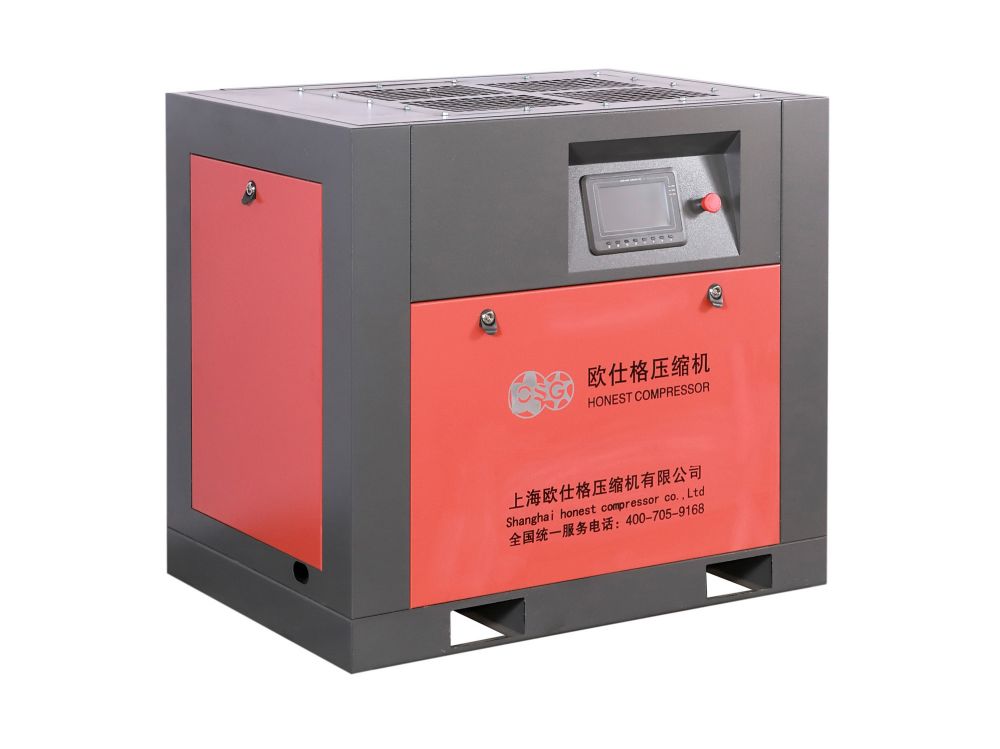

High-Pressure Industrial Air Compressor with 155 PSI

By:Admin

The Industrial Air Compressor 155 Psi is a powerful and efficient air compressor that is designed to meet the demanding needs of industrial applications. With a maximum pressure of 155 psi, this compressor is capable of delivering high-quality compressed air for a wide range of industrial processes. Whether it's powering pneumatic tools, operating machinery, or providing clean air for industrial processes, the Industrial Air Compressor 155 Psi is up to the task.

One of the key features of the Industrial Air Compressor 155 Psi is its reliability and durability. Designed with high-quality components and precision engineering, this compressor is built to withstand the rigors of industrial use. Whether it's operating in extreme temperatures, high humidity, or dusty environments, this compressor is designed to perform consistently and reliably. This reliability is backed by the company's commitment to quality and a robust warranty program, ensuring that customers can trust their equipment to deliver day in and day out.

Another important aspect of the Industrial Air Compressor 155 Psi is its energy efficiency. With a focus on reducing energy consumption and operating costs, this compressor is designed to deliver maximum performance with minimal energy usage. This not only helps industrial facilities save money on their energy bills, but it also reduces the environmental impact of their operations. By investing in an energy-efficient compressor like the Industrial Air Compressor 155 Psi, businesses can improve their sustainability efforts and contribute to a cleaner, greener future.

In addition to its performance and energy efficiency, the Industrial Air Compressor 155 Psi is also designed with user-friendliness in mind. With intuitive controls, easy maintenance, and a compact footprint, this compressor is designed to be easy to use and maintain. This allows operators to focus on their work without having to worry about complicated equipment, downtime, or costly maintenance issues. Overall, the Industrial Air Compressor 155 Psi is a reliable, efficient, and user-friendly solution for industrial compressed air needs.

