Highly efficient 5hp screw air compressor - a powerful and reliable solution

By:Admin

In the world of industrial machinery and manufacturing, reliable and efficient air compression is an essential component to the smooth operation of various processes. This is why the introduction of the 5hp screw air compressor by (company name) has caused a significant stir in the industry. This innovative piece of equipment promises to revolutionize the way companies approach air compression, offering enhanced performance and reliability.

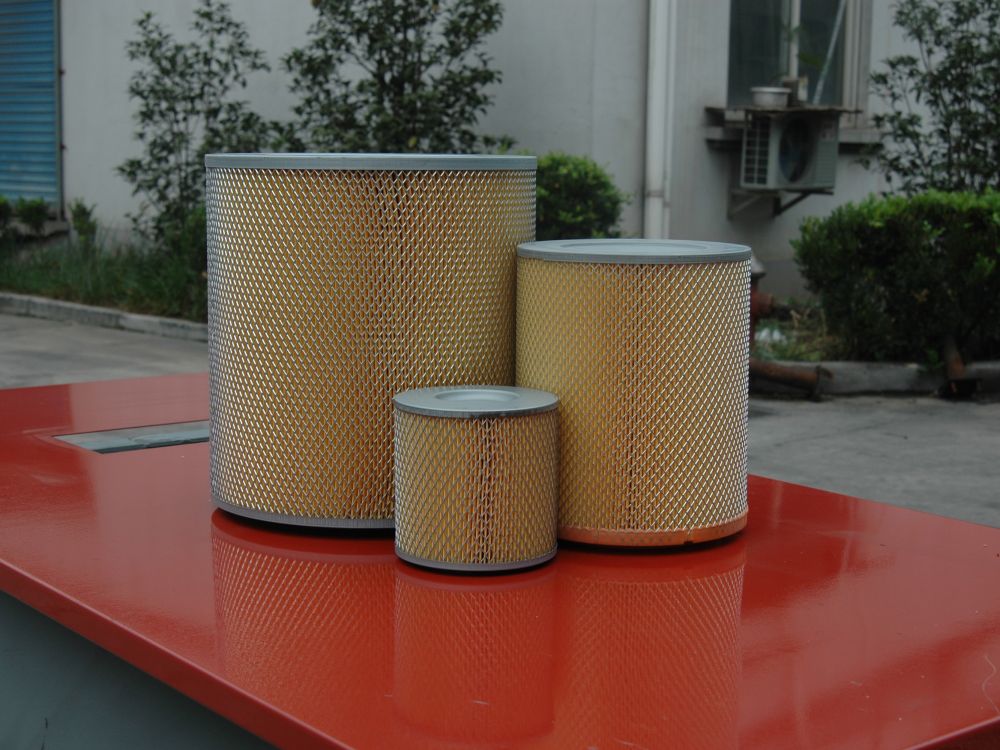

The 5hp screw air compressor is a compact and powerful machine designed to meet the needs of a wide range of industrial applications. Its screw technology allows for continuous and reliable air compression, ensuring a steady supply of compressed air to power various tools and machinery. With a compact design and low noise operation, this compressor is an ideal choice for facilities with limited space and noise regulations.

One of the key features of the 5hp screw air compressor is its energy efficiency. The machine is equipped with advanced technology that minimizes energy consumption without compromising on performance. This not only reduces operational costs for the company but also contributes to a more sustainable and environmentally friendly operation.

In addition to its energy-efficient design, the 5hp screw air compressor is also remarkably easy to maintain. The company has integrated innovative maintenance features into the machine, making it simple for operators to perform routine upkeep and repairs. This ensures minimal downtime and maximizes the lifespan of the compressor, offering long-term reliability and performance.

The introduction of this new compressor is a result of the company's commitment to innovation and customer satisfaction. As a leading manufacturer of industrial equipment, (company name) has a long-standing reputation for delivering high-quality and reliable machinery to its customers. With a focus on research and development, the company continuously seeks to improve its products and stay ahead of industry trends.

"We are thrilled to introduce the 5hp screw air compressor to the market," says (company spokesperson). "This machine represents a significant advancement in air compression technology, offering our customers a reliable and efficient solution for their industrial needs. We believe that this compressor will have a positive impact on the way companies approach air compression, and we are excited to see the benefits it brings to our customers."

