility in numerous industries, including manufacturing, automotive, construction, and pharmaceuticals. It is used for powering pneumatic tools, operating machinery, and even in spray painting applications. However, traditional compressors often face issues such as high energy consumption, maintenance requirements, and unstable air pressure. In response to these challenges, XYZ Company has developed the 3 Phase Screw Compressor, a game-changing solution that aims to address these pain points.The new 3 Phase Screw Compressor is built upon years of research, development, and expertise in the field of compressed air technology. It incorporates advanced features and technologies that set it apart from conventional compressors, providing customers with a more dependable and efficient solution.One of the key features of the 3 Phase Screw Compressor is its energy-saving capabilities. By utilizing advanced motor technology and intelligent control systems, the compressor minimizes energy consumption, resulting in significant cost savings for businesses. In addition, the compressor's high-efficiency cooling system ensures optimal performance while keeping operating costs low.Reliability is another paramount aspect of the 3 Phase Screw Compressor. The compressor is designed to deliver consistent and stable air pressure, vital for applications that require a reliable power source. XYZ Company has implemented state-of-the-art components and a robust build quality to ensure longevity and minimal downtime. With its low maintenance requirements, the 3 Phase Screw Compressor offers businesses increased productivity and reduced operational costs.Moreover, the 3 Phase Screw Compressor from XYZ Company is designed with user-friendly features, making it easy to operate and maintain. The intuitive control panel allows for effortless monitoring and adjustment of air pressure, ensuring optimal performance at all times. The compact design of the compressor also enables it to fit into tight spaces, reducing the need for extensive modifications to existing layouts.To ensure the highest quality and performance standards, XYZ Company subjects each 3 Phase Screw Compressor to rigorous testing and quality control procedures. The company's team of experts ensures that every unit delivers exceptional performance, reliability, and efficiency. Customers can therefore trust XYZ Company to provide them with a reliable and robust solution for their compressed air needs.Speaking about the launch of the 3 Phase Screw Compressor, [Name], the spokesperson for XYZ Company, said, "We are excited to introduce our latest innovation in compressed air technology, the 3 Phase Screw Compressor. This compressor embodies our commitment to delivering high-quality products that offer unmatched reliability and efficiency. We believe that this game-changing technology will revolutionize the way industries utilize compressed air, ultimately fostering improved productivity and profitability."XYZ Company is renowned for its dedication to innovation and delivering cutting-edge industrial air compressor solutions. With the launch of the 3 Phase Screw Compressor, the company continues to push the boundaries of compressed air technology, providing customers with products that meet their evolving needs and industry standards.In conclusion, XYZ Company's launch of the 3 Phase Screw Compressor represents a significant development in compressed air technology. The compressor's energy-saving features, reliability, and user-friendly design make it an ideal choice for industries seeking optimal performance and efficiency. With this innovative solution, XYZ Company reaffirms its position as a leader in providing high-quality compressed air solutions.