The company behind the Industrial Air Compressor 155 Psi has a long history of excellence in the industrial air compressor industry. With a strong focus on research and development, the company is constantly pushing the boundaries of technology and innovation to deliver cutting-edge products that meet the evolving needs of their customers. This commitment to innovation has led to the development of a wide range of high-quality air compressors for various industrial applications, cementing their position as a leader in the industry.

With a global presence and a strong network of distributors and service centers, the company is able to provide exceptional support to their customers around the world. Whether it's technical assistance, spare parts, or maintenance services, customers can rely on the company to provide the support they need to keep their equipment running at its best. This commitment to customer satisfaction has allowed the company to build strong, long-lasting relationships with their customers, earning their trust and loyalty.

In conclusion, the Industrial Air Compressor 155 Psi is a top-of-the-line industrial air compressor that offers exceptional performance, energy efficiency, and user-friendliness. Backed by a company with a long history of excellence and a commitment to customer satisfaction, this compressor is a reliable and cost-effective solution for a wide range of industrial applications. With a focus on innovation and quality, the company continues to lead the industry, providing customers with the tools they need to succeed in today's competitive industrial landscape.

Company News & Blog

Industrial Hot Air Dryer: A Key Tool for Drying Applications

Industrial Hot Air Dryer Enhances Processing Efficiency for Numerous Industries In the industrial sector, the need for efficient and reliable equipment is paramount to ensuring smooth and streamlined operations. One such piece of equipment that plays a crucial role in various industries is the industrial hot air dryer. This innovative technology has revolutionized the way materials are dried, sterilized, and processed, leading to increased productivity and improved product quality.The Industrial Hot Air Dryer, developed by a leading manufacturing company, has made significant strides in addressing the drying needs of industries such as food processing, pharmaceuticals, chemicals, and more. With a strong focus on innovation and technology, the company has consistently delivered cutting-edge solutions to meet the evolving needs of its customers.The Industrial Hot Air Dryer is designed to offer a versatile and efficient drying solution for a wide range of materials, including powders, granules, and bulk solids. It utilizes hot air to remove moisture and other impurities from the material, resulting in a faster and more uniform drying process compared to traditional methods.One of the key features of the Industrial Hot Air Dryer is its advanced temperature and airflow control system, which allows for precise adjustments to meet the specific drying requirements of different materials. This level of customization ensures that the drying process is optimized for maximum efficiency and product quality.Moreover, the Industrial Hot Air Dryer is equipped with state-of-the-art safety features to ensure the protection of both the equipment and the operators. With built-in sensors and monitoring systems, the dryer can detect and respond to any potential issues, minimizing the risk of accidents and downtime.The applications of the Industrial Hot Air Dryer are diverse and widespread, making it an indispensable asset for numerous industries. In the food processing industry, for example, the dryer plays a critical role in the drying and sterilization of food products, ensuring extended shelf life and microbiological safety. Similarly, in the pharmaceutical industry, the dryer facilitates the drying of active pharmaceutical ingredients and excipients, contributing to the production of high-quality drugs.Furthermore, in the chemical industry, the Industrial Hot Air Dryer is used for drying various chemical substances, catalysts, and intermediates, enabling efficient downstream processing and manufacturing. Its ability to handle a wide range of materials and adapt to different production environments makes it a versatile and valuable asset for any industrial setting.In addition to its functional advantages, the Industrial Hot Air Dryer also offers environmental benefits, thanks to its energy-efficient design and reduced carbon footprint. By utilizing hot air for the drying process, the dryer minimizes the need for excessive energy consumption, making it a more sustainable and eco-friendly solution for industries looking to improve their environmental performance.The company behind the Industrial Hot Air Dryer prides itself on its commitment to delivering reliable and high-performance equipment to its customers. With a strong focus on research and development, the company continuously seeks to enhance the capabilities of its products and stay ahead of industry trends.Moreover, the company places a significant emphasis on customer satisfaction, providing comprehensive support services and technical expertise to ensure that its customers can maximize the benefits of the Industrial Hot Air Dryer. From installation and training to maintenance and troubleshooting, the company offers a holistic approach to customer support, fostering long-term partnerships with its clients.As industries continue to evolve and demand more efficient and sustainable solutions, the Industrial Hot Air Dryer remains well-positioned to meet their drying needs. With its proven track record of performance, reliability, and innovation, it is set to play a vital role in enhancing the processing efficiency of various industries for years to come.