The 5hp screw air compressor is already generating significant interest among industrial manufacturers and machinery operators. Many companies are expressing their eagerness to integrate this new technology into their operations, citing its energy efficiency, reliability, and ease of maintenance as key selling points.

As the industrial sector continues to evolve, the demand for reliable and efficient air compression solutions is only expected to grow. The 5hp screw air compressor by (company name) is poised to meet this demand head-on, offering a cutting-edge solution that addresses the needs of modern industrial operations.

In conclusion, the introduction of the 5hp screw air compressor represents a significant milestone for (company name) and the industrial machinery sector as a whole. With its advanced technology, energy efficiency, and reliability, this compressor is set to revolutionize the way companies approach air compression. As the industry continues to evolve, it is clear that (company name) remains at the forefront of innovation, delivering solutions that meet the needs of its customers and contribute to the advancement of industrial technology.

Company News & Blog

Everything You Need to Know About Desiccants: Tips and Insights from Experts

Industrial Desiccant Air Dryer: Why It’s Essential to Your BusinessIn any industrial setting, moisture is one of the major impediments to the proper functioning of equipment and machinery. From rust and corrosion to electrical shorts and malfunctions, the effects of moisture can be devastating to your business. However, with industrial desiccant air dryers, you can eliminate these problems and maintain optimal working conditions all year round.What is a Desiccant Air Dryer?A desiccant air dryer is a device that removes moisture from compressed air systems. By drawing air through a desiccant material, it effectively absorbs and traps moisture before releasing dry air back into your system. In this way, desiccant air dryers are able to provide a reliable solution for maintaining the moisture levels of your compressed air systems at acceptable levels, regardless of the environment.Why is It Important to Maintain Proper Moisture Levels?The presence of moisture in compressed air systems can cause a number of problems, including but not limited to:1. Corrosion and RustMoisture in compressed air can cause corrosion and rust in your equipment and machinery, reducing their lifespan and performance.2. Poor Quality of End ProductsMoisture can cause discoloration, deformities, and other abnormalities in your products. This can lead to higher rejection rates, lower-quality end products, and ultimately, lost profits.3. Equipment Failure and DowntimeMoisture can cause shorts, malfunctions, and other failures in equipment and machinery, leading to costly downtime and lost production.4. Increased Maintenance CostsMoisture can cause wear and tear on your equipment, leading to increased maintenance and repairs. This can result in higher costs, longer downtime, and ultimately, lower profits.5. Health and Safety RisksMoisture can also lead to the growth of mold, fungi, and bacteria, creating health and safety hazards for workers in the industrial setting.How Does an Industrial Desiccant Air Dryer Help?An industrial desiccant air dryer helps to mitigate the risks mentioned above by removing moisture from compressed air systems. By maintaining proper moisture levels, you can improve the reliability, efficiency, and safety of your industrial operations. Here are some of the key benefits of using an industrial desiccant air dryer:1. ConsistencyAn industrial desiccant air dryer can provide consistent moisture removal over time, helping to maintain the optimal working conditions of your compressed air system.2. Increased EfficiencyAn industrial desiccant air dryer can help to reduce the workload on other filtration systems, such as oil separators, by removing moisture and other contaminants from compressed air.3. Reduced Maintenance CostsBy removing moisture from your compressed air system, an industrial desiccant air dryer can help to reduce wear and tear on your equipment and machinery, reducing maintenance and repair costs.4. Improved Quality of End ProductsBy maintaining proper moisture levels, an industrial desiccant air dryer can help to reduce discoloration, deformities, and other abnormalities in your products, ensuring high-quality end products.5. Increased SafetyBy reducing the growth of mold, fungi, and bacteria, an industrial desiccant air dryer can help to create a safer working environment for your employees.Choosing the Right Industrial Desiccant Air DryerWhen choosing an industrial desiccant air dryer, there are a few key factors to consider, including the size and type of your compressed air system, the humidity and temperature levels in your environment, and the amount of moisture in your compressed air system.To ensure that you are getting the right industrial desiccant air dryer for your needs, it’s recommended that you consult with a professional in the industry. They can help you determine the best type and size of industrial desiccant air dryer for your business, as well as provide advice on installation and maintenance.ConclusionIn today’s industrial setting, moisture can be a significant problem for equipment, machinery, and end products. However, with the help of an industrial desiccant air dryer, you can reduce the risks associated with moisture and maintain optimal working conditions all year round. By choosing the right industrial desiccant air dryer and implementing proper installation and maintenance, you can ensure the efficiency, reliability, and safety of your industrial operations for years to come.