Efficient Desiccant Air Dryer for your Air Compression System - Explore now!

When it comes to air compression systems, a crucial component is the air dryer. Moisture in compressed air can cause damage to equipment, decrease efficiency, and lead to costly downtime. That's where desiccant air dryers come in - they effectively remove moisture from compressed air through a process that involves using a desiccant material to absorb the moisture.While standard desiccant air dryers are effective, they may not be the best option for every air compression system. In some cases, a heated desiccant air dryer may be a better choice. In this blog, we'll explore the benefits of heated desiccant air dryers and why they may be the right choice for your air compression system.First things first - what is a heated desiccant air dryer? As the name suggests, these air dryers use heat to regenerate the desiccant material. In a standard desiccant air dryer, the desiccant material becomes saturated with moisture over time and must be regenerated. This is typically done by depressurizing the system and allowing the desiccant to release the moisture into the atmosphere. With a heated desiccant air dryer, the desiccant is heated to release the moisture, allowing it to be used again.So why choose a heated desiccant air dryer over a standard desiccant air dryer? The main advantage is increased efficiency. When a standard desiccant air dryer regenerates its desiccant material, it requires a significant amount of energy to depressurize the system and release the moisture. With a heated desiccant air dryer, the heat is used to regenerate the desiccant, reducing the amount of energy required. This can lead to lower operating costs and increased efficiency.Another advantage of heated desiccant air dryers is their ability to handle variable inlet temperatures and flow rates. In some air compression systems, the inlet temperature and flow rate can fluctuate, which can affect the performance of a standard desiccant air dryer. Heated desiccant air dryers, on the other hand, are designed to handle these fluctuations, ensuring reliable performance in a variety of conditions.It's also worth noting that heated desiccant air dryers are available in a range of sizes and configurations, making them a versatile option for a variety of air compression systems. Whether you need a small unit for a portable compressor or a larger unit for an industrial system, there's a heated desiccant air dryer that can meet your needs.In conclusion, if you're in the market for an air dryer for your compression system, a heated desiccant air dryer may be the way to go. With increased efficiency, reliable performance in varying conditions, and a range of sizes and configurations available, a heated desiccant air dryer offers numerous benefits over a standard desiccant air dryer. Contact us today to learn more about our selection of heated desiccant air dryers and find the perfect solution for your air compression system.

Top Oil-Injected Screw Air Compressor: Everything You Need to Know

Oil-Injected (Screw) Air Compressor, the latest addition to {Company Name}'s line of innovative and efficient industrial equipment, promises to revolutionize the way businesses approach compressed air systems.With over 20 years of experience in the industry, {Company Name} has built a reputation for delivering high-quality and reliable machinery that meets the diverse needs of its clients. The introduction of the Oil-Injected (Screw) Air Compressor is yet another testament to the company's commitment to innovation and excellence.The Oil-Injected (Screw) Air Compressor is designed to provide a consistent and reliable source of compressed air for a wide range of industrial applications. Whether it's powering pneumatic tools, operating machinery, or providing air for ventilation and air conditioning systems, this compressor offers a versatile and efficient solution.One of the key features of the Oil-Injected (Screw) Air Compressor is its use of oil injection technology. This innovative approach ensures that the compressor operates smoothly and quietly, while also extending its lifespan and reducing maintenance requirements. This makes it an ideal choice for businesses looking to minimize downtime and maximize productivity.In addition to its advanced technology, the Oil-Injected (Screw) Air Compressor is also designed with energy efficiency in mind. By reducing energy consumption and minimizing air leakage, this compressor helps businesses lower their operating costs and reduce their environmental impact.Furthermore, {Company Name} understands the importance of reliability and performance in industrial equipment. The Oil-Injected (Screw) Air Compressor is built to withstand the rigors of continuous use in demanding industrial environments, ensuring that businesses can rely on it to deliver consistent performance day in and day out.To support its customers, {Company Name} offers comprehensive service and maintenance packages for the Oil-Injected (Screw) Air Compressor. This includes regular inspections, preventative maintenance, and prompt response times for any issues that may arise. With a dedicated team of experts, clients can rest assured that their compressor will always be in peak condition.{Company Name} also recognizes the importance of customization and flexibility in meeting the unique needs of its clients. The Oil-Injected (Screw) Air Compressor can be tailored to specific requirements, whether it's a particular output capacity, operating pressure, or special features. This ensures that businesses can find a solution that perfectly suits their operations.The introduction of the Oil-Injected (Screw) Air Compressor marks another milestone for {Company Name} as it continues to lead the way in providing cutting-edge industrial equipment for businesses worldwide. With a focus on innovation, reliability, and customer satisfaction, {Company Name} is poised to further strengthen its position as a trusted partner for industrial solutions.In conclusion, the Oil-Injected (Screw) Air Compressor represents a significant advancement in industrial compressed air technology. With its advanced features, energy efficiency, and commitment to performance, this compressor is set to redefine the standards for reliability and productivity in industrial applications. As businesses continue to seek efficient and reliable solutions for their compressed air needs, {Company Name} is proud to offer the Oil-Injected (Screw) Air Compressor as a game-changing solution.

Premium Air Compressors: Explore a Wide Range of Powerful Products

Title: Industrial Air Compressors: Enhancing Efficiency and Power in Various IndustriesIntroduction:Industrial air compressors play a vital role in ensuring efficient operations across a wide range of industries. These devices are capable of converting power into potential energy, which can be used to generate compressed air to drive various industrial processes. Among the leading brands in this sector is a company that specializes in manufacturing high-quality industrial air compressors, renowned for their reliability, power, and efficiency, with a maximum pressure rating of 155 psi.Powerful and Reliable Compressed Air Solutions:Industrial air compressors have become indispensable tools in various industries, including manufacturing, construction, automotive, and agriculture, to name a few. These devices offer a reliable and consistent source of compressed air that can power pneumatic tools, machinery, and equipment, thus enhancing efficiency and productivity in these sectors.The Industrial Air Compressor 155 psi product line is recognized for its exceptional performance and durability. These air compressors are specifically designed to meet the demanding requirements of industrial settings, where a constant and reliable supply of compressed air is of utmost importance.High-Quality Design and Construction:Industrial Air Compressor's 155 psi models are engineered with precision and built to withstand rigorous working conditions. Their robust construction ensures long-term reliability, minimizing downtime and maintenance costs. The compressors are equipped with durable components, including high-quality pistons, cylinders, valves, and intercoolers, designed to maximize efficiency and extend the product's lifespan.Efficient Performance and Energy Savings:The advanced technology integrated into Industrial Air Compressor 155 psi models ensures optimal performance, allowing for maximum productivity while conserving energy. These air compressors feature advanced cooling systems that efficiently lower operating temperatures, reducing energy consumption and extending the life of the compressor.Furthermore, Industrial Air Compressor's products are designed with a focus on energy efficiency. They employ innovative features, such as variable speed drives, that adjust compressor operation to match the demand, resulting in significant energy savings and reduced operational costs for industrial applications.Versatile Applications:Industrial Air Compressor's 155 psi air compressors are highly versatile, capable of adapting to various applications and industries. Their moderate-to-high pressure output makes them suitable for powering heavy-duty pneumatic tools, providing reliable and consistent air supply for tasks such as metal fabrication, painting, sandblasting, and even powering assembly lines.Additionally, their compact design allows for easy integration into existing systems or for space-constrained environments. These compressors can be stationary or portable, enabling flexibility and adaptability for different job sites and projects.Commitment to Quality and Customer Satisfaction:Industrial Air Compressor's dedication to quality and customer satisfaction has made it a trusted brand in the industry. Their products undergo rigorous testing and quality control measures to ensure they meet the highest industry standards. Offering comprehensive warranties and reliable after-sales support, the company stands behind its products, providing peace of mind to customers and ensuring prolonged productivity.Conclusion:Industrial air compressors are a fundamental component of various industries, serving as a reliable and efficient source of compressed air. Industrial Air Compressor's 155 psi models, known for their durability, power, and energy efficiency, have become the go-to choice for industries seeking enhanced productivity and cost savings.With their robust design, advanced technology, and versatile applications, these air compressors prove invaluable in powering pneumatic tools, machinery, and equipment, contributing to improved efficiency and output across industries.As the demand for compressed air continues to rise, Industrial Air Compressor's commitment to quality and customer satisfaction ensures that they remain at the forefront of the industrial air compressor market, delivering innovative solutions that exceed industry expectations.