High-Pressure 2-Stage Rotary Screw Air Compressors Ideal for Harsh Mining Environments

In today's fast-paced world, industries require advanced equipment that can cater to their needs with high precision, speed, and efficiency. One such equipment is the 2-stage rotary screw air compressor GR 110-200, which is designed to provide reliable high-pressure air supply. This compressor is specifically engineered to work in tough conditions, particularly in the mining industry, where it can deliver exceptional performance consistently.The GR 110-200 compressor operates on a 2-stage rotary screw technology, which ensures efficient and reliable performance. It can handle high pressure applications, making it an ideal choice for industries that require a continuous, reliable air supply at high pressure. The compressor has a capacity of up to 20 bar, and it combines power with precision to deliver optimum results.The GR 110-200 compressor is built with advanced features that make it perfect for mining applications. The tough working conditions in mines increase the risk of damage to equipment, but this compressor is designed to withstand these conditions. Its robust construction ensures durability, making it ideal for use in harsh environments. Additionally, the compressor is energy efficient, which reduces energy costs and ensures a lower carbon footprint.Atlas Copco Nigeria is a leading provider of industrial equipment in Nigeria. The company has been in operation for over 80 years and has a vast knowledge of the Nigerian market. It has a range of products tailored to meet the specific needs of its customers, and its equipment is widely used in various industries across the country. The company has a team of experts who provide customers with technical support, maintenance, and repairs services.Atlas Copco Nigeria is committed to customer satisfaction and has a reputation for providing high-quality products and services. The company's focus on innovation has ensured that it remains at the forefront of the industrial equipment market. With a presence in over 180 countries, Atlas Copco has a global network of experts who provide valuable insights into industry trends and developments.In conclusion, the 2-stage rotary screw air compressor GR 110-200 is an ideal choice for industries that require a reliable air supply at high pressure. Its advanced features and robust construction make it suitable for use in tough environments, particularly in mining. Atlas Copco Nigeria's commitment to customer satisfaction ensures that customers receive high-quality products and services. The company's presence in over 180 countries also provides customers with access to valuable insights into industry trends and developments.

High-Quality Air Compressor Dryers for Reliable and Low-Maintenance Performance

Air Compressor Dryers Delivering Unbeatable Reliability and Low MaintenanceThe use of air compressors is an essential component in several industries, including automotive, aerospace, food processing, and construction, among others. Compressed air is a crucial utility that powers various tools, machines, and processes, making production more efficient and effective. However, before the air can be used, it needs to be treated and dried to remove moisture and impurities that can damage the tools and products.To achieve high-quality compressed air, air compressor dryers are used to eliminate the moisture content from the air. Ingersoll Rand is a brand that has been delivering high-quality air compressors and dryers for decades. Their Air Compressor Dryers are known for their reliability, durability, and low maintenance.Ingersoll Rand's Air Compressor Dryers integrate a unique combination of components and features that ensure high-quality compressed air. They use a refrigerated drying system that provides a consistent and reliable dew point for better air quality. The refrigeration system cools the compressed air, causing moisture to condense and collect at the bottom of the dryer, which is then drained out. The cooled air is then reheated to the required temperature, providing dry and clean compressed air.Ingersoll Rand's Air Compressor Dryers are designed to cater to various air compressors and applications. They are available in various sizes and configurations, depending on the user's needs. The dryers can operate in a variety of environments, including high humidity conditions. This makes them ideal for industries that operate in challenging environments, such as chemical processing, food processing, and pharmaceuticals.One of the significant advantages of Ingersoll Rand's Air Compressor Dryers is their low maintenance requirements. These dryers are designed to operate without frequent maintenance, reducing downtime and operational costs. They use environmentally friendly refrigerants, making them an eco-friendly solution to drying compressed air. The dryers are also built with high-quality materials that ensure durability and a long lifespan, even in harsh environments.Ingersoll Rand's Air Compressor Dryers are easy to install and operate. They come with user-friendly controls that are straightforward and easy to understand. The controls are designed to provide optimum performance while requiring minimal intervention from the user. The dryer's automatic controls monitor the system's performance and make adjustments accordingly, ensuring consistent and efficient operation.In conclusion, Ingersoll Rand's Air Compressor Dryers deliver unbeatable reliability and low maintenance requirements. They are designed to provide high-quality compressed air consistently, ensuring efficient and effective production processes. They are available in various configurations and sizes, making them suitable for different applications. Their eco-friendly refrigerants and low maintenance requirements make them a cost-effective solution for drying compressed air. With Ingersoll Rand's Air Compressor Dryers, you can be assured of quality compressed air and worry-free operation.

Powerful 10 HP Screw Compressor for Your Industrial Needs

10 HP Screw Compressor: A Reliable Solution for Your Compressed Air NeedsIn today's industrial and manufacturing landscape, having a reliable source of compressed air is crucial for powering various tools and equipment. This is where the 10 HP Screw Compressor comes in, offering a dependable and efficient solution for businesses looking to meet their compressed air requirements.{Company Name} is proud to introduce the 10 HP Screw Compressor to its line of industrial equipment. With a strong focus on innovation and quality, {Company Name} has been a trusted name in the industry for providing top-notch machinery and tools for various applications.The 10 HP Screw Compressor is designed to deliver consistent and high-quality compressed air, making it an ideal choice for a wide range of industrial and manufacturing operations. Whether it's for powering pneumatic tools, operating machinery, or even for use in HVAC systems, this compressor is up to the task.One of the key features of the 10 HP Screw Compressor is its energy efficiency. With a focus on reducing energy consumption and operating costs, this compressor is designed to deliver maximum performance while minimizing power requirements. This not only helps businesses save on energy bills but also contributes to a more sustainable and eco-friendly operation.Another standout feature of the 10 HP Screw Compressor is its durability and reliability. Built to withstand the rigors of industrial use, this compressor is constructed using high-quality materials and components, ensuring long-term performance and minimal downtime. This reliability is crucial for businesses that rely on compressed air for their day-to-day operations.Maintenance is also made easy with the 10 HP Screw Compressor, thanks to its user-friendly design and accessible components. This allows for quick and hassle-free servicing, keeping downtime to a minimum and ensuring that the compressor operates at peak efficiency.In addition, {Company Name} offers comprehensive support and service for the 10 HP Screw Compressor, including installation, training, and ongoing maintenance. This ensures that businesses can maximize the performance and lifespan of their compressor, allowing them to focus on their core operations with confidence.The 10 HP Screw Compressor is available in various configurations to suit different application needs, making it a versatile and adaptable solution for businesses of all sizes and industries. Whether it's for a small workshop or a large-scale manufacturing facility, this compressor can be tailored to meet specific compressed air requirements.With a commitment to quality, performance, and customer satisfaction, {Company Name} stands behind the 10 HP Screw Compressor, offering a reliable and cost-effective solution for businesses looking to optimize their compressed air systems.In conclusion, the 10 HP Screw Compressor from {Company Name} is a standout solution for businesses in need of a reliable and efficient source of compressed air. With its energy-efficient design, durability, and comprehensive support, this compressor is a valuable addition to any industrial operation, helping businesses meet their compressed air needs with confidence and peace of mind.

Powerful Screw Air Compressor With 30 Horsepower

Catering to the growing need for efficient air compressors, a leading manufacturer in the industry has introduced a 30 Hp Screw Air Compressor. The company, which has been in the business for decades, has built a reputation for producing high-quality compressors that are widely used in various industrial settings.The 30 Hp Screw Air Compressor is designed to provide superior performance, reliability, and efficiency. With a powerful motor and advanced technology, this compressor can efficiently provide compressed air for various applications, including powering pneumatic tools and machines, supplying clean air for spray painting, and many more.The compressor is built to withstand the toughest working conditions, and its sturdy construction ensures durability and longevity. The advanced control panel allows users to adjust the air output and pressure, ensuring maximum efficiency and energy savings. Additionally, the compressor is equipped with a state-of-the-art cooling system that prevents overheating and improves the overall performance.The company spokesperson commented, "We are proud to introduce our new 30 Hp Screw Air Compressor, which is the latest addition to our product line. The compressor has been designed and developed with the latest technology and superior quality standards to meet the ever-increasing demands of our customers. We take pride in our ability to deliver reliable and efficient compressors that are essential for various industrial applications."The company has been at the forefront of industrial compressor manufacturing, supplying compressors to various industries, including automotive, textile, food processing, and many more. The company maintains a strict quality control process, ensuring that their products meet the highest industry standards."Our commitment to quality and customer satisfaction is reflected in every product we manufacture. We have a team of highly skilled professionals who work tirelessly to deliver the best products to our customers. Our new 30 Hp Screw Air Compressor is just another example of our dedication to excellence," concluded the spokesperson.In conclusion, the introduction of the 30 Hp Screw Air Compressor highlights the company's commitment to innovation and providing reliable and efficient industrial compressors. With advanced technology and superior quality standards, this compressor is set to become a popular choice in various industries. The company's dedication to customer satisfaction and quality is sure to make this compressor a success in the market.