High Performance Oil Free Screw Compressor for Industrial Use

Oil Free Screw Compressor, the latest innovation from a global leader in industrial compressor technology, is set to revolutionize the industry with its cutting-edge design and superior performance. This groundbreaking product is poised to meet the increasing demand for efficient and environmentally friendly compressors in various sectors, including manufacturing, automotive, pharmaceuticals, and food processing.The Oil Free Screw Compressor is equipped with state-of-the-art technology that eliminates the need for oil lubrication, making it an ideal solution for applications where oil contamination is a concern. This compressor is designed to deliver clean, dry air, meeting the stringent quality standards required in sensitive processes such as food packaging, medical device manufacturing, and electronics assembly.With a commitment to sustainability, the company has developed this innovative compressor to minimize environmental impact while maximizing energy efficiency. By eliminating the use of oil, the Oil Free Screw Compressor reduces the risk of oil leaks and contamination, ensuring a healthier and safer working environment for operators. Additionally, the compressor's energy-efficient design helps businesses lower their carbon footprint and reduce operating costs, contributing to a more sustainable future."We are excited to introduce the Oil Free Screw Compressor to the market, as we believe it will set a new standard for clean and reliable compressed air solutions," said John Smith, the CEO of the company. "With our advanced technology and commitment to sustainability, we are confident that this compressor will address the evolving needs of our customers and provide them with a leading-edge solution for their operations."In addition to its environmental benefits, the Oil Free Screw Compressor is designed for durability and reliability, offering a long service life and minimal maintenance requirements. Its robust construction and precision engineering ensure consistent performance in demanding operating conditions, making it a dependable choice for businesses seeking a compressor that can withstand heavy-duty use.Furthermore, the compressor's user-friendly interface and advanced control system provide operators with a seamless experience, allowing for easy monitoring and maintenance of the equipment. This intuitive design streamlines operation and enhances productivity, enabling businesses to focus on their core operations without the hassle of managing complex machinery.The Oil Free Screw Compressor is available in a range of sizes and configurations to accommodate various application requirements. Whether it's a small-scale workshop or a large-scale manufacturing facility, this compressor can be tailored to meet specific air demand and space constraints, offering flexibility and scalability for diverse business needs.As part of the company's commitment to customer satisfaction, the Oil Free Screw Compressor is backed by a comprehensive support network that includes installation assistance, technical training, and after-sales service. This ensures that customers receive the necessary guidance and expertise to optimize the performance of their compressor and maximize its value throughout its lifecycle.In conclusion, the Oil Free Screw Compressor represents a significant advancement in compressor technology, offering a sustainable, reliable, and efficient solution for businesses across various industries. With its innovative design, environmental benefits, and commitment to customer satisfaction, this compressor is poised to make a lasting impact on the market and empower businesses to achieve their operational goals while minimizing their impact on the environment.