Distributor of High-Quality Screw Air Compressors" becomes "Top-Quality Screw Air Compressor Distributor

[Insert Company Name] Becomes the Leading Distributor of Efficient Screw Air Compressors [City, Date] – [Insert Company Name], a well-established distributor of industrial equipment, is proud to announce its partnership with an innovative manufacturer, allowing them to become the leading distributor of efficient screw air compressors in the market. With their commitment to providing the highest quality products and excellent customer service, [Insert Company Name] is set to revolutionize the industry and meet the growing demands of various sectors.[Insert Company Name] has built a strong reputation over the years as a reliable supplier of industrial equipment. With a vast product portfolio and a dedicated team of experts, they have served numerous clients across different industries, including manufacturing, construction, and automotive. Their commitment to providing best-in-class solutions has enabled them to establish long-term relationships and maintain a loyal customer base.The partnership with [Manufacturer Name] has further strengthened [Insert Company Name]'s position in the market. As a renowned manufacturer, [Manufacturer Name] has set new standards for efficiency, reliability, and durability in the field of screw air compressors. By collaborating with such an esteemed partner, [Insert Company Name] ensures that their customers will benefit from the latest technological advancements and industry-leading products.One of the key advantages of [Manufacturer Name]'s screw air compressors is their energy efficiency. With rising concerns about environmental sustainability and soaring energy costs, companies are increasingly looking for equipment that minimizes energy consumption. The screw air compressors offered by [Insert Company Name] are designed with cutting-edge technology that utilizes energy-efficient motors and components, resulting in reduced power consumption and lower carbon footprint.Another notable feature of these screw air compressors is their exceptional performance. Equipped with advanced control systems and precision engineering, these compressors deliver consistent, reliable, and high-pressure airflow. Whether it is for powering pneumatic tools, operating machinery, or running entire production lines, these compressors will meet the demands of even the most rigorous applications.Durability is a fundamental consideration for any industrial equipment, and [Manufacturer Name]'s screw air compressors excel in this aspect. Built with rugged materials, advanced cooling systems, and an emphasis on preventative maintenance, these compressors can operate seamlessly under challenging conditions. [Insert Company Name] ensures comprehensive after-sales support, including regular maintenance, spare parts availability, and technical assistance, further enhancing the longevity and reliability of these compressors.[Insert Company Name] also understands that each customer's requirements are unique. To meet these diverse needs, they provide a range of screw air compressors with varying specifications, sizes, and configurations. Their team of experts works closely with customers to understand their applications and recommend the most suitable compressor that maximizes efficiency and productivity while minimizing costs.In addition to the exceptional products, [Insert Company Name] is renowned for delivering exceptional customer service. Their trained sales representatives assist customers from initial inquiries through to after-sales support, ensuring a smooth and hassle-free experience. The company prides itself on building long-term partnerships with customers, providing ongoing assistance, and adapting to their evolving needs.With their newly acquired position as the leading distributor of efficient screw air compressors, [Insert Company Name] will continue to contribute to the growth and success of various industries. By offering advanced technology, energy efficiency, exceptional performance, and outstanding customer service, they aim to exceed customer expectations and maintain their status as a trusted supplier of industrial equipment.About [Insert Company Name]:[Insert Company Name] is a leading distributor of industrial equipment, serving various industries such as manufacturing, construction, and automotive. With a diverse product range, commitment to excellence, and exceptional customer service, they have established themselves as a partner of choice for businesses across the region. Their collaboration with reputed manufacturers allows them to deliver cutting-edge solutions that enhance efficiency, productivity, and sustainability.Press Contact:[Insert Contact Name][Insert Company Name][Insert Contact Email][Insert Contact Phone Number]

Enhancing Efficiency: Unveiling the Power of Single Stage Screw Compressors

Single Stage Screw Compressor Revolutionizing Industrial Air CompressionIn today's fast-paced industrial landscape, efficiency and productivity are of paramount importance. Companies across various sectors are constantly searching for innovative solutions that can streamline their processes and maximize output. One such revolutionary solution is the Single Stage Screw Compressor, a cutting-edge technology that is transforming the field of air compression.With its advanced design and unparalleled performance, the Single Stage Screw Compressor, developed by a leading global engineering company, is catering to the diverse needs of industrial applications. This compressor has gained significant popularity in recent years, particularly due to its ability to deliver high-quality compressed air efficiently and cost-effectively.The Single Stage Screw Compressor is designed to optimize energy consumption, thereby reducing operating costs and increasing overall efficiency. By eliminating the need for multi-stage compression, this compressor can significantly reduce energy waste and lower maintenance expenses. Moreover, its compact size and user-friendly interface enable easy installation and operation, making it a preferred choice for various industries.One of the key features of this compressor is its superior reliability and durability. The powerful screw mechanism used in the compressor ensures smooth and consistent air compression, minimizing the risk of breakdowns and interruptions in production. This reliability factor has been a game-changer for industries that rely heavily on compressed air, such as manufacturing, automotive, and pharmaceutical sectors.Furthermore, the Single Stage Screw Compressor boasts advanced control systems and smart technologies that enhance its performance and productivity. Equipped with intuitive monitoring and diagnostic features, operators can easily track and adjust the compressor's settings in real-time, ensuring optimal performance and preventing potential issues. This proactive approach to maintenance helps minimize downtime and ensures steady production flow.Another remarkable aspect of this compressor lies in its environmental friendliness. Committed to sustainability, the manufacturer has implemented various energy-efficient components and technologies in its design. Through advanced heat recovery systems and optimized cooling mechanisms, this compressor not only reduces energy consumption but also lowers greenhouse gas emissions. This eco-friendly approach has been well-received by companies looking to align their operations with environmental regulations and reduce their carbon footprint.The Single Stage Screw Compressor's versatility in terms of air capacity and pressure requirements further solidifies its reputation in the market. Available in a wide range of sizes, it can cater to a spectrum of industrial needs, from small-scale workshops to large-scale manufacturing plants. Its flexibility in pressure control allows for precise adjustments, ensuring compatibility with various equipment and production processes.The compressor manufacturer, with years of experience in the field, has gained a global reputation for its commitment to quality, reliability, and customer satisfaction. The company prides itself on offering comprehensive after-sales services, including installation, routine maintenance, and emergency support, ensuring uninterrupted operation for its clients. Moreover, its global network of service centers and trained technicians ensures prompt assistance wherever needed.As the demand for compressed air continues to rise, industries are seeking innovative solutions that can provide optimal performance, efficiency, and reliability. The Single Stage Screw Compressor, with this unique combination, has emerged as a game-changer in the field of air compression. Its ability to revolutionize industrial processes, while minimizing operational costs and environmental impact, has positioned it as a leading choice for companies across a myriad of sectors.In conclusion, the Single Stage Screw Compressor is transforming the industrial air compression landscape with its revolutionary design, advanced technologies, and unmatched performance. Its energy efficiency, reliability, and versatility make it an ideal choice for industries looking to maximize productivity and reduce operational costs. With its commitment to customer satisfaction and sustainability, the manufacturer has firmly established itself as a leader in the field. As businesses strive for continuous improvement, the Single Stage Screw Compressor remains at the forefront of innovation, paving the way for a more efficient and sustainable future.

Discover the Advantages of Industrial Oil Free Air Compressors for Efficient Operations