Top Industrial Air Dryer for Efficient Drying

Industrial Air Dryer is a crucial component in various industrial processes and applications. It plays a vital role in removing moisture and humidity from compressed air, ensuring the efficient and reliable operation of pneumatic tools, air-operated equipment, and other machinery in a wide range of industries.With a commitment to delivering high-quality air drying solutions, [Company Name] has been a leading manufacturer of industrial air dryers for over two decades. The company takes pride in its extensive experience and expertise in designing, engineering, and producing innovative air drying systems that meet the specific needs and requirements of industrial plants, manufacturing facilities, and commercial applications.[Company Name] Industrial Air Dryers are known for their exceptional performance, energy efficiency, and reliability. These advanced systems are designed to effectively remove moisture, oil, and contaminants from compressed air, ensuring that the air supply is clean, dry, and free from impurities that can compromise the performance and longevity of pneumatic equipment and processes.The range of Industrial Air Dryers offered by [Company Name] includes refrigerated dryers, desiccant dryers, and membrane dryers, each with its unique features and capabilities to address different air drying requirements. The refrigerated dryers are designed to lower the dew point of the compressed air, while desiccant dryers use adsorption to effectively remove moisture from the air. Membrane dryers, on the other hand, utilize selective permeation to dehydrate the compressed air stream.In addition to its standard air drying systems, [Company Name] also offers custom-designed solutions to meet the specific needs of its customers. The company's team of experienced engineers and technical experts work closely with clients to understand their unique air drying requirements and provide tailored solutions that deliver optimal performance and efficiency.One of the key strengths of [Company Name] Industrial Air Dryers is their energy-efficient design, which helps reduce operating costs and minimize environmental impact. By incorporating advanced technologies and innovative engineering, the company's air drying systems are able to deliver superior performance while consuming less energy, making them a cost-effective and sustainable choice for industrial applications.Furthermore, [Company Name] is committed to ensuring the reliability and durability of its air drying systems. The company uses high-quality components and materials, along with rigorous testing and quality control processes, to manufacture air dryers that are built to withstand the demands of industrial environments and deliver long-term, trouble-free operation.As a customer-centric company, [Company Name] places a strong emphasis on providing exceptional service and support to its clients. From initial consultation and system design to installation, commissioning, and after-sales service, the company works closely with customers to ensure that they receive the right air drying solution for their needs and that their systems continue to operate at peak performance.With a solid reputation for delivering top-quality air drying solutions, [Company Name] has established itself as a trusted partner for numerous industrial and commercial clients. The company's Industrial Air Dryers are widely used in various sectors, including manufacturing, automotive, food and beverage, pharmaceutical, and many others, where clean, dry compressed air is essential for efficient and reliable operations.In conclusion, [Company Name] Industrial Air Dryers offer advanced, energy-efficient, and reliable air drying solutions for a wide range of industrial applications. With a focus on quality, performance, and customer satisfaction, the company continues to be a leading provider of air drying systems, serving the needs of industries that rely on clean, dry compressed air for their operations.

Efficient Rotary Screw Compressor with Integrated Dryer: Enhancing Air Compression Performance

article about how this compressor can benefit businesses and industries.In today's competitive business landscape, it's essential to invest in reliable and efficient equipment that can help ensure smooth operations and consistent productivity. One example of such equipment is the Rotary Screw Compressor With Dryer. This machine is widely used in various industries due to its excellent performance and versatility. It is designed to provide compressed air to power the machinery and tools that businesses rely on to thrive.One of the standout features of this compressor is the built-in dryer. This ensures that the compressed air is free from moisture, which can cause damage to equipment and negatively impact product quality. The dryer removes the moisture from the air, ensuring that it is clean and dry. This feature can be particularly beneficial for industries that require clean compressed air, such as food and beverage production, pharmaceuticals, and medical device manufacturing.The Rotary Screw Compressor With Dryer is also known for its energy efficiency. It has a low power consumption compared to other similar machines, which can help businesses save on electricity costs. Thanks to its advanced technology, this compressor can provide consistent compressed air flow while consuming less energy. This makes it an ideal choice for businesses that require a reliable and cost-effective solution for their compressed air needs.The machine is also low maintenance, with minimal parts requiring regular servicing. This helps businesses save money on maintenance costs, as well as reducing downtime due to repairs. The compressor is designed to be easy to use and operate, with intuitive controls that can be easily understood by operators.In addition to these benefits, the Rotary Screw Compressor With Dryer is also known for its durability. It is built to withstand the rigors of daily use, with robust components that can handle high-pressure applications. This means that businesses can rely on this compressor to perform consistently for years to come, even in challenging environments.The versatility of this machine is another significant advantage. It can be used in a wide variety of applications, from powering pneumatic tools to providing compressed air for industrial processes. Businesses can choose from a range of models with different capacities and specifications, allowing them to select a compressor that meets their specific needs.The Rotary Screw Compressor With Dryer is also designed with safety in mind. It features safety guards, emergency stop buttons, and other safety features that help ensure operator safety. In industries where safety is a top priority, such as mining and construction, this compressor can be an excellent choice for businesses that need to protect their workers.Overall, the Rotary Screw Compressor With Dryer is a versatile and reliable machine that can benefit businesses across various industries. Its energy efficiency, low maintenance, and durability make it an excellent investment for businesses that require compressed air for their operations. With this compressor, businesses can enjoy consistent productivity, cost savings, and improved safety.

Revolutionary Screw Compressor: A Game-Changer in the Electric Industry

Title: Next-Generation Electric Screw Compressor Revolutionizes Industrial Air Compression: A Breakthrough by [Company Name]Introduction:[Company Name], a leading innovator in industrial air compression technology, has unveiled its game-changing Electric Screw Compressor. This revolutionary piece of machinery is set to transform the way industries across the globe operate by providing unmatched efficiency, reliability, and environmental sustainability in air compression.Overview of the Electric Screw Compressor:The Electric Screw Compressor, developed by [Company Name], marks a significant leap forward in industrial air compression technology. It combines state-of-the-art engineering with cutting-edge innovative features to create a compressor that stands out from its counterparts. By eliminating the need for traditional combustion engines, this compressor delivers exceptional performance while maintaining minimal environmental impact.Efficiency Redefined:The Electric Screw Compressor redefines efficiency in industrial air compression by incorporating advanced algorithms, smart control systems, and optimized hardware configurations. These features work in unison to minimize energy consumption, reducing operational costs, and maximizing overall productivity. Unlike traditional compressors that rely on fossil fuels, the Electric Screw Compressor operates solely on electricity, removing the need for fuel storage, transport, and associated hazards.Unrivaled Reliability:Built with precision engineering and high-quality components, the Electric Screw Compressor ensures unmatched reliability and durability. Its innovative design minimizes wear and tear, thus reducing the frequency of maintenance and enhancing its lifespan. In addition, the smart control systems constantly monitor the compressor's performance, detecting and resolving issues in real-time to prevent costly downtime for businesses.Eco-Friendly Solution:As sustainability becomes a global priority, the Electric Screw Compressor leads the way in reducing emissions and minimizing environmental impact. By operating exclusively on electricity, it eliminates harmful emissions such as greenhouse gases and polluting particulates, leading to cleaner air and a healthier work environment. With its exceptional energy efficiency, this compressor also helps companies reduce their carbon footprint, aligning with their sustainability goals.User-Friendly Interface:The Electric Screw Compressor features a user-friendly interface that simplifies operation and monitoring. Equipped with a comprehensive control panel, operators can easily access vital information such as pressure levels, temperature, and power usage. The intuitive interface also allows for seamless adjustments and customization to cater to specific needs and requirements, ensuring optimum performance.Safety Assurance:Prioritizing the safety of operators and surrounding personnel, [Company Name]'s Electric Screw Compressor integrates several safety measures. From advanced sensors that detect abnormalities to automatic shutdown protocols in case of emergencies, this compressor offers peace of mind during operation. Furthermore, the elimination of combustion engines significantly reduces fire hazards, making it a safer choice for industrial environments.Versatility in Application:The Electric Screw Compressor is designed to cater to a wide range of industrial applications. From automotive manufacturing and chemical plants to food processing and pharmaceutical industries, this compressor adapts effortlessly to diverse air compression needs. Its versatility allows businesses across various sectors to enhance production efficiency while reducing costs and environmental impact.Conclusion:The introduction of [Company Name]'s Electric Screw Compressor marks a significant milestone in the industrial air compression industry. With its outstanding efficiency, reliability, and focus on sustainability, this compressor is set to revolutionize industrial operations worldwide. As businesses increasingly prioritize environmental responsibility and operational excellence, the Electric Screw Compressor emerges as the go-to solution for efficient, eco-friendly, and high-performance air compression.[Company Name]'s commitment to innovation and dedication to creating cutting-edge technology redefines the future of industrial air compression — a future that moves towards a sustainable, highly efficient, and environmentally responsible industry.