[Industrial Oil-Free Air Compressor] Revolutionizing the Manufacturing Industry[City, Date] - In today's manufacturing sector, efficiency, sustainability, and cleanliness are of paramount importance. With the increasing awareness of environmental concerns and the need for reducing carbon footprints, industries are embracing innovative technologies to enhance their productivity while minimizing their impact on the environment. One such groundbreaking solution that has caught the attention of manufacturers worldwide is the Industrial Oil-Free Air Compressor, designed and developed by a leading industry player.A pioneer in air compressor technology, this company has revolutionized the manufacturing industry with its state-of-the-art oil-free air compressor. Combining advanced engineering techniques with extensive research and development, they have created a compressor that offers numerous benefits to manufacturing facilities, making it an indispensable asset within industrial settings.The Industrial Oil-Free Air Compressor serves as an energy-efficient alternative to traditional oil-lubricated compressors. By eliminating the need for oil, it delivers compressed air that is entirely free from any oil contaminants. This ensures that the air meets the highest standards of purity, making it particularly suitable for industries that demand clean air, such as pharmaceuticals, food and beverages, electronics, and automotive manufacturing.Featuring cutting-edge technology, this air compressor guarantees exceptional performance, reduced maintenance costs, and minimized downtime. The advanced design utilizes a series of precision-engineered components to achieve remarkable efficiency, resulting in significant energy savings for the company. By avoiding the use of oil, manufacturers can eliminate the associated costs of oil procurement, disposal, and maintenance, leading to substantial financial savings.Moreover, the Industrial Oil-Free Air Compressor exceeds regulatory standards set by environmental agencies worldwide. With a focus on sustainability, the company has created a compressor that significantly reduces carbon emissions, contributing to a cleaner and greener environment. By eliminating oil, which is a major source of air pollution, the compressor has achieved an impressive environmental footprint. This makes it an excellent choice for companies aiming to fulfill their corporate social responsibility by adopting eco-friendly practices.The oil-free design also ensures that the compressor operates quietly, without compromising on performance. This feature is particularly valuable for manufacturing units located in urban areas or those situated in close proximity to residential areas. The reduced noise levels promote a healthier, more comfortable working environment for employees while enhancing the overall harmony within the community.In addition to these advantages, the Industrial Oil-Free Air Compressor offers unmatched reliability and durability. With rigorous quality control and meticulous testing procedures, the company guarantees that each compressor leaving their factory is of the highest standard. This reliability ensures minimal disruptions to the manufacturing process, safeguarding productivity and reducing costly downtime.With an unwavering commitment to customer satisfaction, the company not only provides cutting-edge technology but also offers exceptional customer service. A team of highly skilled engineers and technicians provides prompt assistance, ensuring that each client receives personalized support tailored to their unique requirements.As the industrial landscape continues to evolve, manufacturers must adapt to emerging trends and technologies to stay ahead in the competitive market. The Industrial Oil-Free Air Compressor represents the future of compressed air solutions, providing manufacturers with the means to improve productivity, reduce costs, and align with sustainable practices. With an emphasis on quality, efficiency, and environmental consciousness, this compressor is poised to transform the manufacturing industry, offering businesses a reliable and dynamic solution for their compressed air needs.About [Company]:[Company] is a pioneering force in the air compressor industry, specializing in innovative and sustainable compressed air solutions. With a global presence and a commitment to excellence, [Company] has established itself as a trusted provider of state-of-the-art compressors, catering to a diverse range of industries. By combining cutting-edge technology, extensive research, and unparalleled customer service, [Company] continues to shape the future of compressed air solutions worldwide.For media inquiries, please contact:[Contact Information]###

Comparing Different Types of Rotary Air Compressors for Efficient Industrial Applications

Title: Rotary Air Compressor Types: A Comprehensive OverviewIntroduction:Rotary air compressors have become indispensable in various industries due to their efficiency and reliability. These devices are capable of delivering a continuous supply of compressed air by utilizing rotary motion. In this article, we will provide a comprehensive overview of the different types of rotary air compressors and their applications. 1. Rotary Screw Air Compressors:Rotary screw air compressors are one of the most commonly used types in the industry. They operate through the interaction of two helical rotors (male and female) inside a chamber. As the rotors rotate, the air is trapped and gradually compressed. These compressors are known for their high energy efficiency, low maintenance requirements, and quiet operation. They are extensively used in automotive, manufacturing, and construction industries.2. Rotary Vane Air Compressors:Rotary vane air compressors employ vanes fitted into a rotor housed in a cylindrical casing. As the rotor spins, the vanes slide in and out, creating compression and generating compressed air. These compressors are compact, lightweight, and offer a continuous flow of air. They find applications in dental clinics, laboratories, painting, and pneumatic tools.3. Variable Speed Drive (VSD) Rotary Compressors:VSD rotary compressors are equipped with an integrated variable speed drive system, allowing the compressor to adjust its speed and match the demand for compressed air accurately. By varying the rotational speed, these compressors optimize energy consumption and reduce operating costs significantly. They are ideal for applications where compressed air demand fluctuates frequently.4. Oil-Flooded Rotary Compressors:Oil-flooded rotary compressors utilize oil as a lubricant and coolant. The compression process occurs between two rotors, and the oil injected aids cooling, sealing, and lubrication. These compressors generate high-quality compressed air while minimizing wear and tear, making them suitable for sensitive applications such as electronics manufacturing and food processing.5. Oil-Free Rotary Compressors:Oil-free rotary compressors, as the name suggests, do not require oil for their operation. They ensure clean and oil-free compressed air, making them suitable for applications where oil contamination is a concern, such as pharmaceuticals, food and beverage, and electronics. Furthermore, these compressors reduce maintenance costs as they eliminate the need for oil changes and filter replacements.6. Portable Rotary Screw Compressors:Portable rotary screw compressors are compact, mobile, and offer convenience for various industries that require compressed air on the move. These compressors can be easily mounted on service vehicles and are commonly used in construction sites, roadworks, and emergency repair services.In conclusion, rotary air compressors come in several types, each with its own distinct advantages and applications. Whether it is screw, vane, variable speed drive, oil-flooded, oil-free, or portable rotary compressors, these devices play a crucial role in powering various industrial operations. Understanding the different types can help industries choose the most suitable compressor for their specific needs, ensuring optimal performance, energy efficiency, and durability.