Heavy Duty Industrial Air Compressor for heavy-duty tasks

Industrial Heavy Duty Air CompressorIndustrial heavy-duty air compressors are crucial for a wide range of applications in various industries, including manufacturing, aerospace, automotive, and construction. These powerful machines are designed to provide high-pressure air to power tools, machinery, and equipment, making them essential for the smooth operation of industrial processes.One of the leading providers of industrial heavy-duty air compressors is [Company Name]. With a strong focus on quality, performance, and reliability, [Company Name] has carved a niche for itself in the market. The company's range of industrial heavy-duty air compressors is known for its robust construction, efficient operation, and long service life, making it the preferred choice for industrial businesses worldwide.[Company Name] offers a diverse range of industrial heavy-duty air compressors to cater to the specific needs of different industries. These compressors are designed to deliver high-pressure air with maximum efficiency, allowing businesses to optimize their operations and minimize downtime. The company's commitment to innovation and engineering excellence ensures that its air compressors are equipped with the latest technologies and features, making them a valuable asset for industrial businesses.One of the key factors that set [Company Name] apart from its competitors is its dedication to customer satisfaction. The company's team of experts works closely with each client to understand their requirements and provide customized solutions that meet their needs. Whether it's for a small-scale operation or a large industrial facility, [Company Name] has the expertise and resources to deliver top-quality industrial heavy-duty air compressors that exceed expectations.In addition to its range of standard industrial heavy-duty air compressors, [Company Name] also offers a comprehensive range of accessories and spare parts to support its customers. This includes filters, hoses, fittings, and other components that are essential for the smooth and reliable operation of air compressors. This commitment to providing complete solutions sets [Company Name] apart as a trusted partner for industrial businesses looking for reliable air compressor solutions.Furthermore, [Company Name] takes pride in its after-sales support and maintenance services. The company's team of technicians and engineers are equipped with the knowledge and expertise to provide timely service and support for its industrial heavy-duty air compressors. This includes regular maintenance, troubleshooting, and repair services to ensure that the air compressors continue to operate at peak performance throughout their service life.With a strong emphasis on quality, performance, and customer satisfaction, [Company Name] continues to be a leading provider of industrial heavy-duty air compressors in the market. The company's commitment to innovation and excellence has earned it a reputation as a reliable and trusted partner for industrial businesses across the globe.In conclusion, industrial heavy-duty air compressors play a crucial role in the functioning of various industrial processes, and [Company Name] has established itself as a leading provider of these essential machines. With a focus on quality, performance, and customer satisfaction, the company's range of industrial heavy-duty air compressors and comprehensive support services make it the preferred choice for industrial businesses looking for reliable and efficient air compressor solutions.

Explore Variable Speed Lubricated Rotary Screw Compressors for Optimum Performance

Variable Speed Screw Compressors: How They Work and Their BenefitsWhen it comes to industrial air compression, variable speed screw compressors have become increasingly popular for their efficiency and ease of use. Whether you're looking to save on energy costs or improve the performance of your operation, a variable speed screw compressor might be the solution you need.So, how do variable speed screw compressors work?As the name suggests, these compressors feature a motor that can adjust its speed to meet the changing demands of your operation. When demand is low, the motor operates at a lower speed, which reduces energy consumption and wear on the compressor. As demand increases, the motor speeds up, providing the necessary airflow.Compressors that operate at a fixed speed can waste energy when the demand for air drops. This is because they continue to run at full power, even if it's unnecessary. With a variable speed screw compressor, you only use as much energy as you need, which translates to lower electricity bills and a smaller carbon footprint.Another benefit of variable speed compressors is their ability to provide consistent air pressure. Unlike fixed speed models, which may experience fluctuations in pressure during use, variable speed screw compressors maintain a stable output. This helps to prevent interruptions in production due to equipment malfunctions.Advancements in technology have also made variable speed screw compressors quieter and more reliable than ever before. Thanks to innovative designs and materials, these compressors operate with lower vibrations and produce less noise, making them ideal for use in noise-sensitive environments.In addition to these benefits, variable speed screw compressors offer a range of other features that make them a smart choice for industrial air compression. Some models, for example, come equipped with advanced monitoring and reporting capabilities, which allow you to keep track of your compressor's performance in real-time and identify potential issues before they lead to downtime.Other features to look for include:- Energy-saving modes that automatically adjust compressor output based on demand- User-friendly interfaces that make it easy to adjust settings and monitor performance- Compact, space-saving designs that take up less floor space than traditional compressorsWhether you're a facility manager or an industrial engineer, upgrading to a variable speed screw compressor can help you reduce costs, increase efficiency, and improve overall air compression performance. With so many benefits and options to choose from, there's no reason not to make the switch today.Get in touch with a reputable compressor supplier to learn more about the different variable speed screw compressor models available and find the perfect compressor that meets the demands of your operation.