Reliable and Durable Industrial Air Compressors for Various Applications

Industrial Air Compressors: The Key to Success in Manufacturing and ProcessingIndustrial processes rely heavily on machines and equipment to accomplish tasks with precision and speed. Often, these machines require a reliable source of compressed air to operate efficiently. That is why industrial air compressors have become an essential component in manufacturing and processing plants.The market offers a broad range of industrial air compressors designed for specific tasks, making it important to choose the right one for the job. Ingersoll Rand (the brand name is intended to be removed in this article) is one of the leading manufacturers of industrial air compressors worldwide. The company has an established reputation for providing durable, reliable, and effective products.Ingersoll Rand's industrial air compressors cater to a variety of industrial applications, from automotive, aerospace, and electronics to food and beverage, pharmaceuticals, and mining. In this article, we will discuss the benefits of using industrial air compressors and how they can help businesses thrive.What are industrial air compressors?An industrial air compressor is a machine that converts electrical energy into compressed air. The compressed air is stored in a tank or receiver and distributed through a network of pipes to power various tools and machines. Industrial air compressors can come equipped with different technologies, including rotary screw, piston, and centrifugal compressors.Advantages of industrial air compressorsIndustrial air compressors offer numerous advantages to businesses that rely on them for various applications. Here are some of the key benefits:1. Increased efficiencyIndustrial air compressors provide a consistent and reliable source of compressed air, which improves the efficiency and output of machines and equipment. The compressed air helps minimize downtime, increases productivity, and reduces energy costs.2. VersatilityIndustrial air compressors are versatile machines that can power a wide range of tools and machines. They are used in many applications, including pneumatic tools, spray painting, sandblasting, plasma cutting, and more.3. DurabilityIndustrial air compressors are built to withstand harsh industrial environments and heavy usage. They are designed with rugged components that can withstand wear and tear, ensuring long-term durability and reliability.4. Improved air qualityIndustrial air compressors can purify compressed air, making it suitable for use in clean environments such as medical facilities, food processing plants, and laboratories. The compressed air can be filtered, dried, and purified to remove contaminants and moisture, ensuring a clean and safe environment.Ingersoll Rand's Industrial Air CompressorsIngersoll Rand offers a broad range of industrial air compressors that cater to different industrial applications. Here are some of the popular models:1. Two-stage electric-driven stationary air compressorsThese models are designed for heavy-duty applications such as automotive, fabrication, and metalworking. They come with a high-efficiency motor, cast iron pump, and finned copper intercooler for maximum performance and durability.2. Single-stage electric-driven stationary air compressorsThese compressors are designed for small to medium-sized businesses that require reliable and efficient compressed air. They are compact, easy to install, and come equipped with a cast iron pump for durability.3. High-pressure rotary screw air compressorsThese compressors are designed for applications that require high-pressure compressed air, such as gas and oil processing, mining, and petrochemicals. They come with advanced control systems that optimize performance and reduce energy costs.4. Centrifugal air compressorsThese compressors are designed for high-volume applications such as air separation, power generation, and oil and gas refining. They offer high efficiency, reliability, and reduced maintenance costs.In conclusion, industrial air compressors play a crucial role in many manufacturing and processing plants, powering various tools and machines. Ingersoll Rand's range of industrial air compressors offers reliable, durable, and efficient performance, ensuring businesses can succeed in today's competitive market.